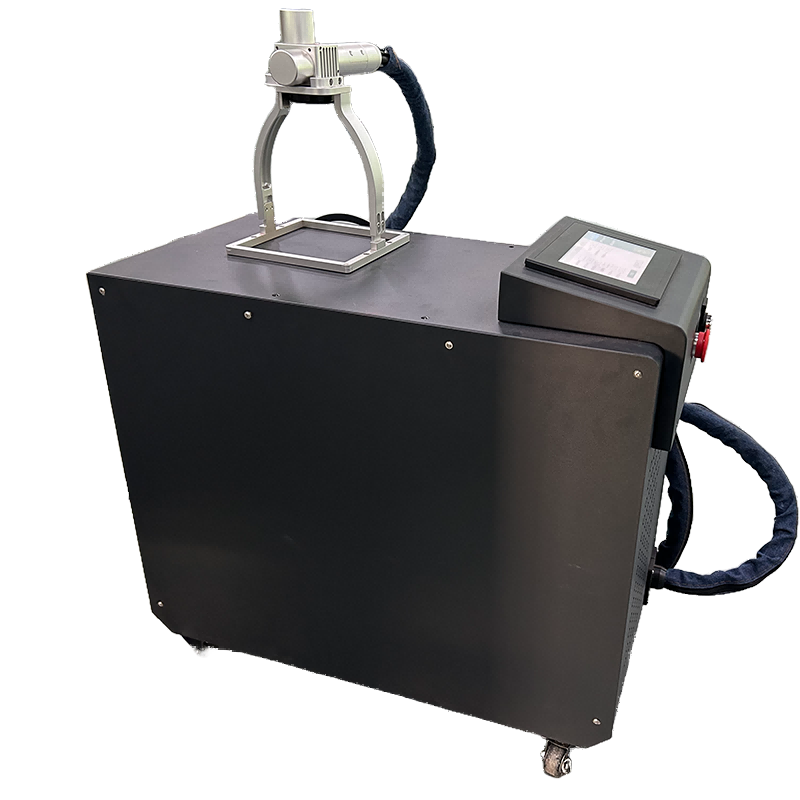

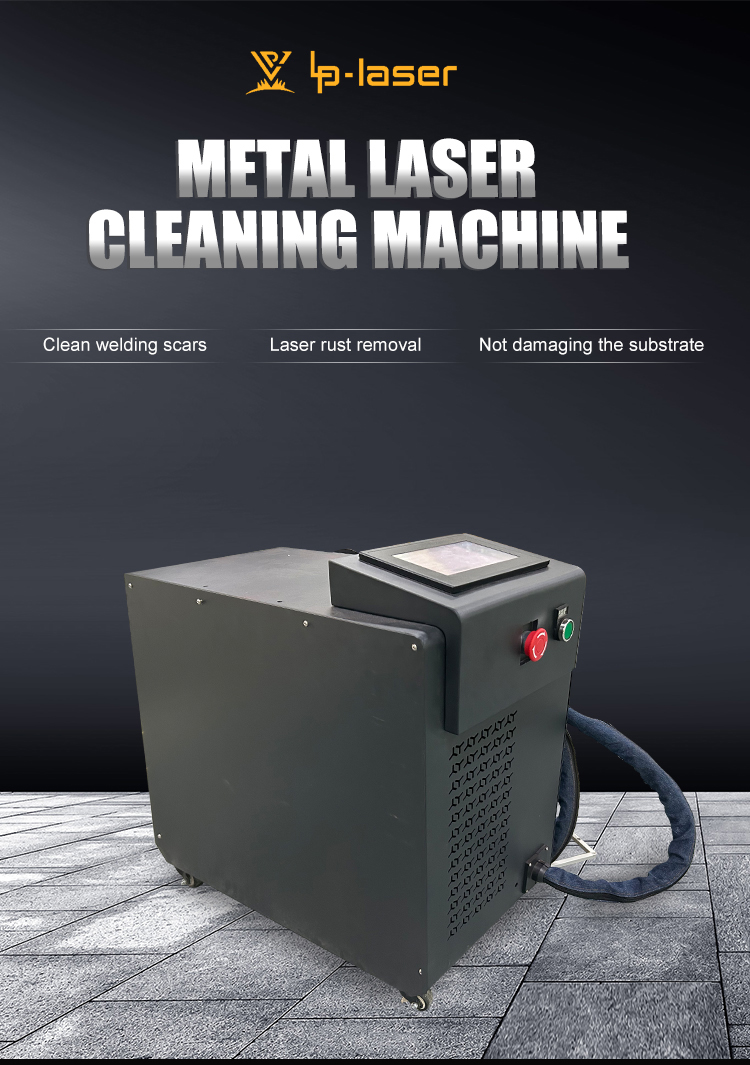

High Quality Metal Laser Cleaning Machine

1. High Precision and Selectivity

Metal laser cleaning machines offer unrivaled precision. The laser beam can be accurately focused on specific areas of the metal surface.

2.Non - Abrasive and Non - Contact

3.Environmentally Friendly

4.High Efficiency

5.Cost - Effective Long - Term

6.Versatile

7.Minimal Thermal Impact

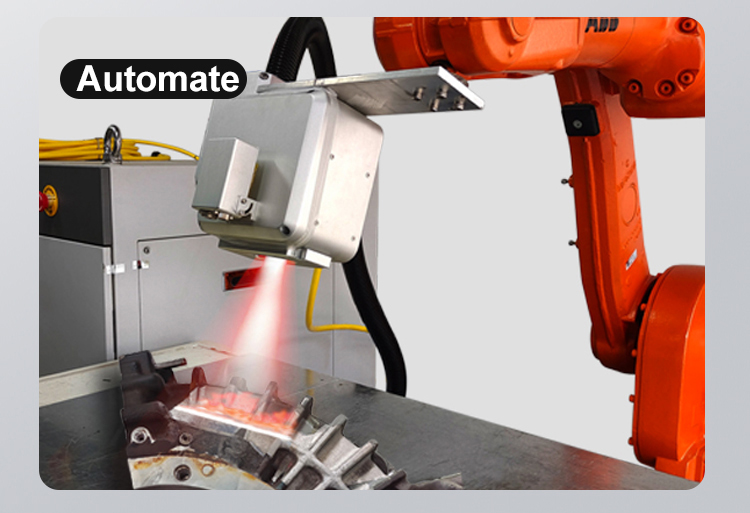

8.Easy to Integrate and Automate

Product introduction

Laser ablation cleaning has rapidly expanded beyond mold maintenance, becoming a versatile solution for precision surface preparation across diverse industrial applications. As a revolutionary advancement over conventional cleaning methods, its success stems from unparalleled performance and operational benefits.

1. Eco-Friendly & Cost-Efficient Operation

Unlike traditional chemical-based approaches, laser cleaning eliminates the dependency on hazardous solvents and the logistical challenges of waste disposal. This not only slashes operational expenses but also streamlines workflows, making it a greener, more sustainable alternative with minimal environmental impact.

2. Unmatched Precision & Surface Integrity

Through advanced beam focusing and energy modulation, laser ablation enables selective material removal with micron-level accuracy. The non-contact nature of the process ensures no mechanical stress or surface deformation, preserving the workpiece’s structural integrity while achieving superior cleaning outcomes—even on delicate components.

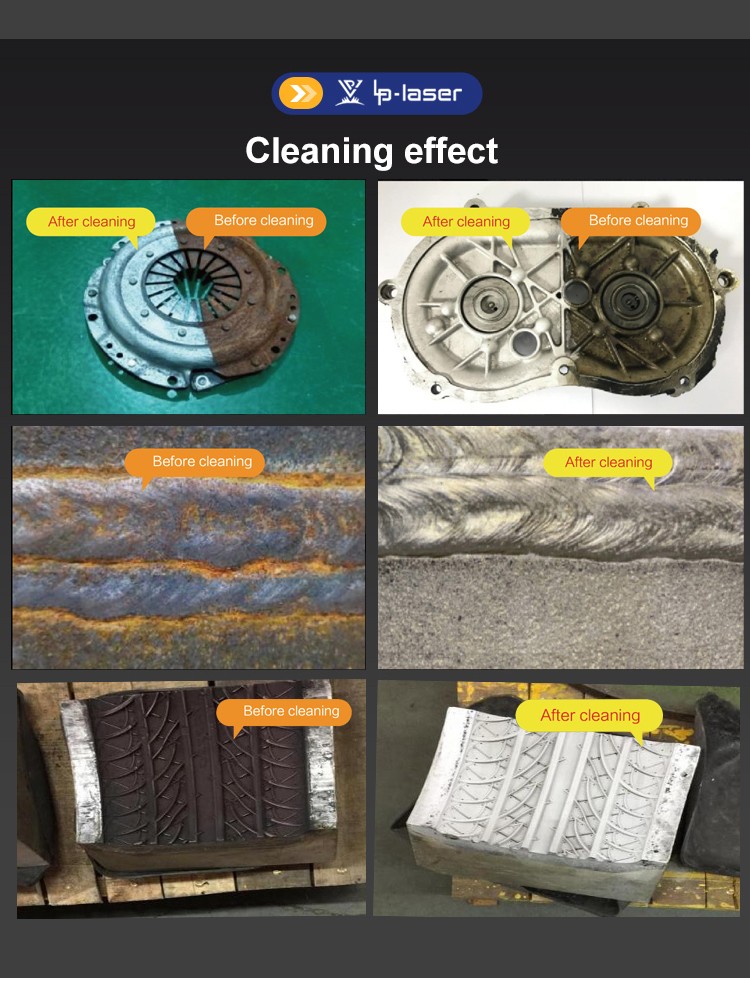

3. Superior Cleaning Efficacy for Complex Contaminants

The technology excels at removing tenacious residues such as oxide layers, embedded particulates, and carbonized residues from polymer lubricants. These stubborn contaminants are effectively vaporized via localized photothermal effects, leaving behind a pristine surface free of micro-defects or residue.

4. Enhanced Process Integration & Efficiency

Post-laser cleaning surfaces exhibit exceptional smoothness and cleanliness, eliminating the need for secondary preparation steps like degreasing or abrasion. This seamless compatibility with downstream processes—such as laser welding or coating—significantly boosts production throughput and final product quality.

| Model: | HLC-P100W | HLC-P200W |

| Operational Voltage: | 220V±10%、50/60Hz Customizable: 110V, 50Hz AC | |

| Temperature: | 5℃~40℃ | |

| Humidity: | 30-85% Non-Condensing | |

| Power dissipation: | ≤1000W | ≤1500W |

| Power Output: | 100W | 200W |

| Laser Type: | Optical fiber | |

| Maximum Pulse Energy: | 1.5mJ | 1.5mJ |

| Pulse Frequency Range: | 1-3000kHz(Gradient adjustable) | 1-3000kHz(Gradient adjustable) |

| Pulse Width: | 13-500ns tunable | 13-500ns tunable |

| Output Power Instability: | <5% | |

| Wavelength: | 1064 nm | |

| Head Cable Length: | 3 m | 3 m |

| Cooling: | Air cooling | |

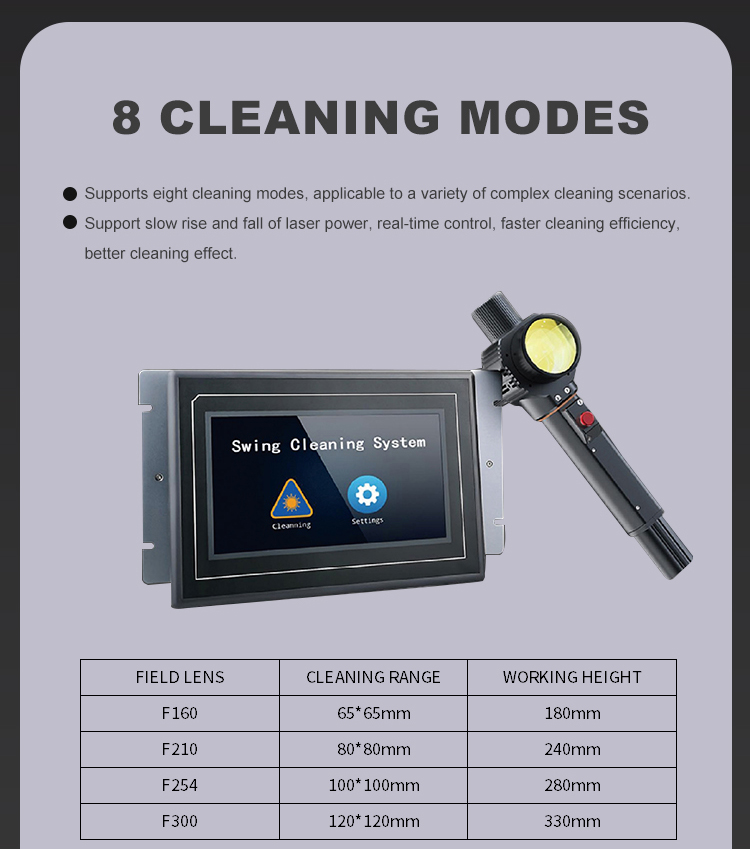

| Focus Distance: | 160mm | 254mm |

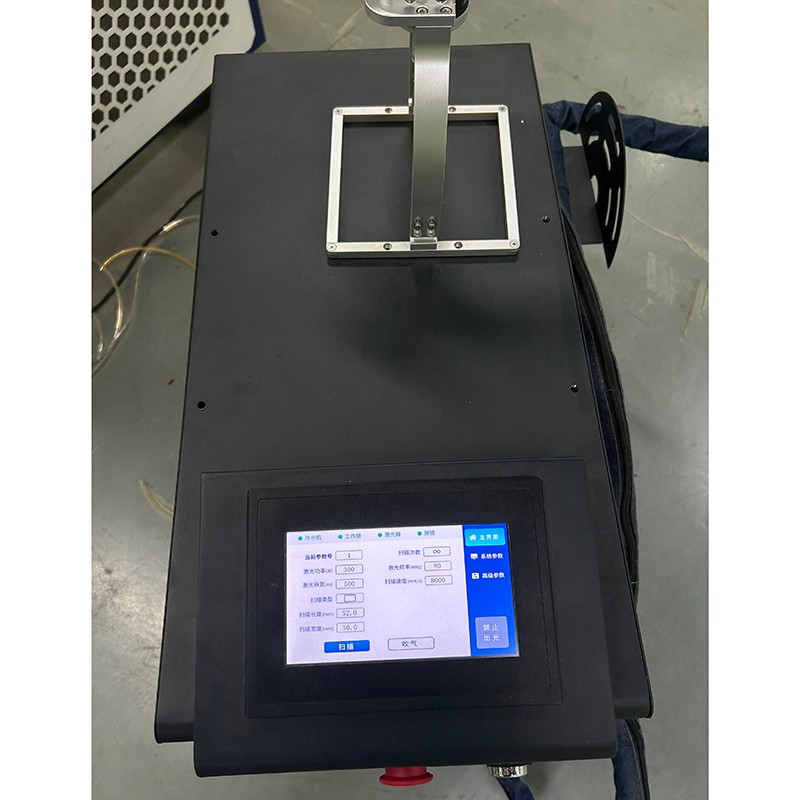

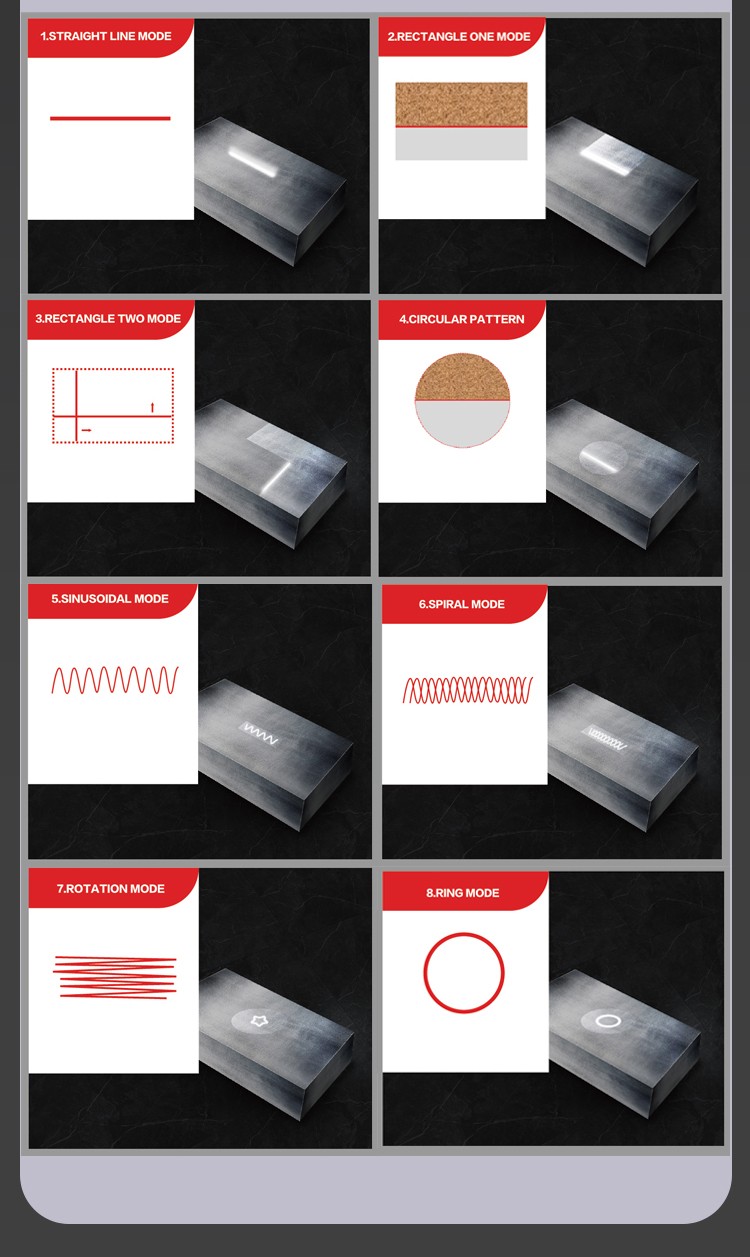

| Scanning mode: | Dual axis; Nine scanning modes are supported | |

| Head Weight: | ≤0.9Kg | ≤0.9Kg |

| Size W x H x D: | About350mm*152mm*250mm | |

| Box Dimensions | ||

| Entire Unit Weight: | About 12Kg | About 18Kg |

| Packed weight: | About 20Kg | About 26Kg |

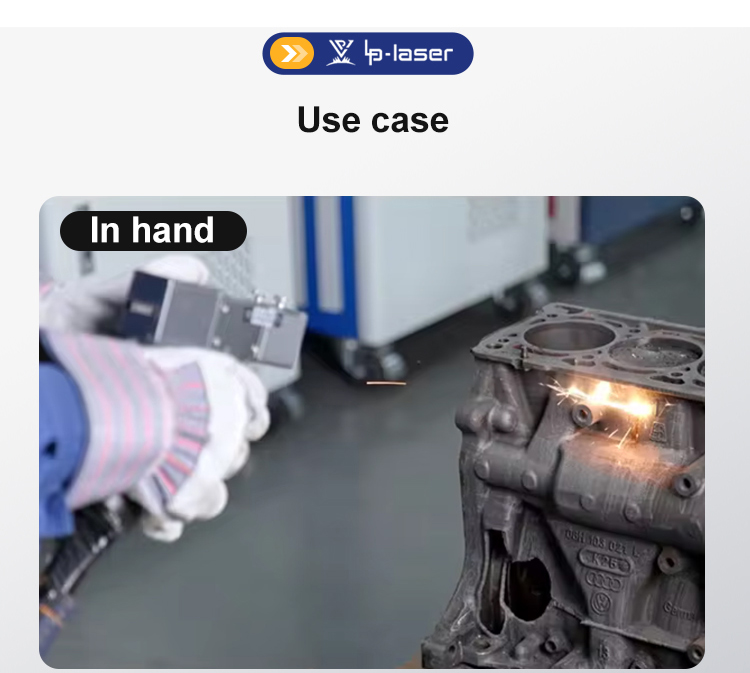

| Operation Mode: | Handheld/Automation | Handheld/Automation |

| Safety Class: | Level IV | Level IV |

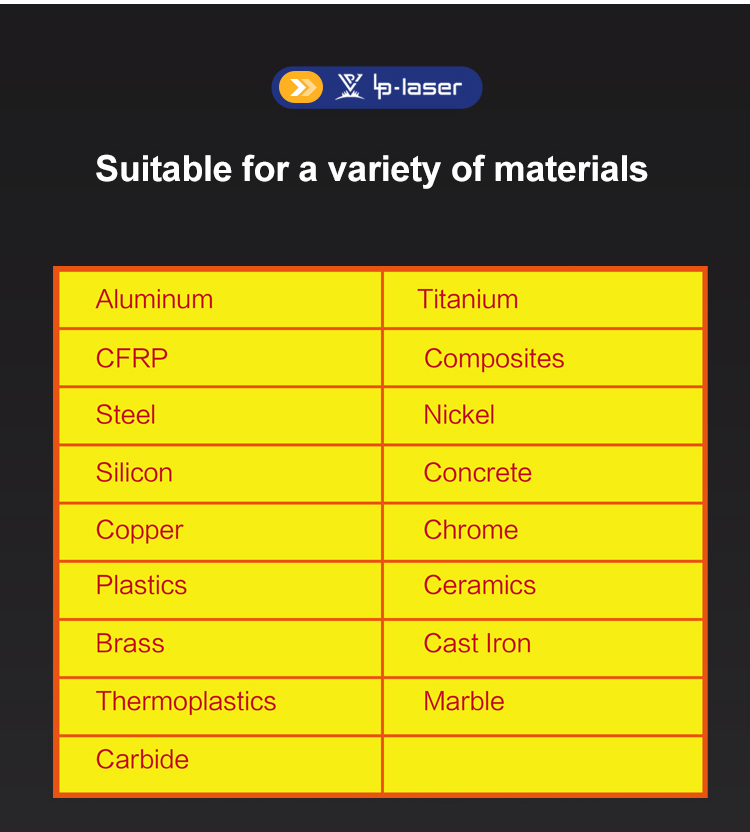

1. What materials can be cleaned with a laser cleaner?

Aluminium - Carbon fibre reinforced plastics - Steel - Silicon - Copper - Plastic - Copper - Thermoplastics -Titanium - composite materials - nickel - chromium - ceramics - cast iron - marble - carbide, etc.

2. Is there any damage to the cleaning material?

Pulse type has finer cleaning effect while continuous type has faster cleaning speed, relative to material damage, pulse type is less than continuous type. By optimising the algorithm and increasing the speed, we can achieve basically no damage to the substrate.

3. How many cleaning modes are currently supported?

Currently, we support 9 modes: Linear, Rectangle I, Rectangle II, Circle, Sine, Spiral, Free, Circle and Rotary.

3. Language interface

Currently support Chinese, Chinese traditional, English, Russian, Japanese, Spanish, German, Korean, French and other 16 languages

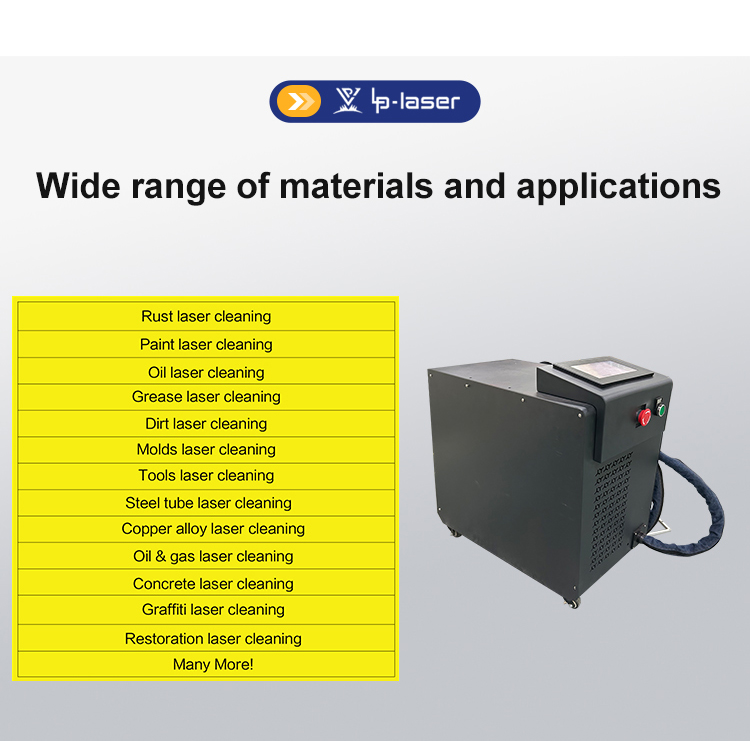

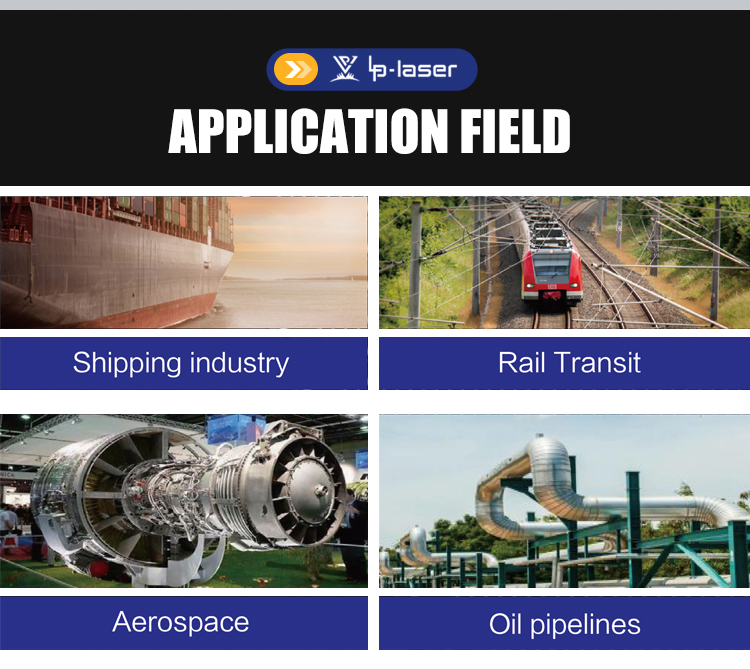

4.Product Application

This machine is suitable for removing all kinds of stains, including rust layer, paint, oil, coating, oxidation layer, adherence on stone statues (detailed to dust level), and rubber moulding residue. In addition, it is also suitable for pre-treatment of welded/painted surfaces.