High Performance Fiber Laser Welding Machine

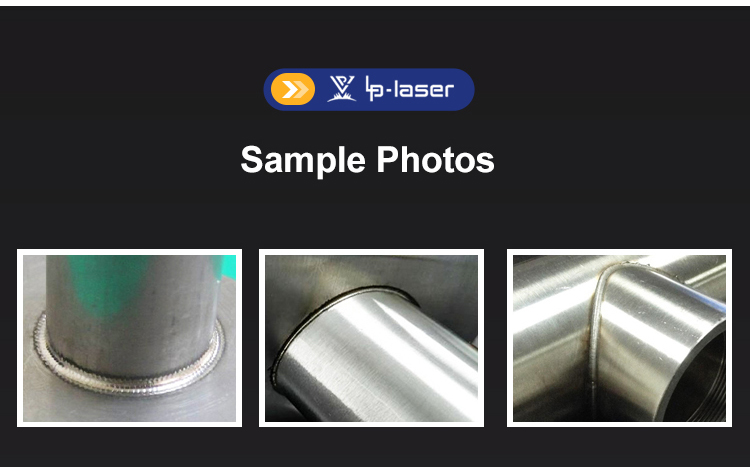

High Precision Welding

The fiber - delivered laser beam can be focused to an extremely small spot size, typically in the range of a few tens of microns. This enables highly precise welding, making it ideal for applications where fine details and tight tolerances are required. Whether it's joining tiny electronic components or creating intricate patterns in jewelry, fiber laser welding machines can achieve seamless and accurate welds with minimal heat - affected zones.

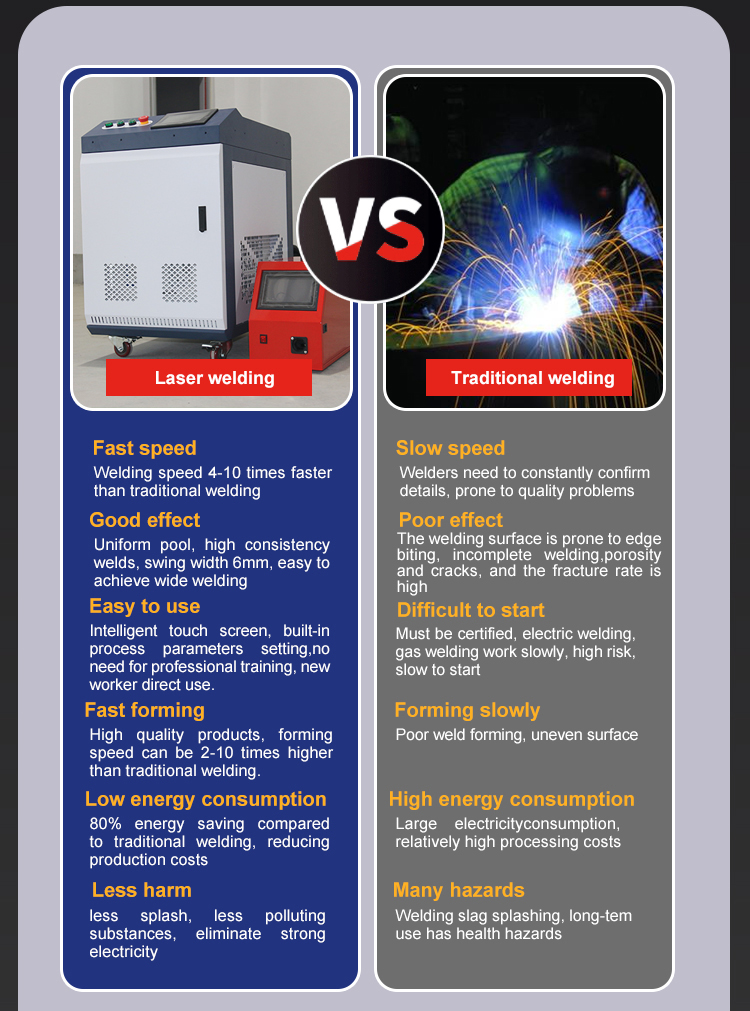

High - Speed and High - Efficiency

Compared to traditional welding methods such as arc welding or gas - tungsten arc welding (GTAW), fiber laser welding is significantly faster. The high - energy density of the laser beam allows for rapid melting of the metal, reducing the overall welding time. In industrial production lines, this increased speed can lead to a substantial boost in productivity. For example, in automotive manufacturing, fiber laser welding machines can quickly weld multiple components, contributing to faster assembly times.

Versatile Material Compatibility

Fiber laser welding machines can be used to weld a wide variety of metals and alloys. This includes common metals like stainless steel, carbon steel, aluminum, and copper, as well as more exotic materials such as titanium and nickel - based alloys. The ability to weld dissimilar metals is also a major advantage. For instance, in the aerospace industry, fiber laser welding can be used to join different metal components to create lightweight yet strong structures.

Low Heat - Affected Zone

The laser beam's energy is highly concentrated at the weld site, resulting in a minimal heat - affected zone (HAZ). This is crucial as it reduces the risk of distortion, warping, or changes in the material's mechanical properties in the surrounding areas. In applications where the integrity of the base material is critical, such as in the manufacturing of medical devices or high - precision machinery, the small HAZ of fiber laser welding ensures that the final product meets strict quality standards.

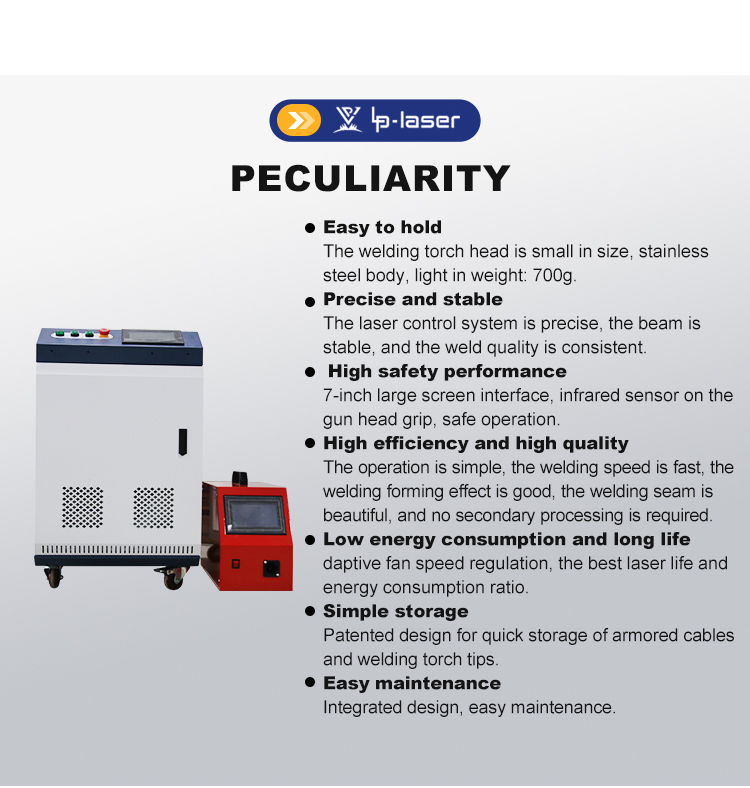

Compact and Energy - Efficient Design

Fiber laser sources are generally more compact than traditional laser systems, taking up less floor space in a workshop or factory. Additionally, they are highly energy - efficient. The diode - pumped operation of fiber lasers consumes less power compared to some other laser types, which not only reduces operating costs but also makes them a more environmentally friendly choice.

Ease of Automation

These machines are well - suited for automation. They can be integrated into robotic systems or automated production lines, allowing for repetitive and consistent welding tasks. Automated fiber laser welding systems can be programmed to follow complex welding paths, increasing production speed and reducing the need for manual labor. This is particularly beneficial in large - scale manufacturing operations where high - volume production is required.

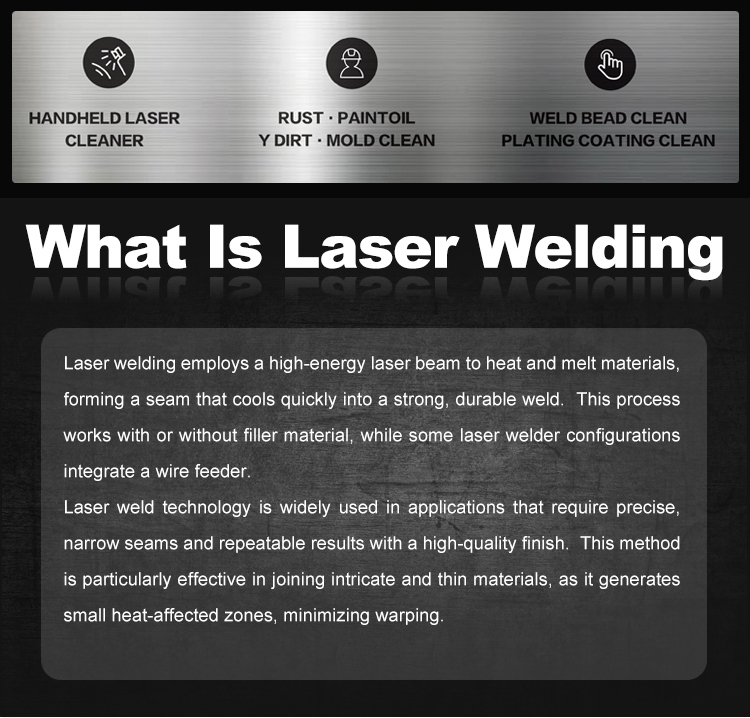

Fiber Laser Welding Machine Introduction

In the ever - evolving landscape of metal joining technologies, fiber laser welding machines have emerged as a leading solution, offering unparalleled precision, efficiency, and versatility.

Working Principle

Fiber laser welding machines operate by generating a high - energy laser beam within a fiber optic cable. The laser source, often a diode - pumped fiber laser, emits photons that are guided through the fiber. As the beam exits the fiber, it is focused onto the metal surfaces to be welded. The intense heat from the laser rapidly raises the temperature of the metal, causing it to melt and fuse together. The process can be controlled precisely, allowing for accurate and consistent welds. Some machines use a pulsed laser beam for specific applications, while others offer continuous wave operation for high - speed welding.

| Laser Type | Fiber Laser |

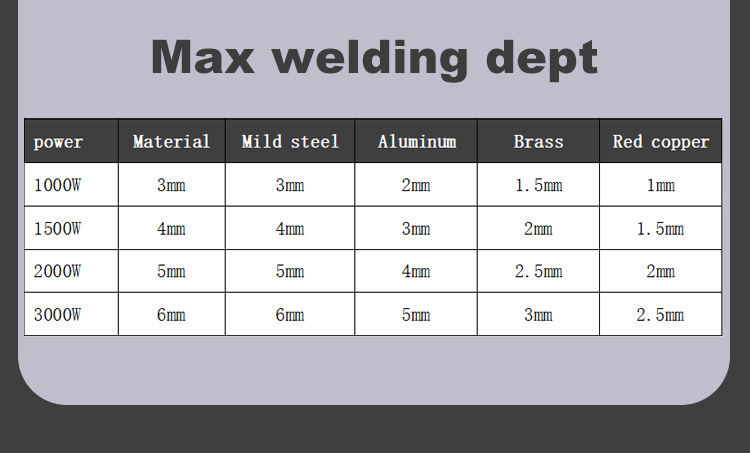

Laser Power | 1500W/2000W/3000W |

| Laser Wavelength | 1080±10nm |

| Output power Instability | <2% |

| Output Power Tunability | 10-100% |

| Cooling Way | Water-cooling |

| Cooling medium | Purified water, distilled water, high-purity water |

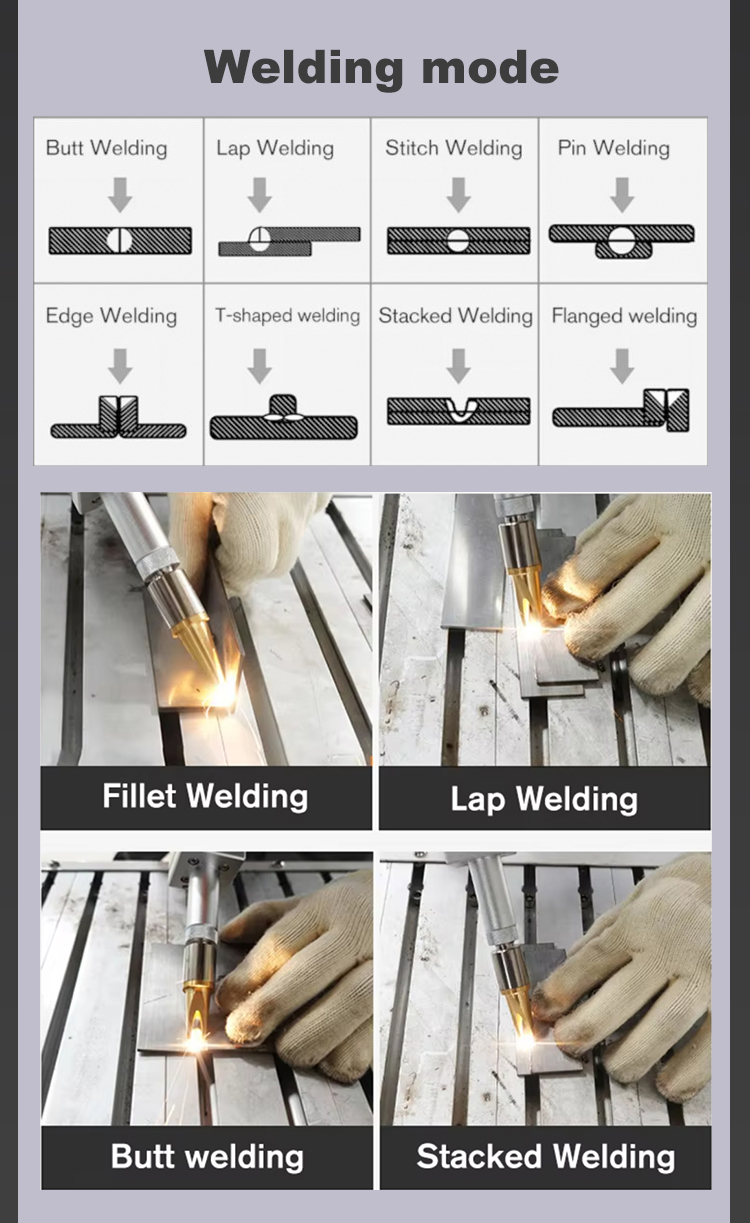

| Welding Mode | Straight line, fish scale, spot |

| Cleaning Width | 40mm |

| Voltage | 220V/380V/Customized |

| Working Environment Requirements | 10℃~40℃, humidity<70% |

Q1: How to clean gold-plated items?

A: Use short pulses (ns) at low fluence (1-2J/cm²) to selectively remove tarnish.

Q2: Can strip coatings from glass?

A: Yes - UV lasers (355nm) with precise control to prevent microcracks.

Q3: How to clean pipe interiors?

A: Endoscopic attachments with 45°/90° mirrors reach internal surfaces.

Q4: Best approach for composites?

A: Low power (50W) + high scan speeds (1m/s+) with parameter tuning.

Q5: Can create surface patterns?

A: Yes - programmable galvo systems generate micro-textures for adhesion promotion