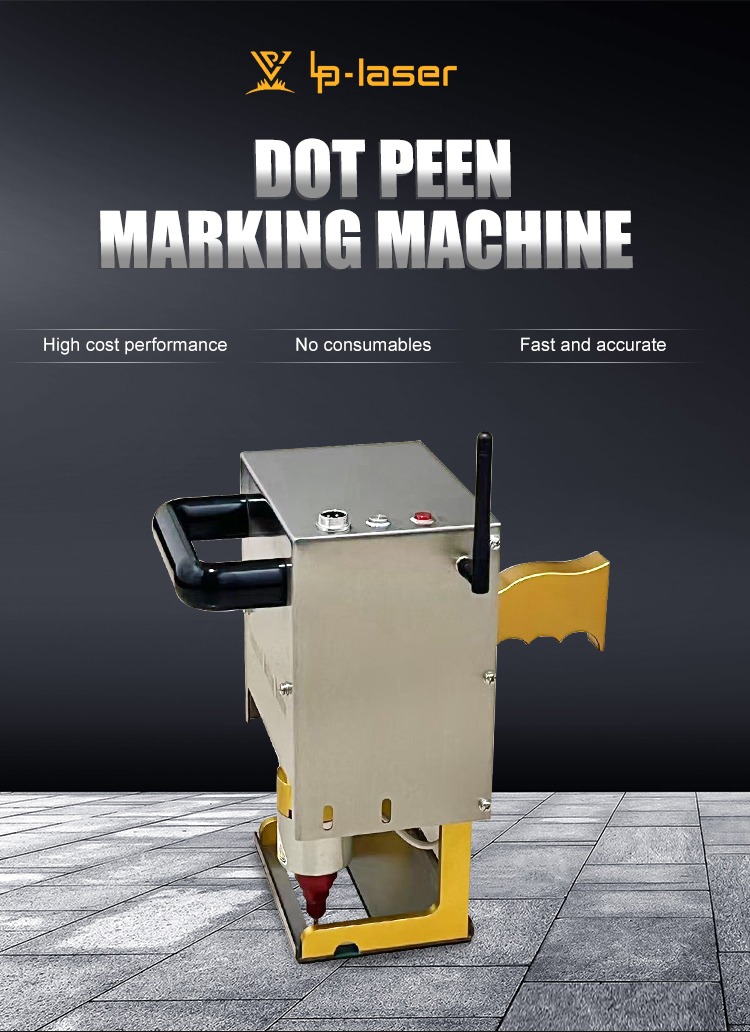

High Quality Point-Point Handheld Laser Marking Machine

1. Unmatched Precision & Control

True Point-to-Point Technology: Laser head moves precisely between programmed coordinates (not freehand) for CNC-level accuracy (±0.02mm)

Adjustable Focal Length: Maintains clarity on uneven surfaces (curved pipes, angled tools)

Micro-Marking Capable: Perfect for <1mm text or 2D codes on small components

2. Handheld Flexibility + CNC Accuracy

Hybrid Operation:

Handheld Mode: For quick marks in hard-to-reach areas

Fixed CNC Mode: Mounts to workbench for automated batch processing

Real-Time Positioning Display: Integrated screen shows marking path to prevent errors

3. Industrial-Grade Durability

Shockproof & IP54 Rated: Withstands workshop environments (dust, oil, vibrations)

All-Metal Laser Head: 10x longer lifespan than plastic competitors

No Consumables: Eliminates costs of inks, tips, or stencils

4. Smart Connectivity

Wi-Fi/Bluetooth: Syncs with ERP/MES systems for instant serial number updates

Offline Database: Stores 10,000+ designs (logos, templates, serial sequences)

Cross-Platform Software: Windows, iOS, and Android compatible

Point-to-Point Handheld Laser Marking Machine

Precision Marking Where You Need It

Product Overview

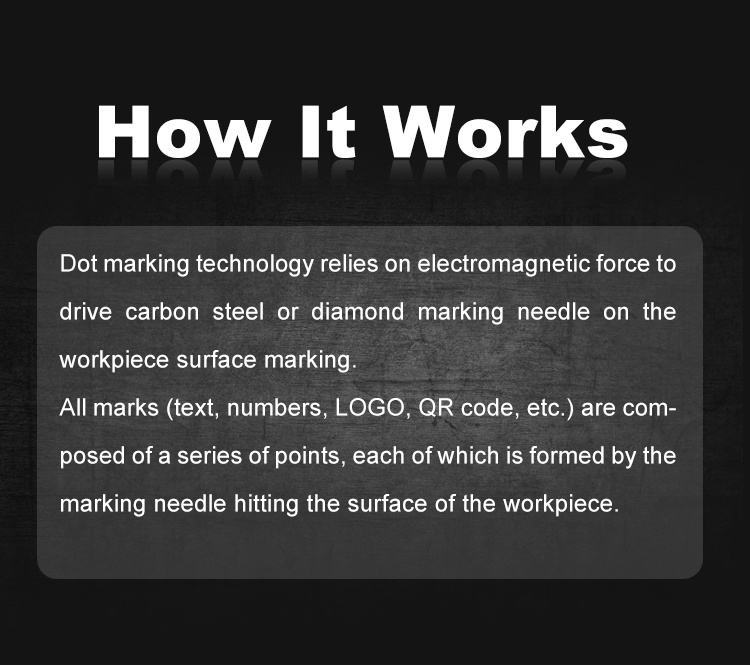

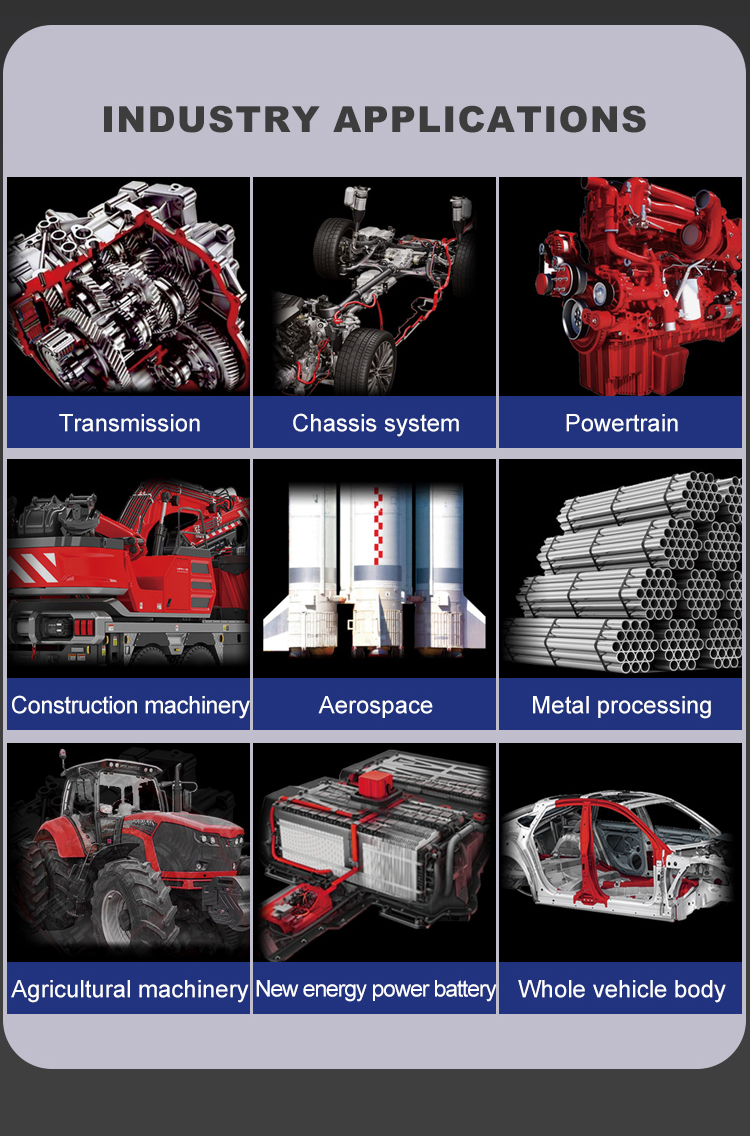

Our Point-to-Point Handheld Laser Marking Machine revolutionizes industrial marking with its ultra-precise point-to-point laser technology, combining the flexibility of handheld operation with the accuracy of CNC-controlled marking. Ideal for aerospace components, automotive parts, tool identification, and medical devices, this system delivers permanent, high-contrast marks without surface deformation.

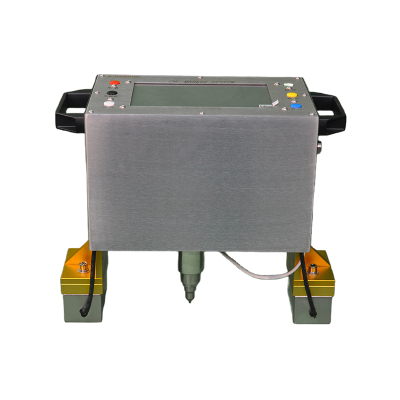

| Model | EM-40x90 |

| Type | Electric、 Hand Held、Dot Peen、 marking |

| Controller | Built-In Software and Touch Screen |

| Marking Area | 40mm x 90mm |

| Marking Speed | 1-4 characters/s (5mm height) |

| Marking Depth | 0.1mm-1mm(according to material) |

| Power supply | AC 100V -240V 50HZ/60HZ |

| Marking Content | English characters, number, all kinds of graphicoutline, logo, dot matrix 2D codes, Barcode, SeriaNumber, circle Letter and etc. |

| Power dissipation | <400W |

Q1: How often should I clean the laser lens?

A: Clean the lens weekly (or daily in dusty environments) with alcohol wipes to maintain marking quality.

Q2: What routine maintenance does a laser marker need?

A: Check optics alignment, clean ventilation filters, inspect cables, and lubricate moving parts (if applicable).

Q3: Can I upgrade my laser’s power later?

A: Some manufacturers offer power upgrades, but it depends on the machine model. Consult your supplier beforehand.

Q4: What software is used to control laser markers?

A: Most machines use proprietary or universal software (e.g., EzCad, LightBurn) compatible with DXF, AI, or BMP files.

Q5: How do I troubleshoot blurred markings?

A: Recalibrate the focus lens, check for contamination, ensure correct focal distance, and verify material flatness.