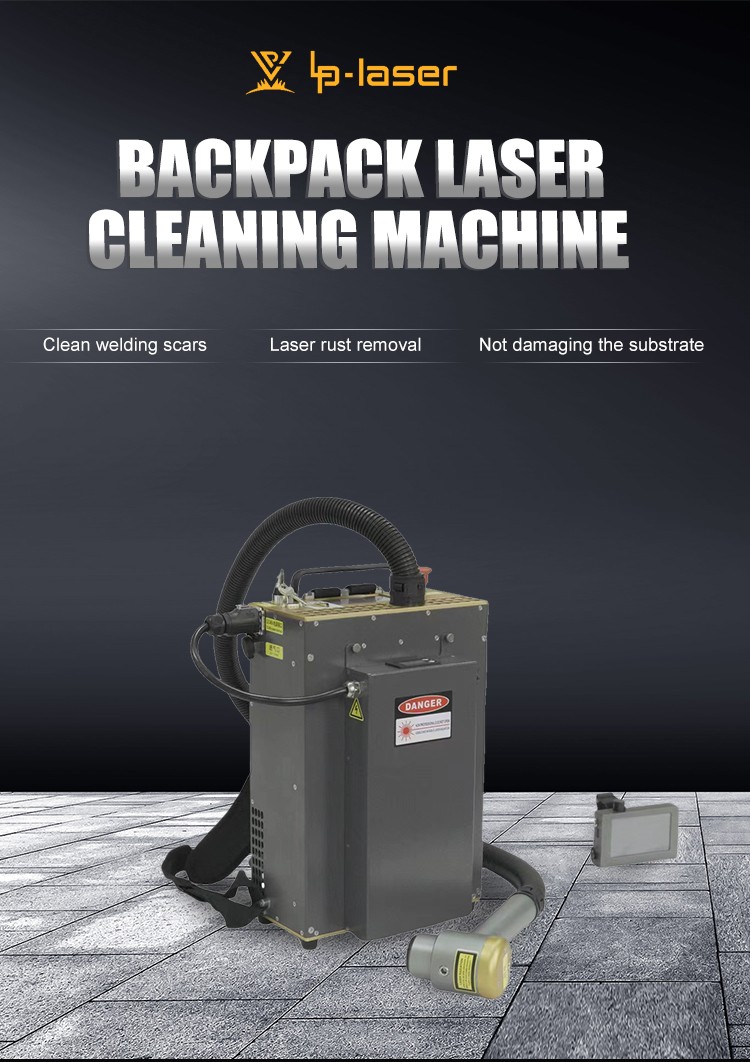

Factory direct supply Backpack Laser Cleaning Machine

Portable & Ergonomic Design

Lightweight backpack style enables easy operation in hard-to-reach areas, boosting on-site productivity.

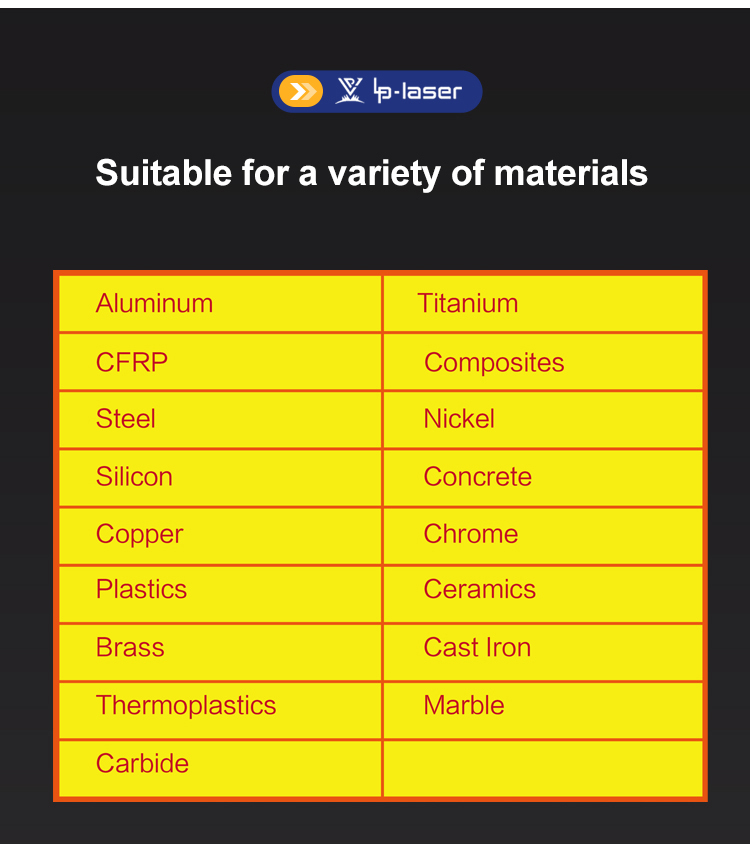

Non-Abrasive & Non-Destructive

Laser cleaning preserves substrate integrity—no damage to metals, composites, or delicate surfaces.

Eco-Friendly & Chemical-Free

Zero wastewater, abrasives, or toxic chemicals. Reduce environmental impact and comply with green regulations.

High Efficiency & Low Cost

Up to 3x faster than traditional methods (sandblasting/chemical cleaning) with minimal maintenance.

Adjustable Parameters

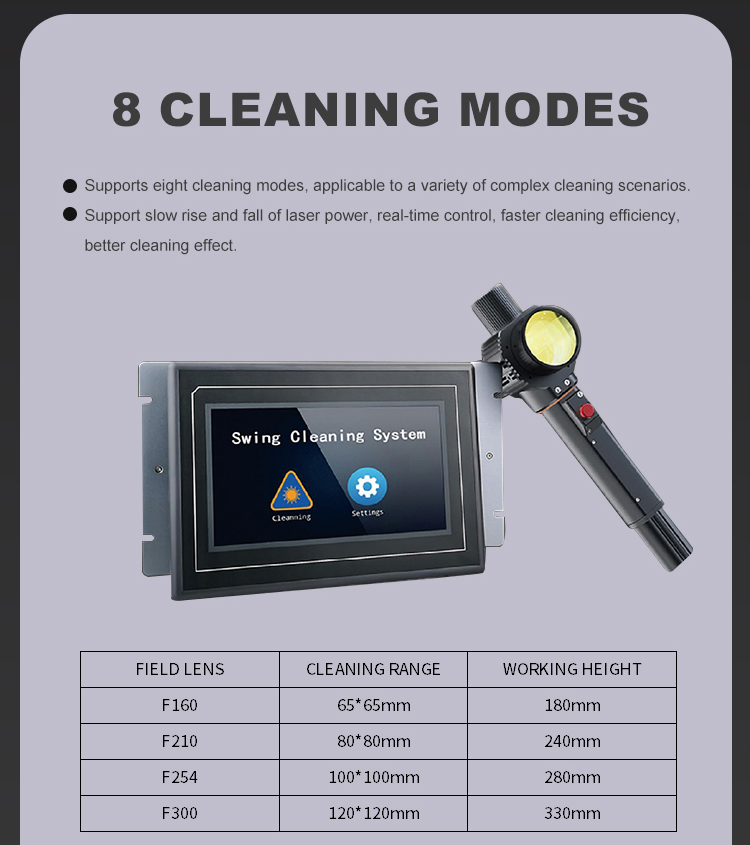

Customize power (100W-500W options), frequency, and spot size for versatile applications.

Long Service Life

Robust fiber laser source ensures 100,000+ hours of operational durability.

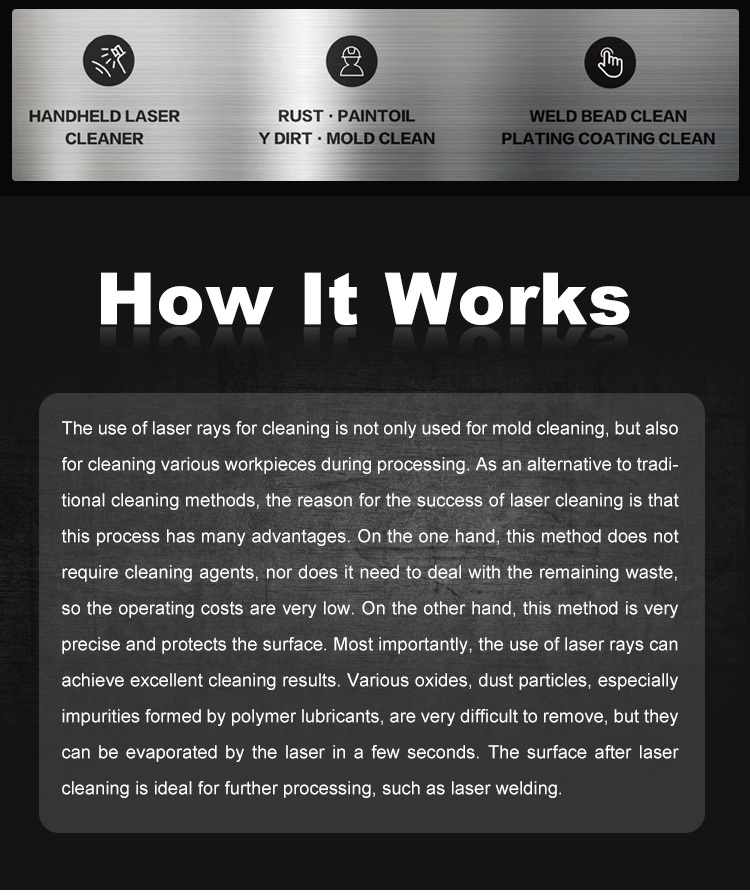

Product introduction

The use of laser rays for cleaning is not only used for mold cleaning, but also for cleaning various workpieces during processing. As an alternative to traditional cleaning methods, the reason for the success of laser cleaning is that this process has many advantages. On the one hand, this method does not require cleaning agents, nor does it need to deal with the remaining waste, so the operating costs are very low. On the other hand, this method is very precise and protects the surface. Most importantly, the use of laser rays can achieve excellent cleaning results. Various oxides, dust particles, especially impurities formed by polymer lubricants, are very difficult to remove, but they can be evaporated by the laser in a few seconds. The surface after laser cleaning is ideal for further processing, such as laser welding.

| Model: | HLC-P100W-06DHLC | HLC-P200W-06D | HLC-P300W-06D |

| Strip Rate Per Hour: | 24 ft²/h | ||

| Operational Voltage: | 220V±10%、50/60Hz Optional battery, continuous operation 80-90 minutes | ||

| Temperature: | 5℃~40℃ | ||

| Humidity: | 30-85% Non-Condensing | ||

| Power dissipation: | ≤600W | ≤800W | ≤1100W |

| Power Output: | 100W | 200W | 300W |

| Laser Type: | Optical fiber | ||

| Maximum Pulse Energy: | 1.7mJ | 2mJ(selectable 5mJ) | 2.0mJ(5mJ-15mJselectable) |

| Pulse Frequency Range: | 20-200kHz Gradient adjustable | 1-3000kHz Gradient adjustable | 1-3000kHz Gradient adjustable |

| Pulse Width: | 150-190ns tunable | 13-500ns tunable | 13-500ns tunable |

| Output Power Instability: | <5% | ||

| Wavelength: | 1064 nm | ||

| Head Cable Length: | 1.5 m | ||

| Cooling: | Air cooling | ||

| Focus Distance: | 160mm | 210mm | 210mm |

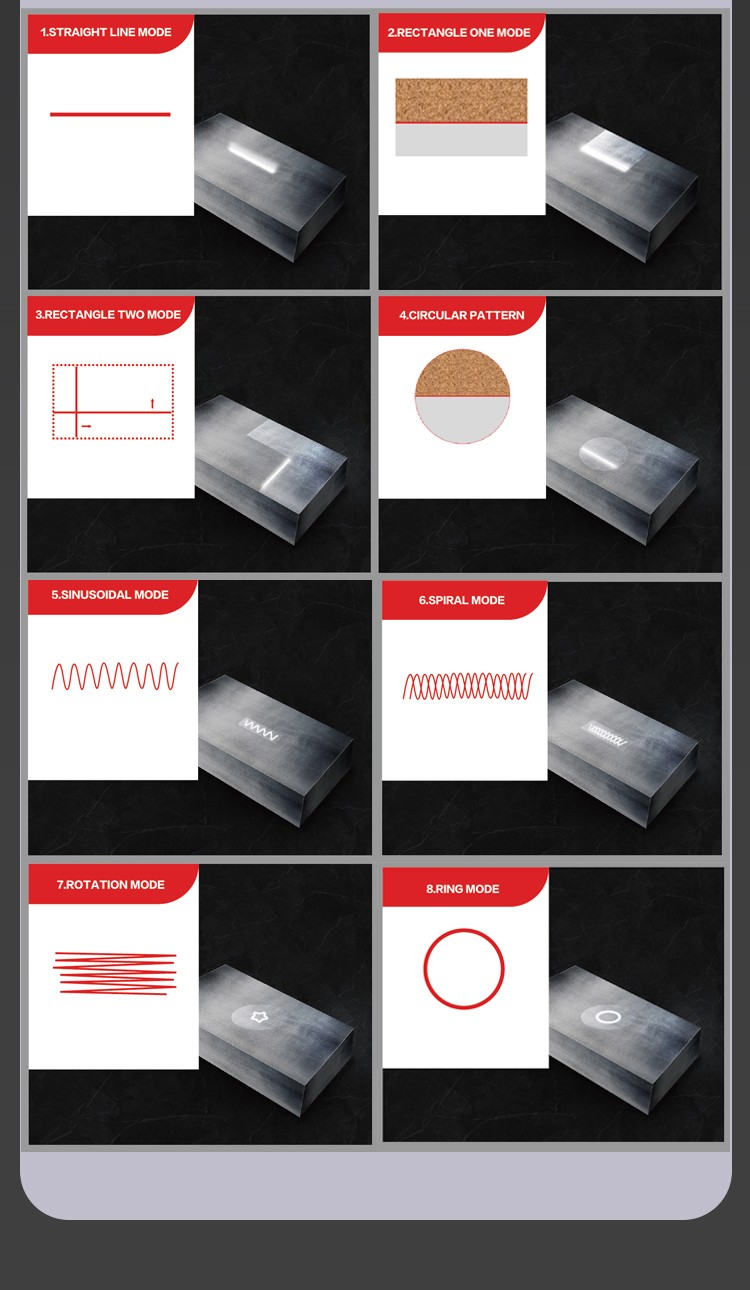

| Scanning mode: | Dual axis; Nine scanning modes are supported | ||

| Head Weight: | ≤0.9Kg | ||

| Size W x H x D: | 213mm*123mm*339mm(Battery free) | 268mm*135mm*445mm(Battery free) | |

| 213mm*168mm*339m(Battery included) | 268mm*191.5mm*445mm(Battery included) | ||

| Box Dimensions: | about 860*840*340mm | ||

| Entire Unit Weight: | about 8.5Kg(Battery free) | about12.5Kg(Battery free) | about13.47 Kg(Battery free) |

| about 12Kg(Battery included) | about17Kg(Battery included) | about18.08 Kg(Battery included) | |

| Packed weight: | about 42.1Kg(Battery free) | about 49.9Kg(Battery free) | about 51 Kg(Battery free) |

| about 45.3Kg(Battery included) | about 55.3Kg(Battery included) | about 56 Kg(Battery included) | |

| Operation Mode: | Handheld/Automation | ||

| Safety Class: | Level IV | ||

Q1: How to set parameters for paint removal?

A: Start at 100W, 20 kHz, 5 ns pulses, then adjust based on adhesion strength.

Q2: Optimal scanning speed?

A: 1-5 m/min for paint; slower for thick rust (adjust beam overlap to 30-50%).

Q3: How to clean curved surfaces?

A: Use dynamic focus lenses or robotic arms with 6-axis mobility.

Q4: Why does cleaning effectiveness vary?

A: Contamination thickness, substrate material, and humidity affect results.

Q5: How to avoid streaking?

A: Maintain consistent speed and 50% beam overlap; use galvanometer scanners for even coverage.