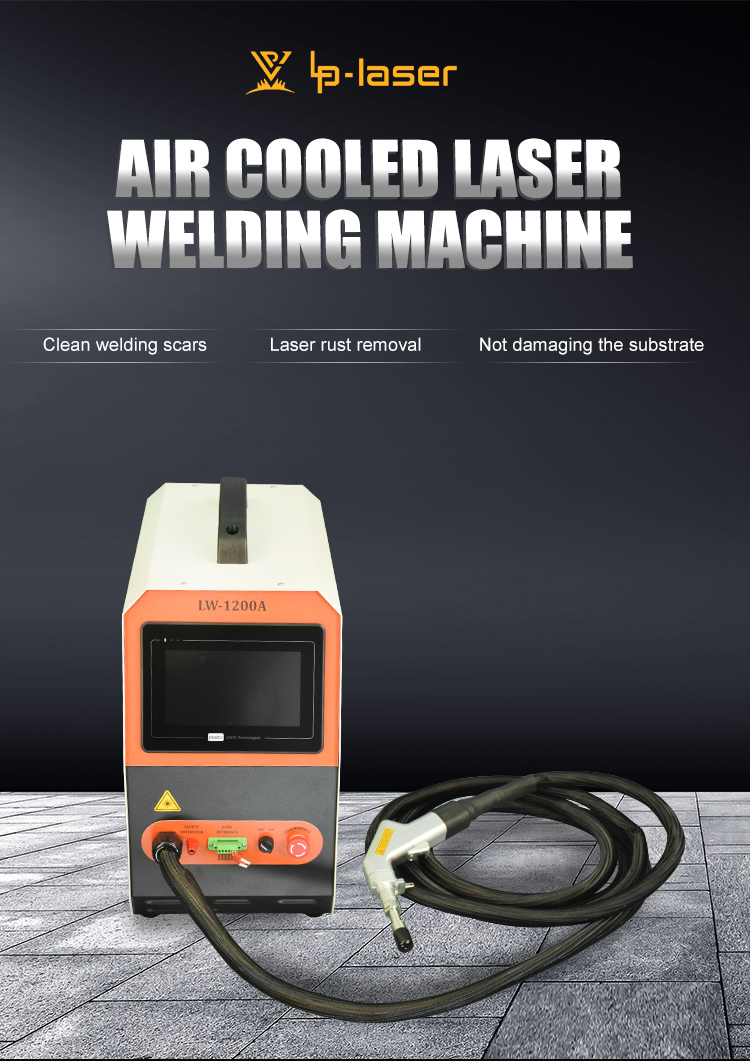

High Quality Air Cooled Laser Welding Machine

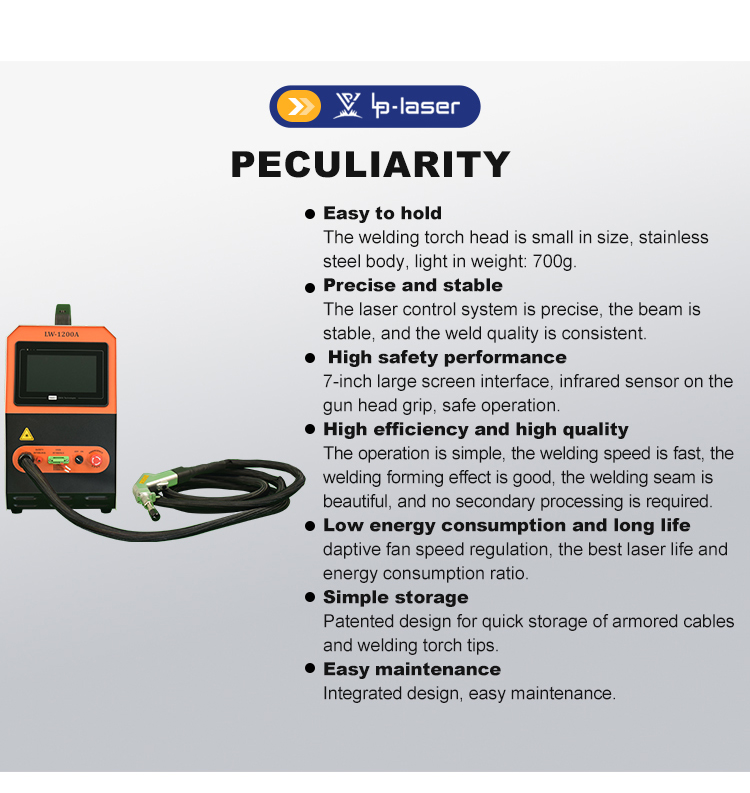

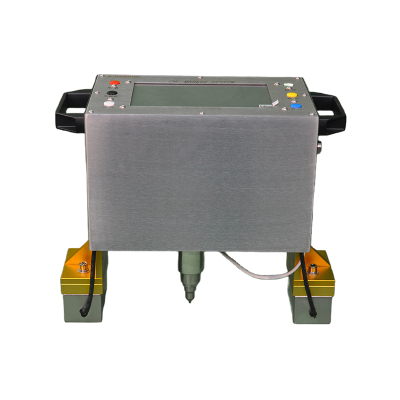

Compact and Portable Design

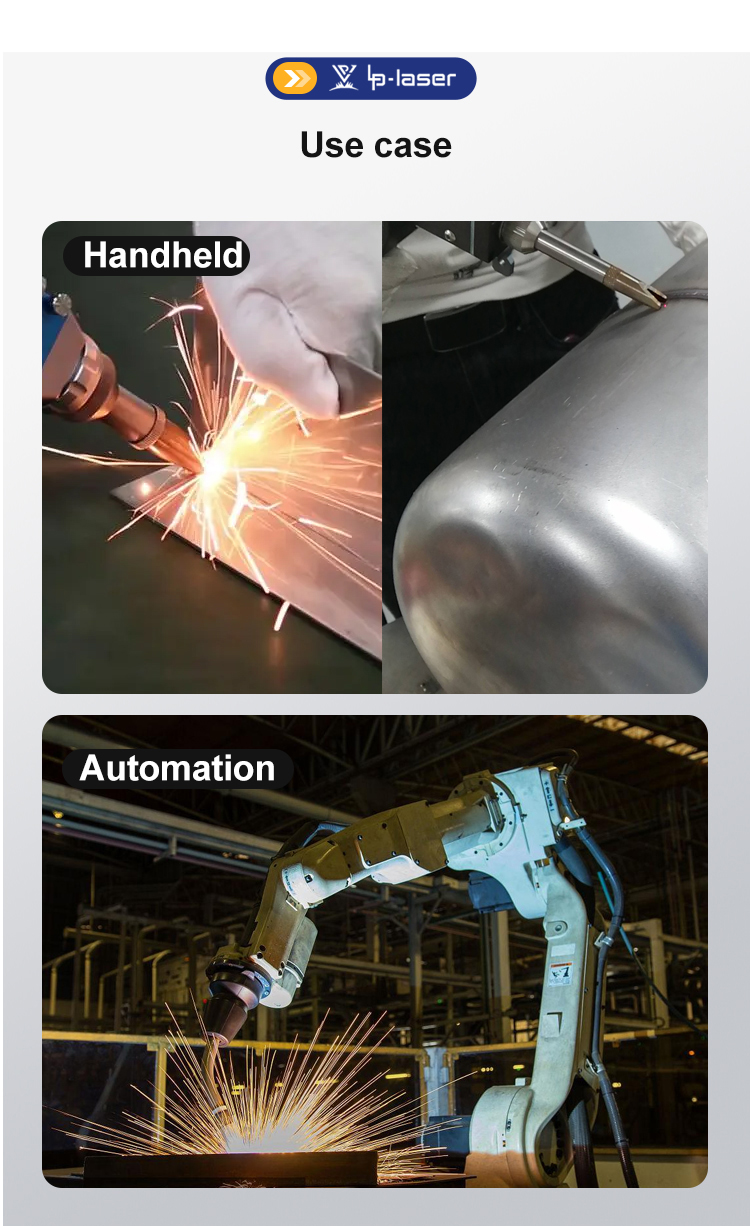

Air cooled laser welding machines are typically more compact compared to their water - cooled counterparts. Without the need for a bulky water cooling system, they take up less floor space, making them ideal for small workshops or areas with limited space. Their lightweight construction also enhances portability, allowing for easy transportation between different work sites. Some models are even designed to be handheld, providing maximum flexibility for on - the - go welding tasks.

Low Maintenance Requirements

The air cooling system is relatively simple, which significantly reduces maintenance needs. There are no complex water circulation systems to worry about, such as water pumps, pipes, or heat exchangers that may require regular cleaning, flushing, or replacement. This simplicity not only saves time but also reduces the overall cost of ownership, as there are fewer components that can potentially malfunction.

High Heat Tolerance

These machines are engineered to withstand high heat conditions during operation. The efficient air cooling design enables them to dissipate heat effectively, preventing overheating and ensuring reliable performance even in demanding industrial environments. This high heat tolerance contributes to the machine's durability and long - lasting operation, reducing the need for frequent replacements.

Cost - Effective Operation

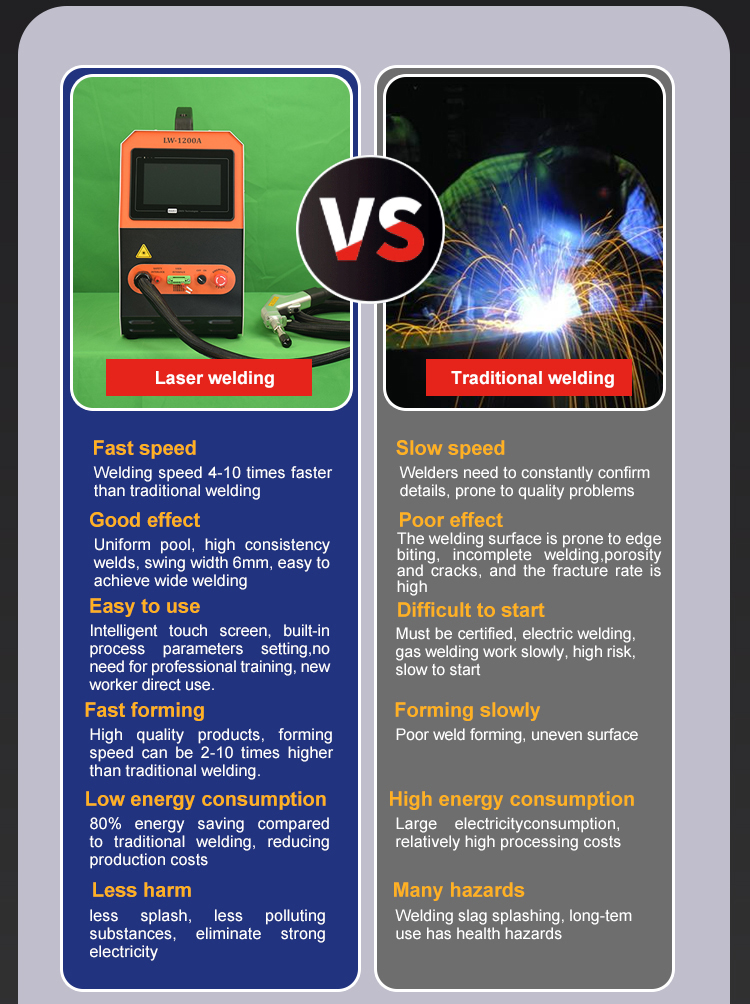

Air cooled laser welding machines offer cost savings in multiple ways. Firstly, they consume less energy compared to water - cooled machines since there is no need to power a water cooling system. Secondly, the reduced maintenance requirements translate into lower maintenance costs over time. Additionally, their compact size and portability can lead to savings in terms of space utilization and transportation costs, making them an attractive option for businesses looking to optimize their resources.

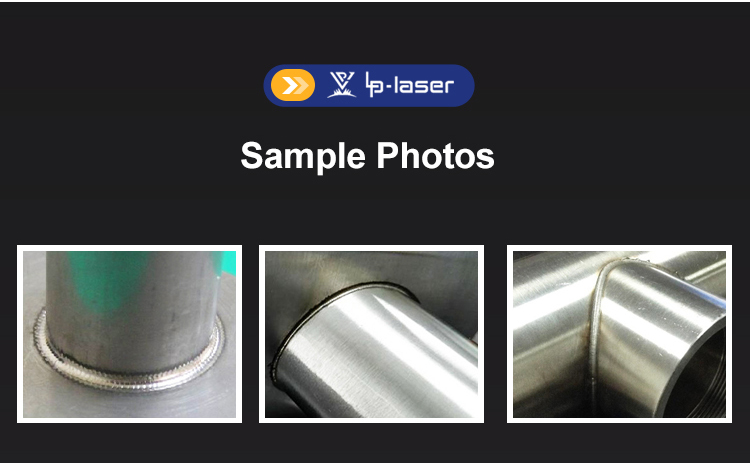

Precise Welding Performance

Despite their compact and cost - effective nature, air cooled laser welding machines deliver high - precision welding results. The laser beam can be precisely focused to a small spot, allowing for intricate and accurate welds. This is crucial for applications where fine details and high - quality joints are required, such as in the electronics, jewelry, and medical device industries. The machines can produce strong and reliable welds with minimal heat - affected zones, preserving the integrity of the surrounding materials.

Air Cooled Laser Welding Machine Introduction

In the dynamic field of metal joining, air cooled laser welding machines have emerged as a game - changing solution, offering a unique blend of efficiency, convenience, and cost - effectiveness.

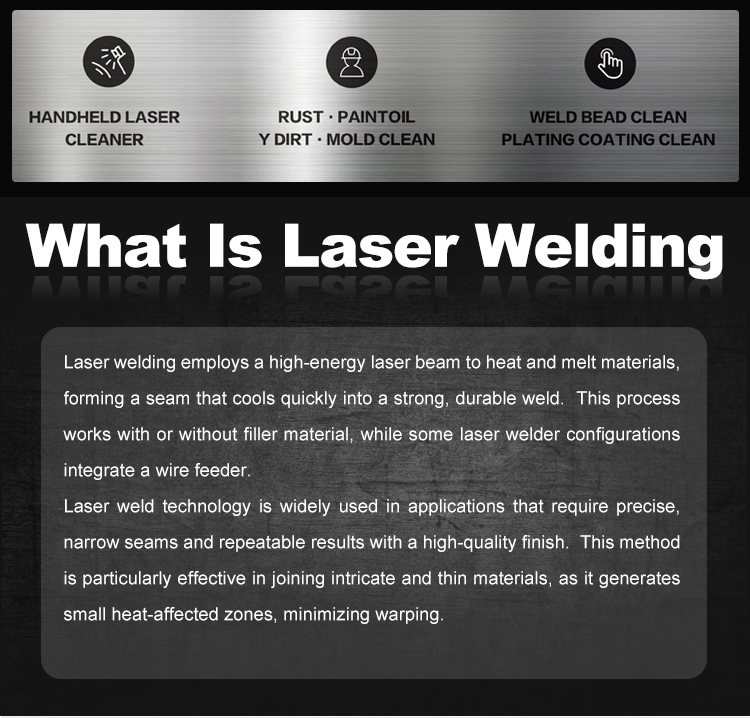

Working Principle

These machines operate by emitting a high - energy laser beam. The beam is focused onto the metal surfaces to be joined. As the laser energy is absorbed by the metals, it rapidly heats the materials, causing them to melt and fuse together. The air cooling mechanism, as the name implies, uses ambient air to dissipate the heat generated during the laser operation. This keeps the laser source and other critical components at an optimal temperature, ensuring stable and continuous performance.

| Average Output Power | 800W/1200W |

Operation Mode | CW/Modulate |

| Max Modulation Frequency | 5KHz |

| Output Power Stability | ±3% |

| Polarization | Random |

| Delivery Cable Length | 10M |

| Power Supply | 1 PH 220V five wire connect |

| Cooling | Air cooling |

| Output laser wavelength | 1080*10MM |

| Machine Weight | 26Kg |

Q1: How effective for weld prep?

A: 3x faster than grinding with perfect Sa 2.5 surface profile for welding.

Q2: Can clean aerospace components?

A: Yes - turbine blades cleaned at 0.05mm precision with 50-100W systems.

Q3: What about automotive molds?

A: 200W systems remove release agents in 30 mins vs. 4 hours manually.

Q4: Historical artifact suitability?

A: Ideal - removes corrosion while preserving original patina with adjustable parameters.

Q5: Rubber/plastic cleaning possible?

A: Limited - requires careful control to avoid melting; 355nm UV lasers work best.