Handheld Laser Welding Machine

Handheld Laser Welding Machine Features:

Water-cooled

Liquid-cooled

Equipped with a water cooling system

Cooled by water circulation

Cost-effective

Economical

Budget-friendly

Affordable yet efficient

Provides excellent value for money

High power

High-performance output

Powerful laser capacity

Delivers substantial energy output

High-intensity welding capability

Product Description:

A portable laser welding machine is a compact device engineered for situations where welding needs to be done on - the - move or for small - scale projects. Traditional welding techniques like arc welding operate by using electrodes to create an electrical arc between the base material and the welding rod. However, laser welding functions in a distinct way. It makes use of a highly focused laser beam. This beam has the power to melt metals, which then join together as they cool.

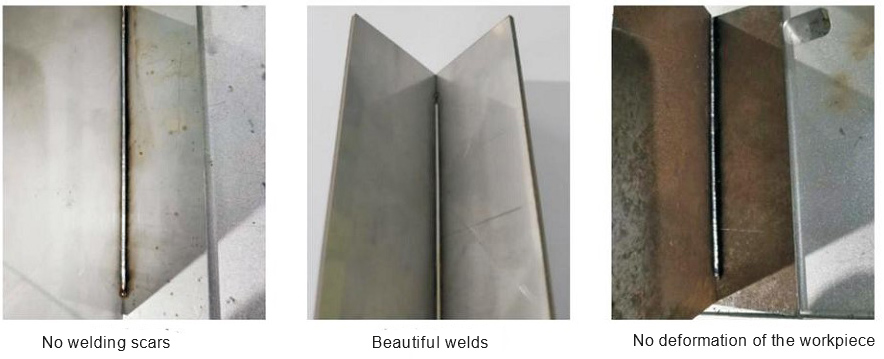

Sample Photos:

Technical Parameters:

Model: | HLW-1500W | HLW-2000W | HLW-3000W |

Operational Voltage: | 220V±10%、50/60Hz | ||

Temperature: | 5℃ ~41℃ | ||

Humidity: | 30-85% Non-Condensing | ||

Power dissipation: | ≤7.7KW | ≤9.5KW | ≤14.5KW |

Power Output: | 1500W | 2000W | 3000W |

Operating Mode: | Continuous w | ||

Laser Type: | fibre | ||

Max modulation frequency: | 10kHz | ||

Output Power Instability: | <5% | ||

Wavelength: | 1080±10 nm | ||

Head Cable Length: | 5±0.5 m | ||

Cooling: | water cooling | ||

Swing width: | 0~5mm | ||

Head Weight: | ≤0.91Kg | ||

Protective gas: | Inert gases (nitrogen, argon) | ||

Size W x H x D: | 1200×630×1160mm | 1200×630×1160mm | 1200×630×1160mm |

Box Dimensions | 1260×720×1350mm | 1260×720×1350mm | 1260×720×1350mm |

Entire Unit Weight: | 180Kg | 220Kg | 260Kg |

Packed weight: | Kg | ||

Operation Mode: | handhold | ||

Safety Class: | Level IV | ||

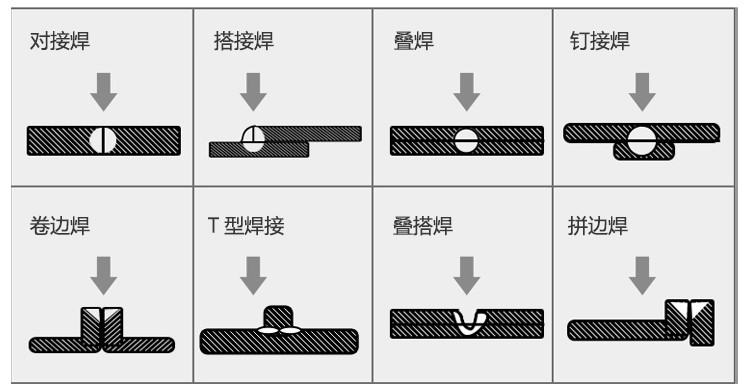

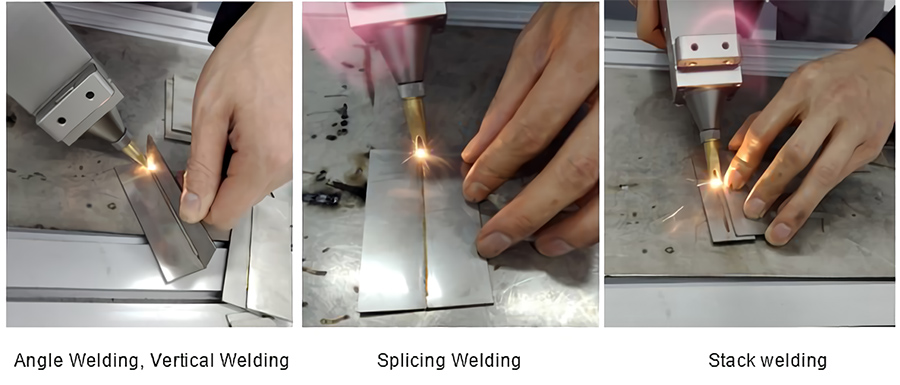

Welding Method:

Welding Depth:

power | stainless steels | carbon steel | galvanised sheet | aluminium | brass | pure copper |

1000W | 3mm | 3mm | 3mm | 2mm | 1.5mm | 1mm |

1500W | 4mm | 4mm | 4mm | 3mm | 2mm | 1.5mm |

2000W | 5mm | 5mm | 5mm | 4mm | 2.5mm | 2mm |

3000W | 6mm | 6mm | 6mm | 5mm | 3mm | 2.5mm |

Use Cases: (handheld/automation):

FAQ

1.Q: How does the performance of a laser welding machine justify its relatively high initial cost?

A: Laser welding machines offer superior welding quality with high precision, speed, and consistency. Their non - contact operation reduces the risk of damage to workpieces, minimizing rework and material waste. The long - term savings in production efficiency, reduced labor costs, and lower defect rates make the initial investment worthwhile.

2.Q: Are laser welding machines energy - efficient, and how does it affect cost - effectiveness?

A: Yes, laser welding machines are energy - efficient. Advanced laser sources and control systems ensure that energy is used only when needed during the welding process. Lower energy consumption not only cuts down on electricity bills but also reduces the overall operating cost, enhancing the machine's cost - effectiveness over time.

3.Q: Can the high - speed welding of laser welding machines improve production efficiency and reduce costs?

A: Absolutely. Laser welding machines can achieve extremely high welding speeds compared to traditional welding methods. This significantly increases the throughput of the production line, allowing manufacturers to produce more products in less time. With higher production volumes, the cost per unit decreases, directly improving the overall cost - effectiveness of the manufacturing process.