High Performance Lightweld Laser Welder

Compact and Portable Design

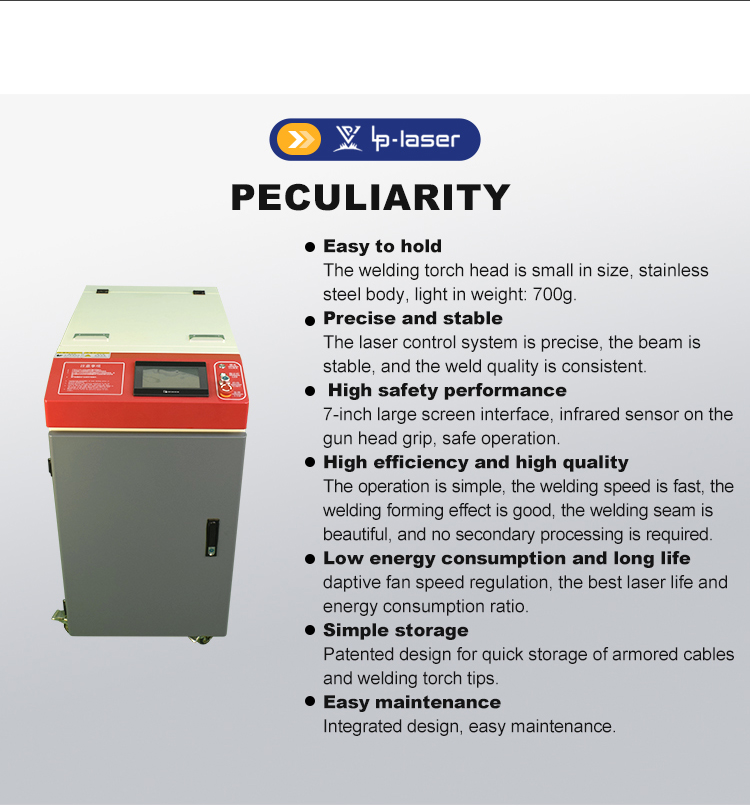

One of the most striking features of the Lightweld Laser Welder is its compact and portable nature. Unlike traditional, bulky laser welding systems that are often fixed in a dedicated workstation, the Lightweld is designed to be highly mobile. Its lightweight construction and ergonomic handheld welding gun make it easy for operators to carry and maneuver, enabling them to reach difficult - to - access areas and weld in various locations. This portability is a game - changer for industries such as on - site construction, automotive repair, and custom metal fabrication, where the ability to perform welding tasks on the go is crucial.

High - Precision Welding

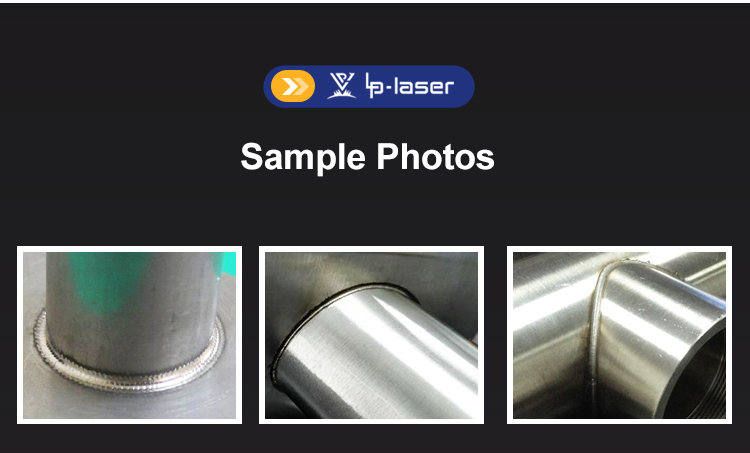

The Lightweld Laser Welder is renowned for its exceptional precision. The laser beam can be focused to an extremely small spot size, typically in the range of a few tens of microns. This high level of precision allows operators to create fine and accurate welds, making it an ideal choice for applications that demand delicate work. In industries such as jewelry making, electronics manufacturing, and medical device production, where the smallest details matter, the Lightweld can achieve seamless and high - quality welds with minimal heat - affected zones (HAZs). The small focused spot ensures that the heat input is concentrated precisely on the welding area, reducing the risk of distortion or damage to the surrounding material.

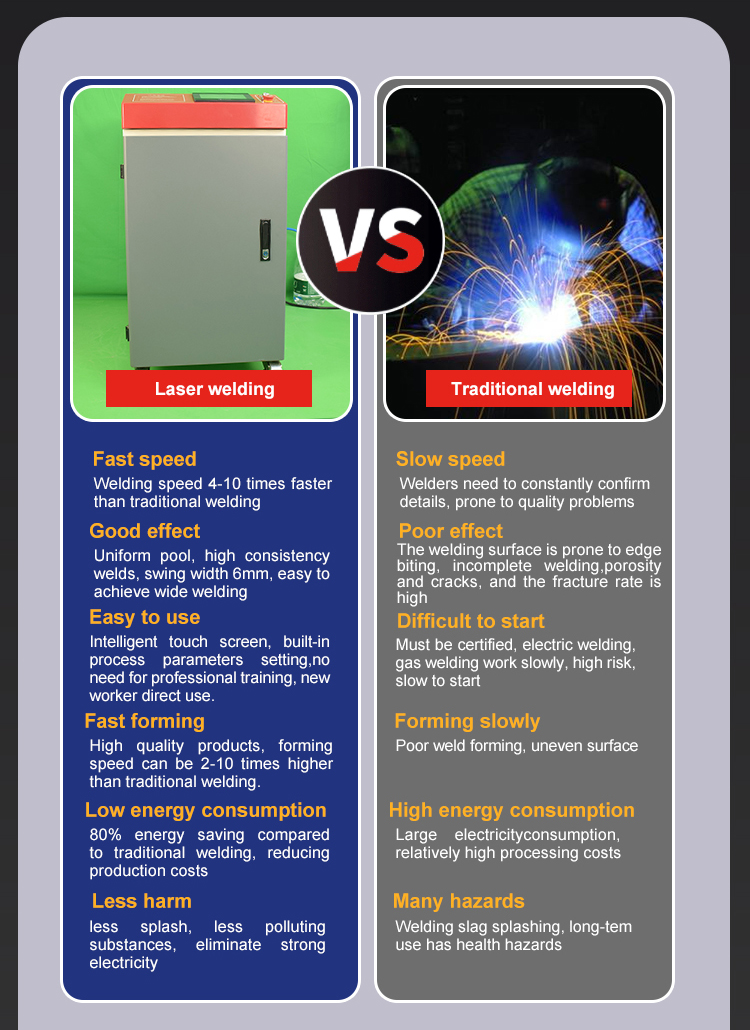

Fast Welding Speed

Compared to many traditional welding methods, such as arc welding or gas - tungsten arc welding (GTAW), the Lightweld Laser Welder offers significantly faster welding speeds. The high - energy density of the laser beam enables rapid melting of the metal, allowing operators to cover more area in less time. In industrial production settings, this increased speed can lead to a substantial boost in productivity. For example, in a metal fabrication shop, the use of the Lightweld can reduce the time required to weld multiple components, resulting in faster turnaround times and increased output. This speed advantage not only saves time but also contributes to cost - savings in high - volume production environments.

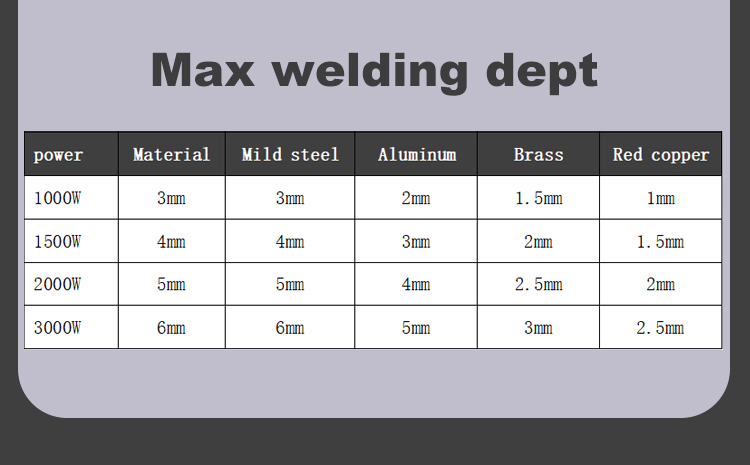

Versatile Material Compatibility

The Lightweld Laser Welder demonstrates remarkable versatility in terms of material compatibility. It can effectively weld a wide range of metal materials, including common metals like stainless steel, carbon steel, aluminum, and copper, as well as more exotic alloys such as titanium and nickel - based alloys. Additionally, it has the capability to handle the welding of dissimilar metals, a challenging task with traditional welding techniques. This versatility makes it a valuable asset for industries with diverse material requirements, such as the aerospace industry, where different metals are used in the construction of aircraft components to balance strength, weight, and other performance characteristics.

Low Heat - Affected Zone

The concentrated nature of the laser beam in the Lightweld Laser Welder results in a minimal heat - affected zone. This is a critical advantage, particularly when working with materials that are sensitive to heat or when maintaining the integrity of the base metal is of utmost importance. In applications such as the manufacturing of precision machinery, where dimensional accuracy is crucial, the small HAZ of the Lightweld ensures that the surrounding areas of the weld remain unaffected. This reduces the need for post - welding machining or corrective measures and helps to preserve the mechanical properties of the metal, such as hardness and toughness, in the vicinity of the weld.

Cost - Effective Operation

Despite its advanced technology and high - performance capabilities, the Lightweld Laser Welder offers cost - effective operation in the long run. It has relatively low energy consumption compared to some traditional welding equipment, contributing to reduced utility bills. Additionally, the machine requires fewer consumables. In many cases, there is no need for continuous wire feeding or large amounts of shielding gas, further cutting down on operational costs. The reduced need for post - welding finishing, such as grinding and polishing to smooth out rough welds, also saves time and labor costs. Moreover, the machine's durability and reliability contribute to lower maintenance costs over its lifespan, making it an attractive option for businesses looking to optimize their welding processes and reduce overall production costs.

User - Friendly Operation

Designed with user - friendliness in mind, most Lightweld Laser Welder models feature intuitive control panels or interfaces. These allow operators to easily adjust parameters such as laser power, pulse duration, and welding speed according to the specific requirements of the job. Even those with limited welding experience can quickly learn to use the machine effectively after a short training period. The lightweight and ergonomic design of the handheld welding gun ensures comfortable handling during extended use, reducing operator fatigue. Some models also come equipped with built - in safety features, such as protective shields and interlocks, to prevent accidental exposure to the laser beam, further enhancing the machine's usability and safety.

Lightweld Laser Welder Introduction

In the dynamic realm of laser welding technology, the Lightweld Laser Welder has emerged as a game - changing solution, revolutionizing the way various industries approach metal joining processes. Engineered with cutting - edge features and innovative design, this welder combines power, precision, and versatility to meet the diverse needs of modern manufacturing and fabrication.

Working Principle

At its core, the Lightweld Laser Welder operates on the fundamental principle of laser - induced melting and fusion. It harnesses the energy of a high - intensity laser beam, typically generated by a fiber - optic - based laser source. This laser beam is transmitted through a flexible optical fiber to the handheld welding gun, which serves as the operator - controlled interface.

When the operator activates the welding gun, the laser beam is directed onto the metal surfaces to be joined. The highly concentrated energy of the laser beam is rapidly absorbed by the metal, causing the atoms within the material to vibrate vigorously. This intense vibration generates heat, which quickly raises the temperature of the metal to its melting point. As a result, a molten pool is formed at the weld site.

As the laser beam moves along the joint, the molten metal flows together, and upon cooling and solidification, a strong and durable weld is created. Some advanced models of the Lightweld Laser Welder offer the option to control the laser pulse. This feature allows for even more precise control over the welding process, especially when dealing with delicate materials or complex joint geometries. By adjusting the pulse parameters such as duration, frequency, and energy, operators can fine - tune the heat input and achieve optimal welding results.

| Laser Type | Fiber Laser |

| Laser Power | 1500W/2000W/3000W |

| Laser Wavelength | 1080±10nm |

| Output power Instability | <2% |

| Output Power Tunability | 10-100% |

| Cooling Way | Water-cooling |

| Cooling medium | Purified water, distilled water, high-purity water |

| Welding Mode | Straight line, fish scale, spot |

| Cleaning Width | 40mm |

| Voltage | 220V/380V/Customized |

| Working Environment Requirements | 10℃~40℃, humidity<70% |

Q: Are you trading company or manufacturer ?

A: Both trading company and manufacturer.So we can offer you a pretty competitve price,with high quality.

Q: What’s the package?

A: We have 3 layers package. For the outside, we pack with wood craft case. In the middle, the machine is covered by foam,to protect the machine from shaking.For the inside layer, the machine is covered by thickening plastic bag for waterproof.

Q: Will the package damaged during transportation?

A: Our team considerate all the damage factors and try to ensure the package can be arrived in good condition, and our shipping agent have full experienced in safe transportation.So please don’t worry.If the damages caused by transportion,please contact us asap,we will offer you the best solution.

Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. Instruduction or video can beoffered to teach how to install and run the machine. 95% customers can learn by themselves.

Q: How can I do if the machine goes wrong?

A: Once the machine goes wrong, please contact us asap and do not try fix the machine by yourself or someone else. We will response within 24 hours as quick as we can and our techic staff will offer the solution for you.