Durable Dot Needle Type Laser Marking Machine

1. Deep-Penetration Marking Technology

Hybrid Dot Matrix System: Laser-activated needle creates 0.2-0.5mm deep marks (3x deeper than standard lasers)

No Fading Guarantee: Marks survive sandblasting, acid washing, and 1000°C heat

Perfect for Hard Metals: Works on hardened steel (HRC 60+), titanium, and cast iron

2. Industrial-Grade Reliability

50 Million+ Mark Lifespan: Tungsten carbide needle outlasts competitors by 5x

Dustproof & Oil-Resistant: IP67 rated enclosure for harsh environments

Shock Absorption System: Stable marking even on vibrating production lines

3. Unmatched Speed & Efficiency

High-Speed Mode: 15 characters/second (ideal for production lines)

Auto-Depth Adjustment: Instantly adapts to material hardness

Continuous 24/7 Operation: Water-cooled laser system prevents overheating

4. Smart Industrial Features

PLC Integration: Direct connection to assembly line controllers

Automated Datamatrix: Generates compliant 2D codes for traceability

Remote Diagnostics: Real-time monitoring via IoT platform

Dot Needle Type Laser Marking Machine

Permanent Industrial Marking with Unmatched Durability

Product Overview

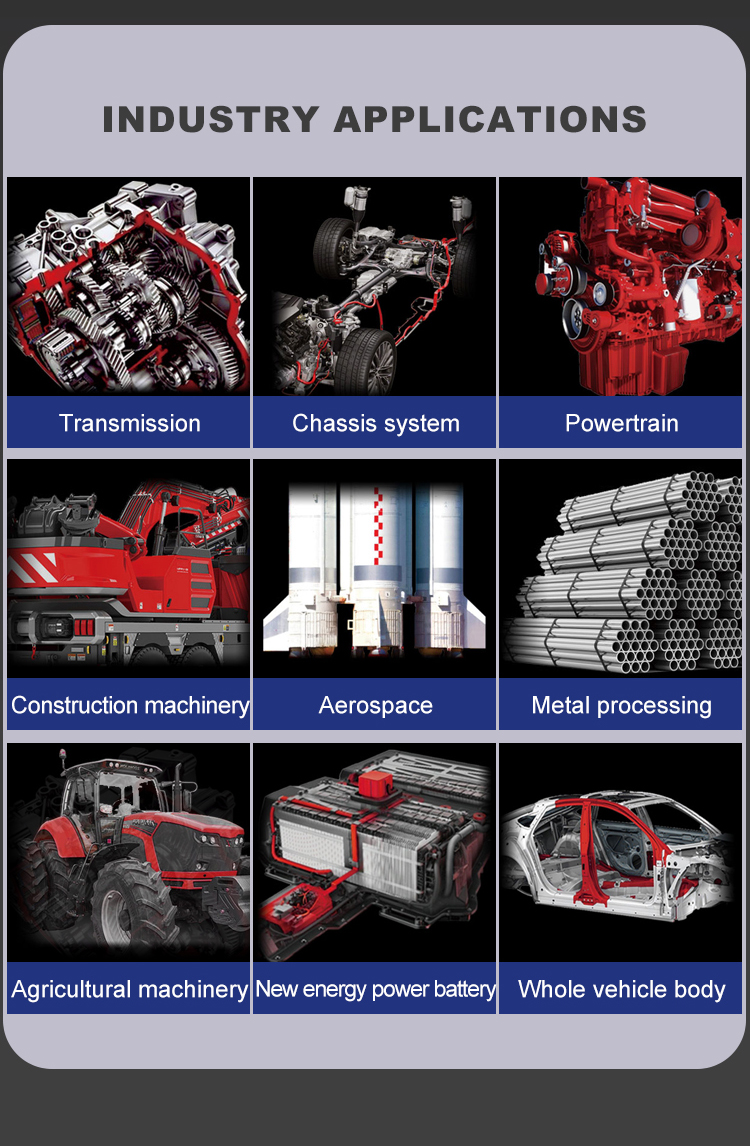

Our Dot Needle Type Laser Marking Machine combines the deep penetration of dot peen marking with the precision of laser technology, creating the most durable identification marks for heavy-duty industrial applications. Engineered for automotive VIN plates, construction machinery, military equipment, and oil/gas components, this system delivers indestructible markings that withstand extreme environments.

| Model | EM-100x170 |

| Type | Electric、 Hand Held、Dot Peen、 marking |

| Controller | Built-In Software and Touch Screen |

| Marking Area | 100mm x170mm |

| Marking Speed | 1-4 characters/s (5mm height) |

| Marking Depth | 0.1mm-1mm(according to material) |

| Power supply | AC 100V -240V 50HZ/60HZ |

| Marking Content | English characters, number, all kinds of graphicoutline, logo, dot matrix 2D codes, Barcode, SeriaNumber, circle Letter and etc. |

| Power dissipation | <400W |

A: Yes, we can help you integrate the marking machine into your existing production line. We have experience in designing and implementing solutions for seamless integration. This may involve customizing the machine's control system to communicate with other equipment on the production line and ensuring proper positioning for efficient marking operations.

Q2: What are some common problems with marking machines and how can I solve them?

A: Some common problems include the machine not starting, which could be due to power issues, software glitches, or control system failures. To solve this, check the power connection, restart the machine and software, and if the problem persists, contact our technical support. Another issue could be poor marking quality, which might be caused by incorrect parameter settings, dirty optical components (for laser machines), or low ink levels (for inkjet machines). Adjusting parameters, cleaning components, or refilling ink can often resolve these problems.

Q3: Are replacement parts easily available for your marking machines?

A: Yes, we keep a sufficient inventory of replacement parts for all our marking machines. In case you need a replacement part, you can contact our customer service, and we will ensure that the part is shipped to you as soon as possible. We also provide guidance on how to replace the part if it is a simple task that can be done by the user.