High Performance Portable Dot Marking Machine

High - Precision Marking

Dot peen marking machines are capable of achieving remarkable precision. They can create marks with an accuracy of up to 0.1 mm or even better in some advanced models. This high level of precision ensures that the marked information is clear, legible, and consistent. Whether it's marking small, intricate parts in the electronics industry or larger components in the automotive sector, the precision of dot peen marking machines allows for the creation of highly detailed and accurate marks. For instance, in the production of micro - electronic components, the ability to mark tiny serial numbers or identification codes with such precision is essential for quality control and traceability.

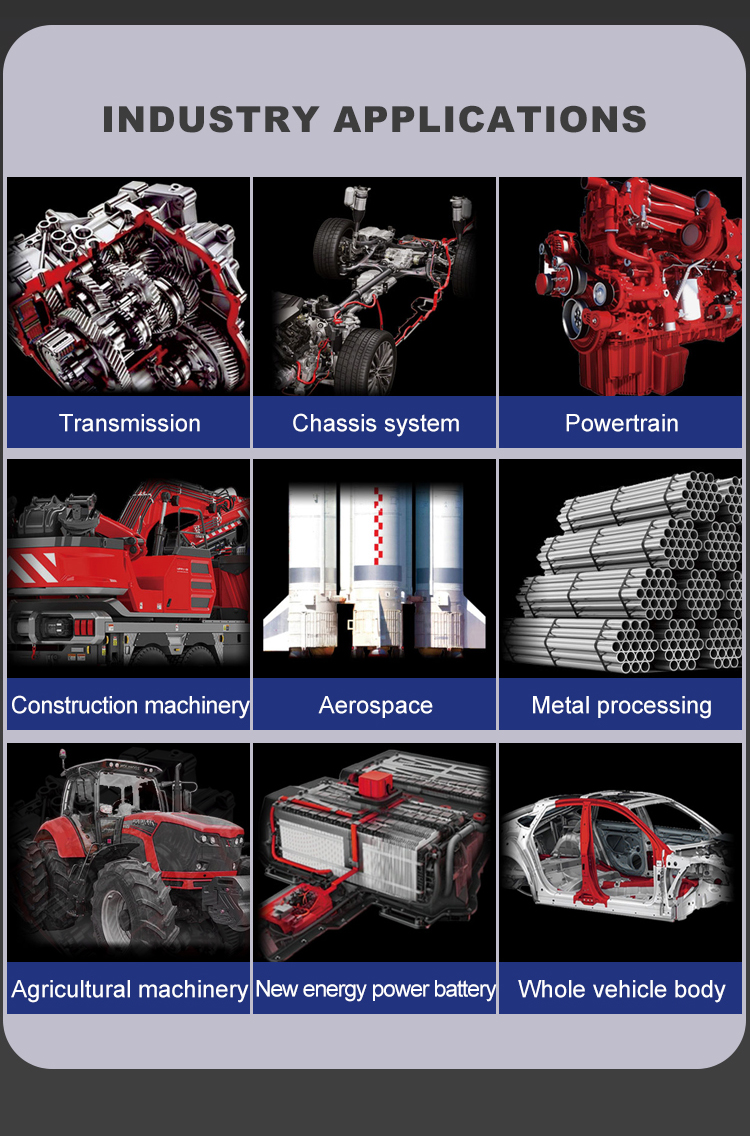

Versatile Material Compatibility

These machines can mark a wide range of materials. They are particularly well - suited for metals, including stainless steel, carbon steel, aluminum, copper, and brass. However, they are also effective on various plastics, such as polycarbonate, ABS, and nylon, as well as on hard rubbers and some ceramics. This versatility makes them invaluable in industries where different materials are used in the manufacturing process. In the aerospace industry, for example, dot peen marking machines can be used to mark both metal aircraft components and plastic interior parts with relevant identification and tracking information.

Adjustable Marking Depth

One of the significant advantages of dot peen marking machines is the ability to adjust the marking depth. Depending on the application and the material being marked, operators can control the depth of the indentations created by the stylus. For applications where a more prominent and long - lasting mark is required, such as on industrial machinery parts that are exposed to harsh environments, a deeper mark can be made. On the other hand, for more delicate materials or where a subtler mark is sufficient, the depth can be reduced. This adjustability allows for customization of the marking to meet specific industry standards and product requirements. In the medical device industry, for example, a shallow mark may be sufficient for marking plastic components, while a deeper mark may be needed for metal implants to ensure long - term readability.

Durable and Reliable Construction

Dot peen marking machines are built to withstand the rigors of industrial use. They are constructed with high - quality materials, such as robust metal frames and corrosion - resistant components. The stylus, which is the key component for marking, is often made from extremely hard materials like tungsten carbide or diamond - tipped alloys. This ensures long - lasting performance even when marking hard materials. Additionally, the mechanical and electromagnetic components of the machine are designed for durability and reliability, minimizing the risk of breakdowns and ensuring consistent operation over extended periods. In a high - volume manufacturing facility, the reliable operation of dot peen marking machines is crucial to maintain production efficiency.

Easy to Operate and Program

Most modern dot peen marking machines come with user - friendly interfaces and intuitive software. Operators can easily input the marking content, select fonts, adjust the size and orientation of the marks, and set other parameters through a simple control panel or a computer - based interface. The software also often includes features such as the ability to import graphics and logos from common file formats, making it convenient to create custom - designed marks. Even those with limited technical knowledge can quickly learn to operate these machines effectively after a short training period. For example, in a small - scale metalworking shop, the operator can use the user - friendly interface to input part numbers and batch information for marking on metal products without much difficulty.

Cost - Effective Solution

Compared to some other marking technologies, such as laser marking in certain applications, dot peen marking machines offer a cost - effective option. They generally require less initial investment in equipment, and their operating costs are relatively low. The only significant consumable is the occasional replacement of the stylus, which is a cost - effective part. Additionally, their durability and low maintenance requirements contribute to long - term cost savings, making them an attractive choice for small to medium - sized enterprises as well as large - scale manufacturing facilities. In a cost - conscious manufacturing environment, the cost - effectiveness of dot peen marking machines can significantly impact the overall production budget.

Dot Peen Marking Machine Introduction

In the landscape of industrial identification and traceability solutions, dot peen marking machines have emerged as a reliable and versatile option. These machines are designed to create permanent and highly legible marks on a wide variety of materials, playing a crucial role in numerous industries.

Working Principle

Dot peen marking machines operate based on a straightforward yet effective principle. The core of the process involves a mechanical or electromagnetic system that drives a carbide or diamond - tipped stylus. This stylus is made to strike the surface of the material to be marked at a high frequency.

When the machine is activated, the stylus rapidly impacts the workpiece's surface. Each strike creates a small indentation or dot. By precisely controlling the movement of the stylus in the X and Y axes, as well as the frequency and force of the strikes, a series of dots are formed in a specific pattern. This pattern can represent text (such as serial numbers, part numbers, or manufacturing dates), graphics, barcodes, or 2D data matrix codes. For example, in a metal fabrication plant, the dot peen marking machine can be programmed to mark a unique serial number on each metal component. The machine's control system coordinates the stylus movement, ensuring that the dots are placed accurately to form the desired characters.

Q1: Why does your 200W system clean faster than competitors' 300W?

A: Our beam quality (M²<1.1) delivers 40% higher energy density, making every watt count.

Q2: How do you achieve more consistent results?

A: Real-time surface monitoring with CCD cameras automatically adjusts power 10,000 times/second.

Q3: Why is your cleaning precision better?

A: Galvanometer scanners with 0.001° accuracy enable micron-level control - crucial for aerospace applications.

Q4: How does your fume extraction outperform?

A: Integrated HEPA+activated carbon filtration captures 99.97% of nanoparticles - others require add-ons.

Q5: Why do your lenses last longer?

A: Diamond-coated optics withstand 5x more cleaning cycles than standard lenses.