High Quality Portable Laser Rust Removal Machine

Exceptional Mobility

As the name implies, portability is a major selling point. These machines are designed to be lightweight and compact, allowing operators to carry them easily to different work sites. Some models come with handles or are small enough to be held in one hand, enabling on - the - go rust removal. Whether it's a small workshop, a construction site, or an outdoor project, the portable laser rust removal machine can be transported with ease, eliminating the need to move heavy metal components to a fixed cleaning station.

High Precision

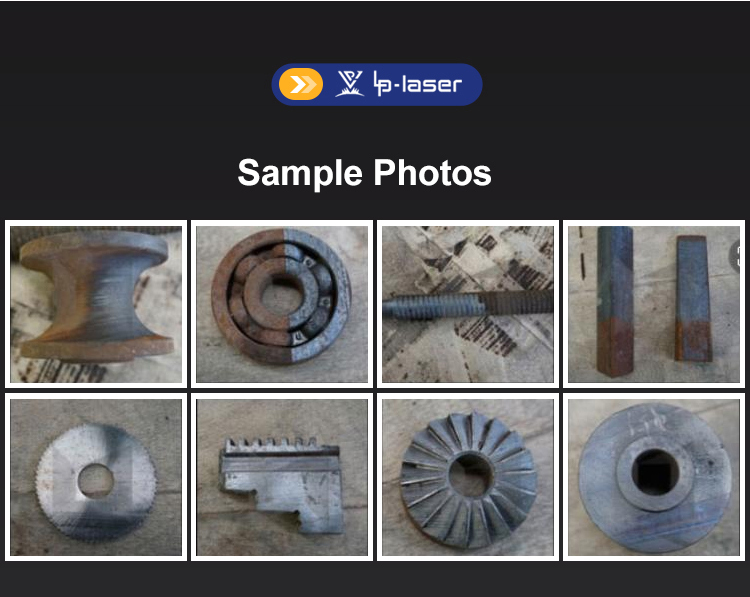

The laser beam can be focused to a very fine point, enabling extremely precise rust removal. This is crucial when dealing with delicate metal parts or components where only specific areas need to be cleaned. For example, in the restoration of antique metal artifacts or the maintenance of precision machinery, the ability to target rust precisely without affecting the surrounding areas is of utmost importance. The machine's precision ensures that the integrity and functionality of the metal parts are maintained.

Non - Contact and Non - Abrasive Cleaning

Unlike traditional rust - removal methods that rely on abrasive tools such as sandpaper, wire brushes, or chemical solvents, the portable laser rust removal machine cleans surfaces without any physical contact. This non - abrasive approach eliminates the risk of scratching, denting, or deforming the metal surface. It is particularly suitable for metals with soft textures, thin - walled components, or those with high - precision surface requirements. By using a non - contact method, the original surface finish and material properties of the metal are preserved.

Environmentally Friendly

In an era of increasing environmental awareness, the portable laser rust removal machine stands out as an eco - conscious choice. It does not require the use of water, harsh chemicals, or abrasive materials, which are commonly used in traditional rust - removal processes. Traditional methods often produce wastewater contaminated with chemicals or generate dust pollution, both of which can have negative impacts on the environment and human health. The laser cleaning process, on the other hand, produces only a small amount of vaporized rust and some particulate matter. These by - products can be easily managed with proper ventilation and filtration systems, making it a sustainable option for rust removal.

High Efficiency

Equipped with powerful laser sources, these portable machines can clean rust - covered surfaces at an impressive speed. The high - energy laser beam acts quickly on the rust, accelerating the removal process. Compared to manual rust - removal methods that involve labor - intensive scrubbing or scraping, or traditional mechanical cleaners that may require disassembly of parts, the portable laser rust removal machine can cover large areas in a relatively short time. In industrial settings, where time is of the essence, this high efficiency significantly reduces the time spent on rust - removal tasks, leading to increased productivity.

Cost - Effective in the Long Run

Although the initial investment in a portable laser rust removal machine may seem relatively high compared to some basic traditional rust - removal tools, it offers long - term cost savings. There is no need to constantly purchase and replace consumables such as abrasive media, chemical solvents, or brushes. The machine is also energy - efficient, consuming less power compared to some traditional cleaning equipment. Additionally, by minimizing the risk of damaging the metal workpiece during cleaning, it reduces the cost of rework and replacement. In the long term, these factors contribute to a lower overall cost of operation.

Portable Laser Rust Removal Machine Introduction

In the field of surface treatment, the portable laser rust removal machine has emerged as a game - changing tool, offering a host of advantages over traditional rust - removal methods. This device is designed to be a convenient, efficient, and eco - friendly solution for removing rust from various metal surfaces.

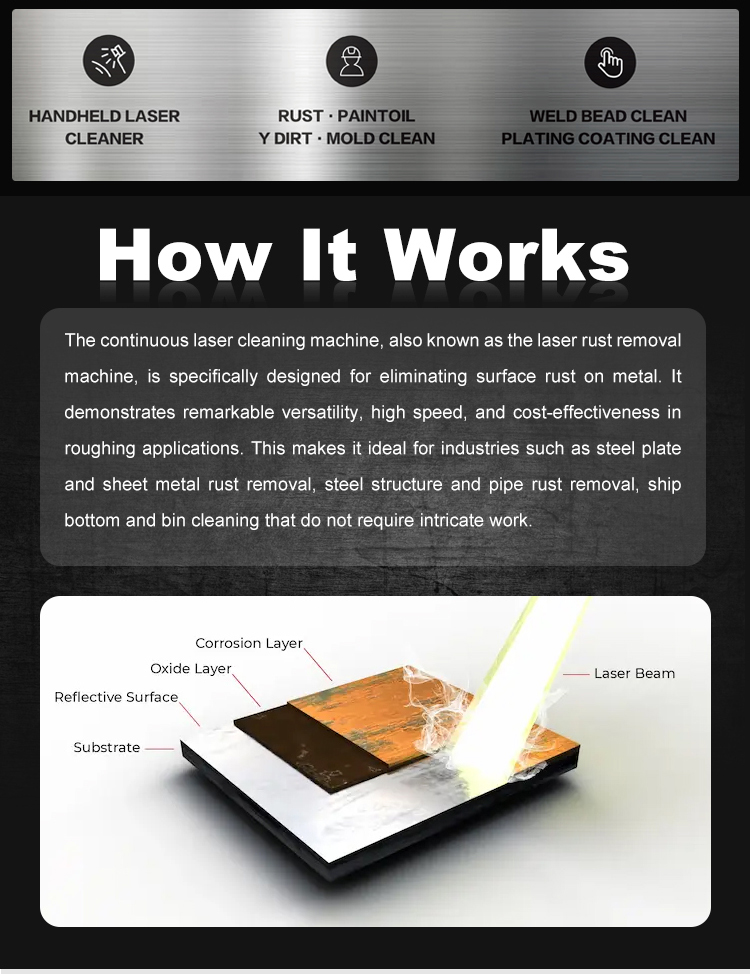

Working Principle

The portable laser rust removal machine operates on a straightforward yet highly effective principle. It emits a concentrated laser beam. When this beam strikes the rust - covered metal surface, the rust absorbs the laser energy. The absorbed energy causes the rust to heat up rapidly. As a result, the rust either vaporizes or is ablated into small particles. This process occurs without any physical contact with the metal substrate, ensuring that the underlying metal remains undamaged. The high - energy laser beam can precisely target the rust, even in hard - to - reach areas, making it a versatile solution for rust removal.

| Laser power | 1500W/2000W/3000W |

| Laser Wavelength | 1080±10nm |

Output power Instability | <2% |

| Output Power Tunability | 10-100% |

| Cooling Way | Water-cooling |

| Cooling medium | Purified water, distilled water, high-purity water |

| Working Environment Requirements | 10℃~40℃, humidity<70% |

| Voltage | 220V/380V/Customized |

| Cleaning Width | 40mm |

| Auxiliary Gas | Nitrogen/ArgonIn hand |

| Welding Mode | Straight line, fish scale, spot |

Q1: What's the typical ROI period?

A: 6-18 months (fastest when replacing high-labor methods like manual grinding).

Q2: How to calculate cost per m²?

A: (Energy + labor + maintenance) ÷ area cleaned = typically $0.20-$1.50/m².

Q3: What are consumable costs?

A: Negligible - 90%+ lower than sandblasting media (only protective windows/lenses).

Q4: How does equipment lifespan affect cost?

A: 10+ year lifespans make annualized capital cost often <$10k for mid-range systems.

Q5: What financing options exist?

A: Lease-to-own (3-5 years), rentals, or pay-per-use models from most manufacturers.