High Performance Handheld Laser Welding Machine

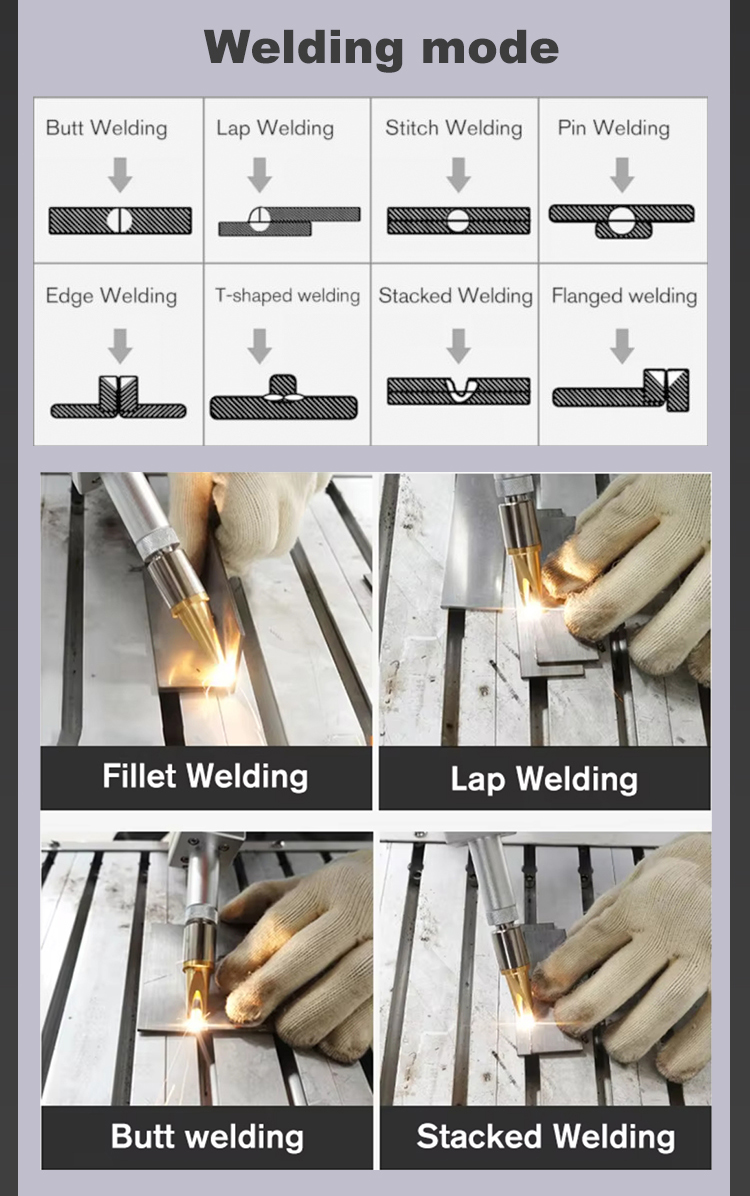

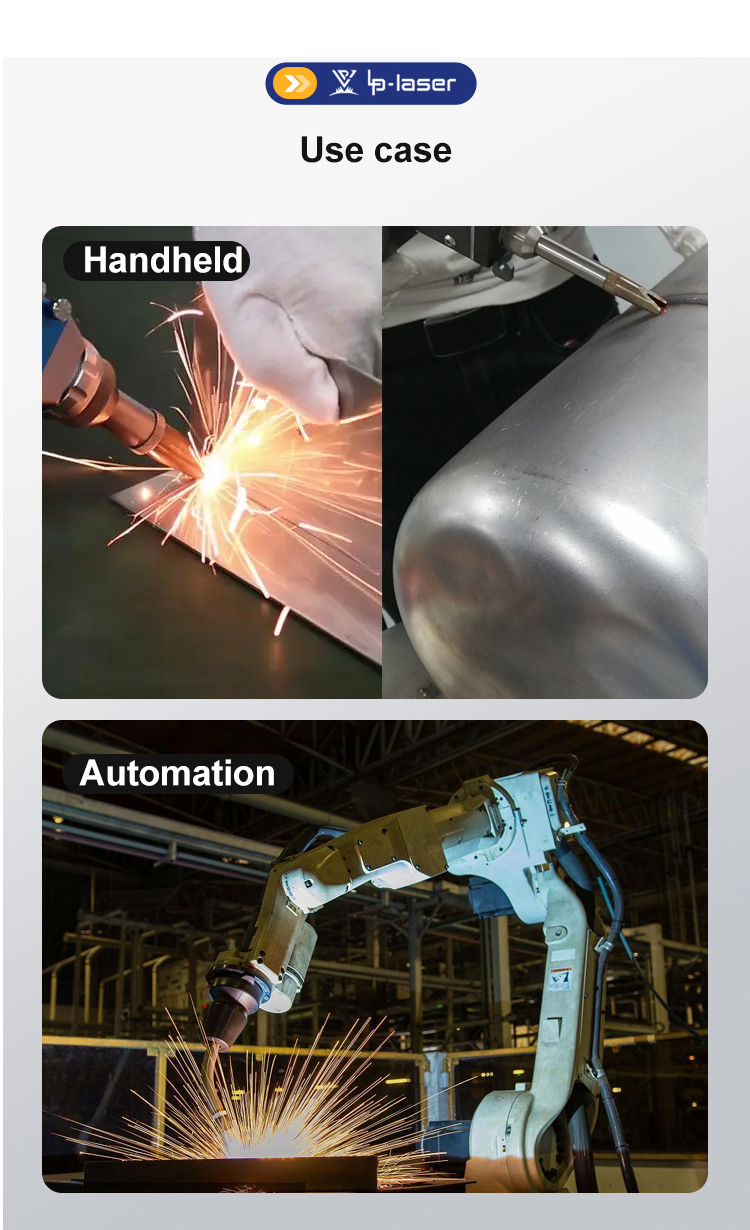

Exceptional Flexibility

One of the most significant advantages of the handheld laser welding machine is its flexibility. Unlike traditional fixed - position laser welding systems, the handheld design allows operators to reach difficult - to - access areas and weld complex geometries with ease. Whether it's welding around corners, in tight spaces, or on large - scale structures, the portable nature of the machine enables on - site welding, eliminating the need to transport heavy workpieces to a dedicated welding station. This flexibility is particularly beneficial for industries such as construction, automotive repair, and custom metal fabrication, where the ability to weld in various locations is crucial.

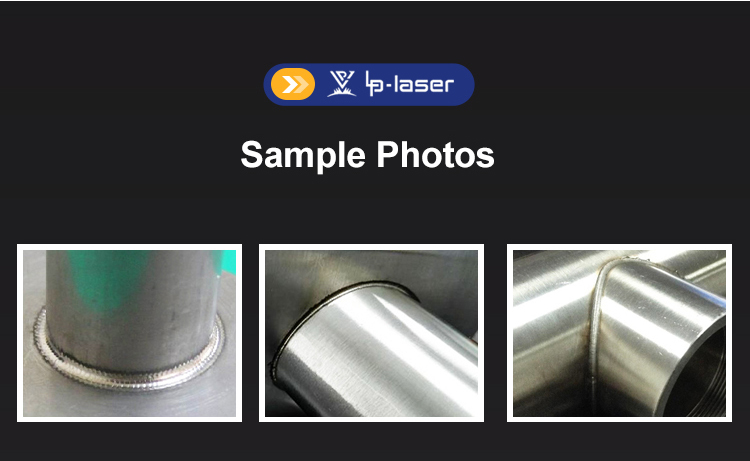

High Precision Welding

The laser beam emitted by the handheld welding machine can be focused to an extremely small spot size, typically in the range of a few tens of microns. This high level of precision enables operators to create fine and accurate welds, making it ideal for applications that require delicate work, such as jewelry making, electronics manufacturing, and medical device production. The small focused spot ensures that the heat input is concentrated precisely on the welding area, minimizing the heat - affected zone (HAZ) and reducing the risk of distortion or damage to the surrounding material. This results in high - quality welds with excellent joint integrity and minimal post - welding finishing requirements.

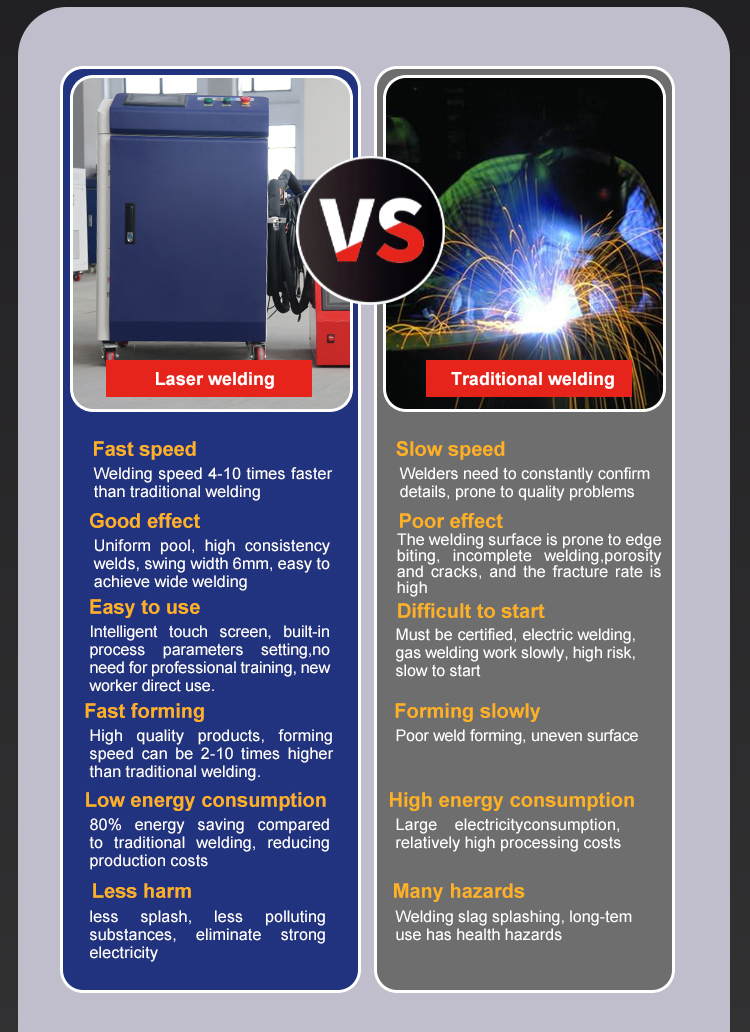

Fast Welding Speed

Compared to many traditional welding methods, such as arc welding or gas - tungsten arc welding (GTAW), handheld laser welding offers significantly faster welding speeds. The high - energy density of the laser beam allows for rapid melting of the metal, enabling operators to cover more area in less time. In industrial production settings, this increased speed can lead to a substantial boost in productivity. For example, in a metal fabrication shop, the use of a handheld laser welding machine can reduce the time required to weld multiple components, allowing for faster turnaround times and increased output.

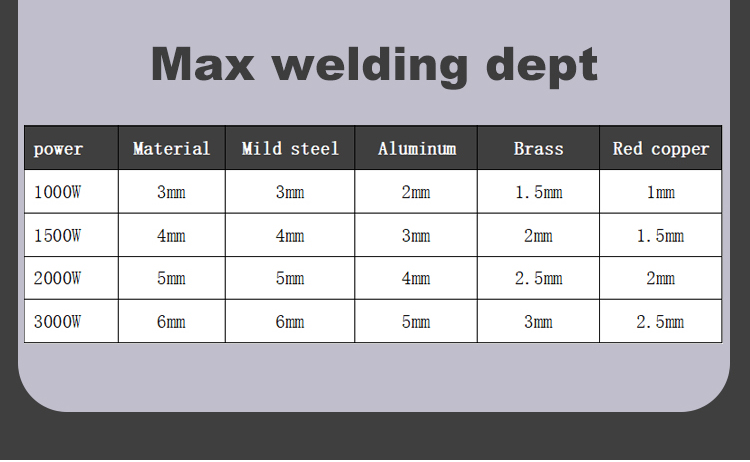

Versatile Material Compatibility

Handheld laser welding machines are capable of welding a wide variety of metal materials. They can effectively join common metals like stainless steel, carbon steel, aluminum, and copper, as well as more exotic alloys such as titanium and nickel - based alloys. Additionally, the machine can often handle the welding of dissimilar metals, which is a challenging task with traditional welding techniques. This versatility makes it a valuable tool for industries with diverse material requirements, such as aerospace, where different metals are used in the construction of aircraft components to balance strength, weight, and other performance characteristics.

Low Heat - Affected Zone

As mentioned earlier, the concentrated nature of the laser beam results in a small heat - affected zone. This is a crucial advantage, especially when working with materials that are sensitive to heat or when maintaining the integrity of the base metal is essential. In applications such as the manufacturing of precision machinery, where dimensional accuracy is critical, the minimal HAZ of handheld laser welding ensures that the surrounding areas of the weld remain unaffected, reducing the need for post - welding machining or corrective measures. It also helps in preserving the mechanical properties of the metal, such as hardness and toughness, in the vicinity of the weld.

Cost - Effective Operation

Despite its advanced technology, the handheld laser welding machine offers cost - effective operation in the long run. It has relatively low energy consumption compared to some traditional welding equipment. Additionally, the machine requires fewer consumables, as there is no need for continuous wire feeding or large amounts of shielding gas in many cases. The reduced need for post - welding finishing, such as grinding and polishing to smooth out rough welds, also saves time and labor costs. Moreover, the machine's durability and reliability contribute to lower maintenance costs over its lifespan, making it an attractive option for businesses looking to optimize their welding processes and reduce overall production costs.

User - Friendly Operation

Most handheld laser welding machines are designed with user - friendliness in mind. They typically feature intuitive control panels or interfaces that allow operators to easily adjust parameters such as laser power, pulse duration, and welding speed according to the specific requirements of the job. Even those with limited welding experience can quickly learn to use the machine effectively after a short training period. The lightweight and ergonomic design of the handheld welding gun ensures comfortable handling during extended use, reducing operator fatigue. Some models also come with built - in safety features, such as protective shields and interlocks, to prevent accidental exposure to the laser beam, further enhancing the machine's usability and safety.

Handheld Laser Welding Machine Introduction

In the ever - evolving world of metalworking and fabrication, the handheld laser welding machine has emerged as a revolutionary tool. This innovative device combines the precision and power of laser technology with the flexibility of a handheld tool, offering a wide range of benefits for various industries.

Working Principle

The handheld laser welding machine operates based on the principle of using a high - energy laser beam to melt and fuse metal surfaces together. Inside the machine, a laser source, often a fiber laser, generates a concentrated beam of light. This beam is then transmitted through an optical fiber to the handheld welding gun. When the operator activates the gun, the laser beam is directed onto the metal parts to be welded.

Upon contact with the metal, the high - energy laser beam is rapidly absorbed by the material. The energy causes the metal atoms to vibrate vigorously, generating heat. This heat quickly raises the temperature of the metal to its melting point, creating a molten pool. As the laser beam moves along the joint, the molten metal flows together, and when it cools and solidifies, a strong and durable weld is formed. Some advanced models also have the option to control the laser pulse, allowing for more precise control over the welding process, especially for delicate materials or complex joint designs.

| Average Output Power | 1500W,2000W,3000W |

| Laser wavelength | 1070NM |

| The fiber length is standard | 10M Supports a maximum of 15M |

| Working mode | Continuous/modulation |

| Welding speed | 0~120 mm/s |

| Cooling machine | Industrial thermostatic water tank |

| Operating ambient temperature range | 15~35 ℃ |

| Working environment humidity range | < 70% no condensation |

Q1: What makes your laser cleaning technology superior?

A: Our patented adaptive pulse control automatically adjusts parameters for different materials, ensuring perfect cleaning without substrate damage - a feature competitors lack.

Q2: How does your wavelength flexibility help my application?

A: We offer 1064nm, 532nm, and 355nm options in one system, allowing optimal cleaning of everything from steel to sensitive electronics.

Q3: Why is your pulse duration range better?

A: With 2-200ns adjustable pulses, we handle delicate restoration and industrial-scale cleaning equally well - others force you to choose.

Q4: How does your spot size adjustment outperform others?

A: Our dynamic beam shaping provides 0.1-10mm spot sizes without lens changes, saving 30% operation time.

Q5: What safety innovations do you offer?

A: The industry's only AI-powered reflection detection system automatically shuts down if unsafe conditions occur.