Handheld Laser Cleaning Machine

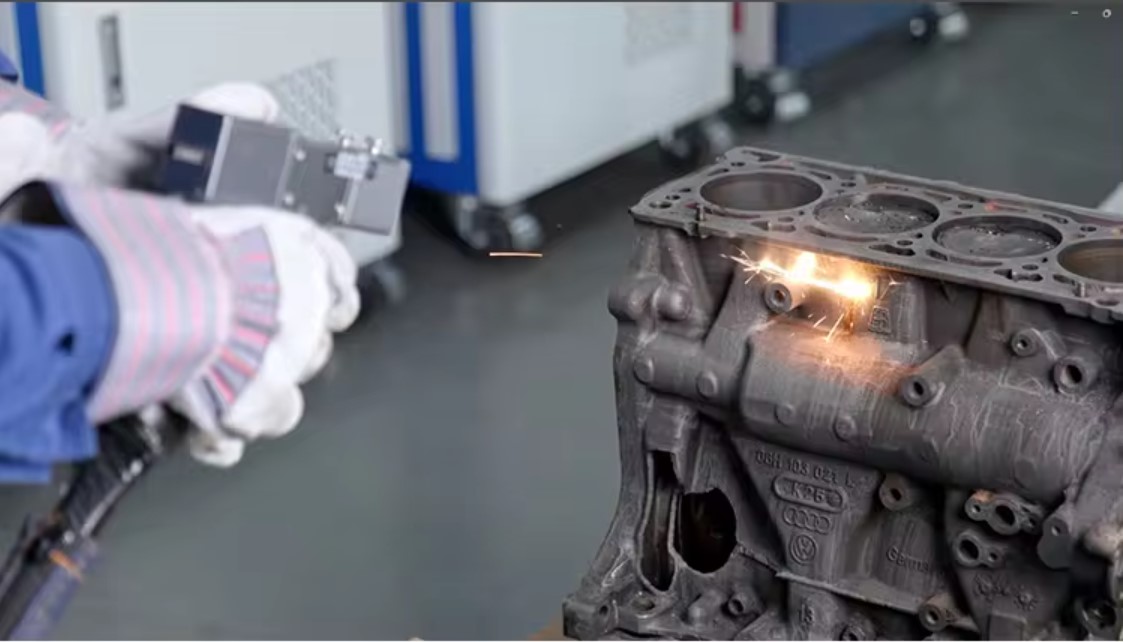

1.Portability: As the name suggests, these machines are designed to be handheld and lightweight, allowing for easy maneuverability and use in various locations, including those that are hard to reach or where larger equipment cannot be used.

2.Ease of Use: Handheld laser cleaning machines are typically user-friendly, with simple controls and a straightforward operation process. This makes them accessible to operators with varying levels of experience.

3.Non-Abrasive Cleaning: The laser cleaning process is non-abrasive, meaning it does not use brushes, chemicals, or other physical means to remove contaminants. This helps to preserve the integrity of the cleaned surface.

4.Adjustable Parameters: Many handheld laser cleaning machines allow the operator to adjust parameters such as laser power, pulse frequency, and spot size to suit the specific cleaning requirements of different materials and levels of contamination.

How Handheld Laser Cleaning Machine Works?

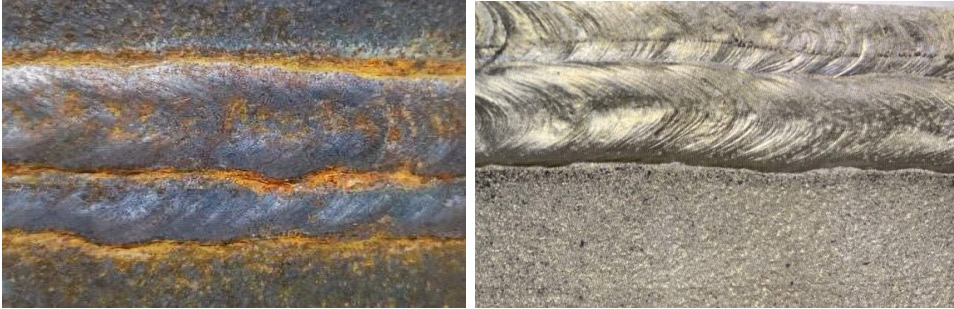

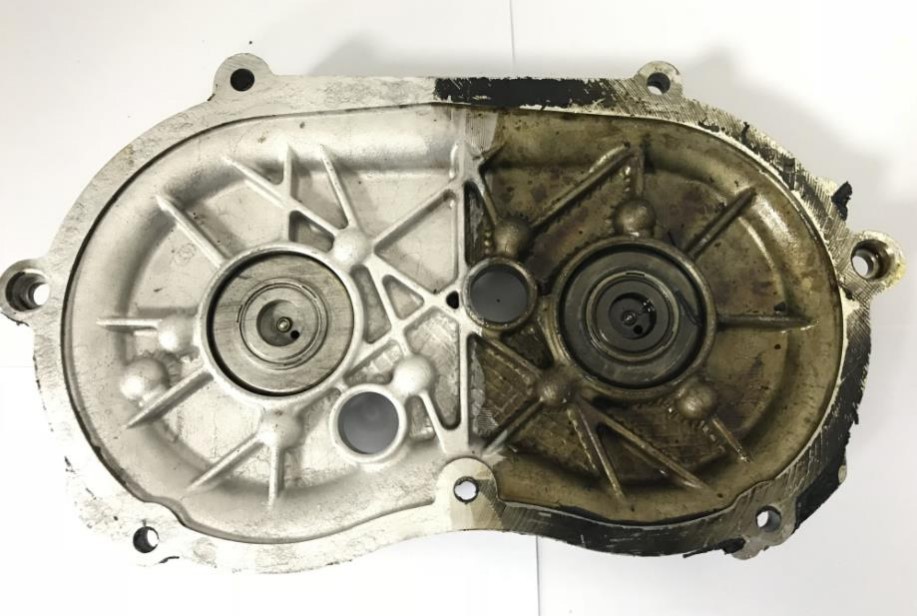

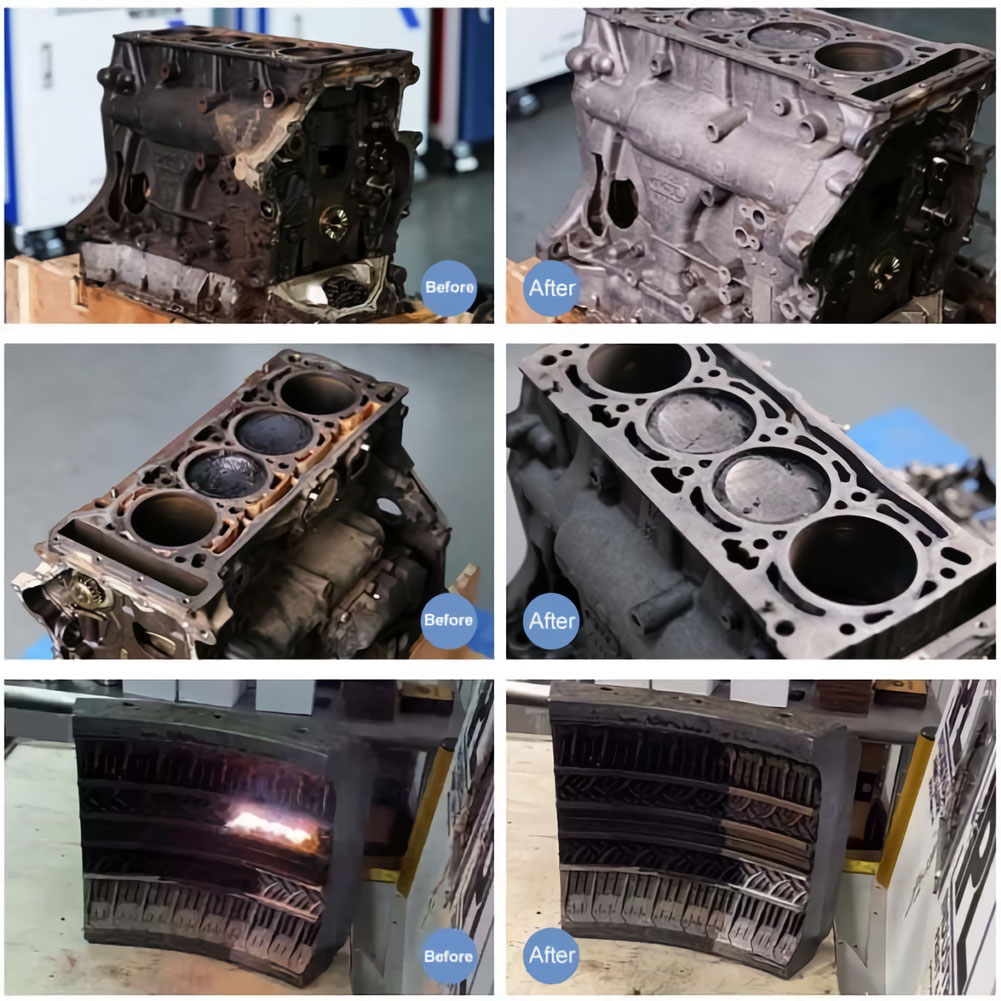

The Handheld Laser Cleaning Machine uses laser rays to clean not only moulds and dies, but also all kinds of workpieces in the process. The success of laser cleaning as an alternative to conventional cleaning methods is due to the many advantages of this process. On the one hand, it does not require cleaning agents or the disposal of residual waste, and therefore has very low operating costs. On the other hand, it is very precise and protects the surface. Above all, the use of laser rays achieves excellent cleaning results. All kinds of oxides, dust particles and especially impurities formed by polymer lubricants, which are very difficult to remove, can be evaporated by the laser in a matter of seconds. The laser-cleaned surfaces are ideally suited for further processing, such as laser welding.

Sample Photos:

Product Parameter:

Model: | HLC-P100W | HLC-P200W |

Operational Voltage: | 220V±10%、50/60Hz customisable:110V、50Hzalternating current | |

Temperature: | 5℃ ~40℃ | |

Humidity: | 30-85% Non-Condensing | |

Power dissipation: | ≤1000W | ≤1500W |

Power Output: | 100W | 200W |

Laser Type: | Fibre | |

Maximum Pulse Energy: | 1.5mJ | 1.5mJ |

Pulse Frequency Range: | 1-3000kHz(Gradient adjustable) | 1-3000kHz(Gradient adjustable) |

Pulse Width: | 13-500ns tunable | 13-500ns tunable |

Output Power Instability: | <5% | |

Wavelength: | 1064 nm | |

Head Cable Length: | 3 m | 3 m |

Cooling: | Air cooling | |

Focus Distance: | 160mm | 254mm |

Scanning mode: | Dual-axis; supports 9 scanning modes | |

Head Weight: | ≤0.9Kg | ≤0.9Kg |

Size W x H x D: | About 677mm*298mm*575mm | |

Entire Unit Weight: | About 38Kg | About 38Kg |

Packed weight: | About 50Kg | About 50Kg |

Operation Mode: | Handheld/Automation | |

Safety Class: | Level IV | |

Application:

Use Cases:

FAQ:

Q1: WHAT IS THE MAXIMUM CLEANING AREA PER HOUR?

A1: UP TO 500 CM²/S DEPENDING ON THE MATERIAL AND LASER POWER.

Q2: WHAT IS THE PRECISION LEVEL OF THE LASER SPOT SIZE?

A2: THE SPOT SIZE CAN BE ADJUSTED FROM 0.1 MM TO 5 MM FOR DIFFERENT APPLICATIONS.

Q3: CAN IT CLEAN MULTI-LAYERED CONTAMINANTS?

A3: YES, IT CAN REMOVE MULTIPLE LAYERS INCLUDING RUST, PAINT, AND OXIDE IN ONE PASS.

Q4: WHAT IS THE MAXIMUM WORKING DISTANCE FROM THE LASER HEAD TO THE MATERIAL?

A4: TYPICALLY 10–50 CM, DEPENDING ON THE MODEL AND FOCUSING LENS.

Q5: DOES IT WORK ON BOTH METALS AND NON-METALS?

A5: YES, IT IS SUITABLE FOR METALS (STEEL, ALUMINUM) AND NON-METALS (PLASTICS, CERAMICS).