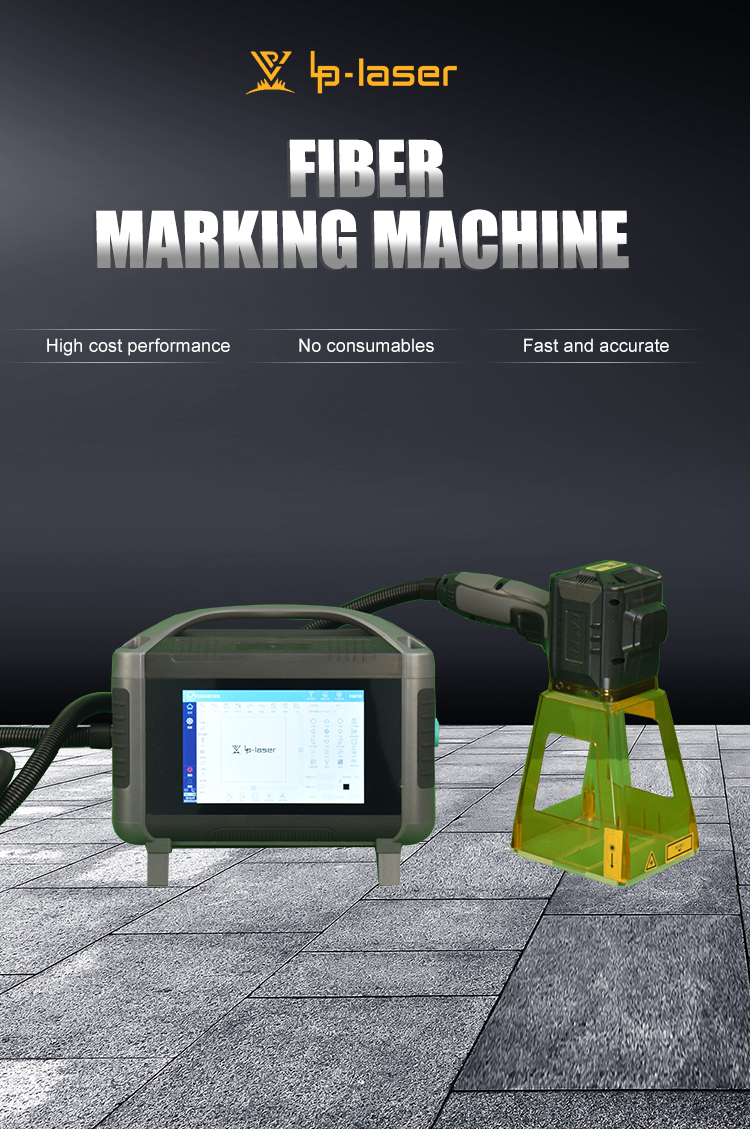

Reliable Durable Fiber Marking Machine

High Precision

With a marking accuracy that can reach the micron level, fiber marking machines are capable of creating extremely fine and detailed marks. This high precision is crucial for applications where product traceability, brand identification, or intricate design requirements are essential. Whether it's marking small electronic components or creating elaborate patterns on jewelry, the fiber marking machine ensures clear and sharp markings.

Fast Marking Speed

Equipped with high - speed scanning galvanometer systems, fiber marking machines can achieve rapid marking speeds. This significantly increases production efficiency, allowing for high - volume output in a short period. For example, in a mass - production setting, the fast marking speed can reduce the overall production time and cost per unit, making it an ideal choice for large - scale manufacturing.

Wide Material Compatibility

Fiber marking machines are highly versatile when it comes to material compatibility. They can effectively mark a vast range of materials, including metals (such as stainless steel, aluminum, copper, and even rare metals), plastics, ceramics, and some non - metallic materials. This adaptability eliminates the need for multiple specialized marking machines for different materials, providing cost - savings in terms of equipment investment and maintenance.

Long Service Life

The fiber laser in these machines has an impressively long lifespan, often reaching up to 100,000 hours. The absence of many moving parts and the use of a robust, all - fiber structure contribute to their durability. A long service life means fewer replacements and less downtime for machine replacement and setup, ultimately reducing long - term operating costs.

Energy - Efficient

Fiber marking machines are designed to be energy - efficient. They consume relatively low power, typically less than 200W, which is significantly lower than traditional marking machines. Additionally, their air - cooled cooling system eliminates the need for complex and energy - consuming liquid cooling systems, further reducing energy costs and maintenance requirements related to cooling.

Non - contact Marking

The non - contact marking method employed by fiber marking machines offers several advantages. It eliminates the risk of mechanical wear and tear on the marking head and the materials being marked. This is particularly beneficial when working with delicate or fragile materials, as it reduces the likelihood of damage and material waste. Non - contact marking also ensures consistent mark quality without any physical interference with the material surface.

Introduction

Fiber marking machines have emerged as a leading choice in the marking industry, offering a wide range of benefits for various applications. These machines utilize advanced fiber laser technology to create high - quality, permanent marks on a diverse array of materials.

Working Principle

The fiber marking machine's core component is the fiber laser. Multiple small - power air - cooled laser diodes serve as the pump source. They are coupled into a single laser fiber, and the fiber doped with rare - earth elements (such as Nd, Yb, or Er) acts as the gain medium. The resonator cavity, composed of reflective mirrors and fiber gratings, enables the generation of laser beams. These beams can operate in both pulsed and continuous - wave modes, providing flexibility for different marking requirements.

| Laser Type | Fiber Laser |

| Power | 20w/30w/50w |

| Working temperature | 0-40℃ |

| Voltage | 110V/220V AC |

| File Format | BMP,DXF,HPGL,JPEG,PLT |

| Cooling Mode | Air Cooling |

| Net Weight | 75kg |

| Languages | Chinese,English,Russia,Spanish,Korean,Japanese,Portuguese,Arabic, Turkish , etc |

| Laser Wavelength | 1064nm |

1.Q: Do I need to invest in additional training for my staff to operate the fiber marking machine at high speeds?

A: Our fiber marking machines are designed with user - friendly interfaces. While some basic training is recommended, the intuitive operation makes it easy for staff to learn how to operate the machine at high speeds without excessive training costs.

2.Q: How does the fast marking speed of fiber marking machines compare to traditional marking methods in terms of cost - savings?

A: Compared to traditional methods, fiber marking machines can complete marking tasks much faster. This reduces labor costs associated with manual or slower - paced marking processes, and also enables quicker turnover of products, resulting in significant cost savings.

3.Q: Why are the maintenance costs of fiber marking machines relatively low?

A: Fiber marking machines have a simple and robust structure with few moving parts. The fiber laser has a long lifespan and doesn't require frequent component replacements. Additionally, the air - cooled system eliminates the need for complex liquid cooling system maintenance.