Metal Laser Cleaning Machine

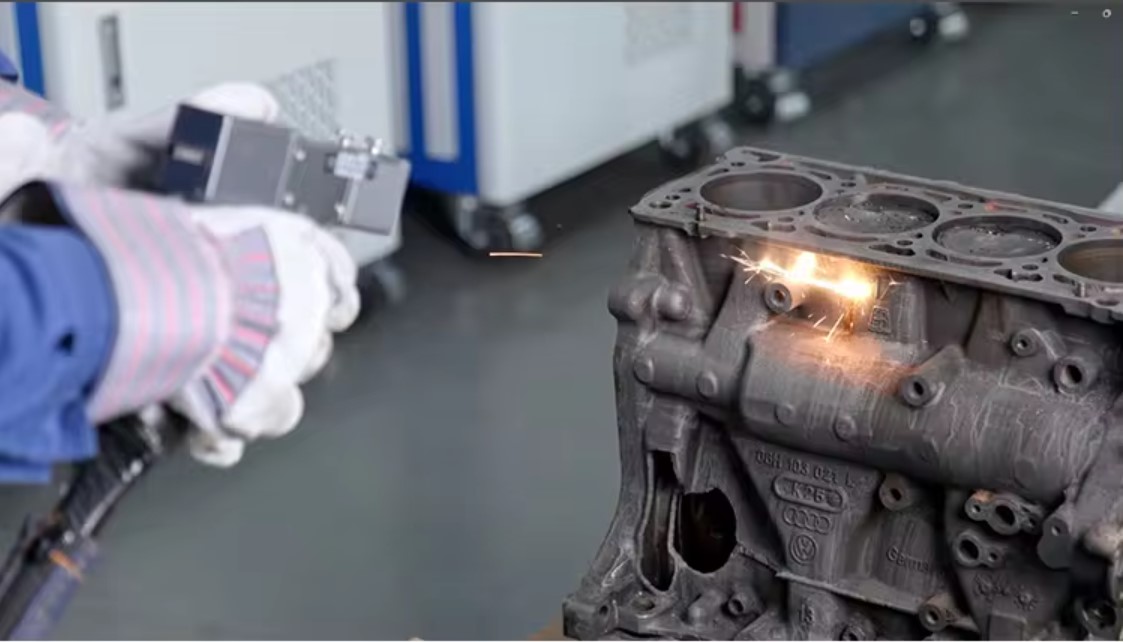

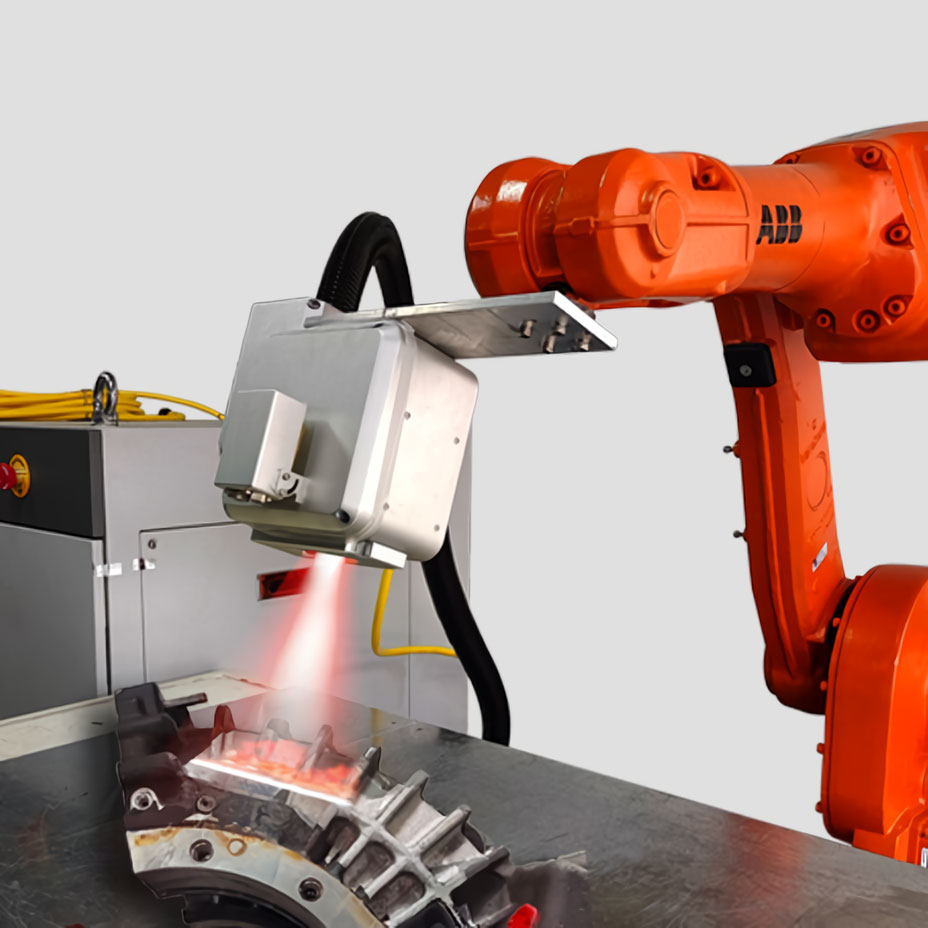

1.Laser Source: Metal laser cleaning machine is equipped with a high-powered laser source, typically a fiber laser or a pulsed solid-state laser. The laser beam is focused onto the surface of the metal to be cleaned.

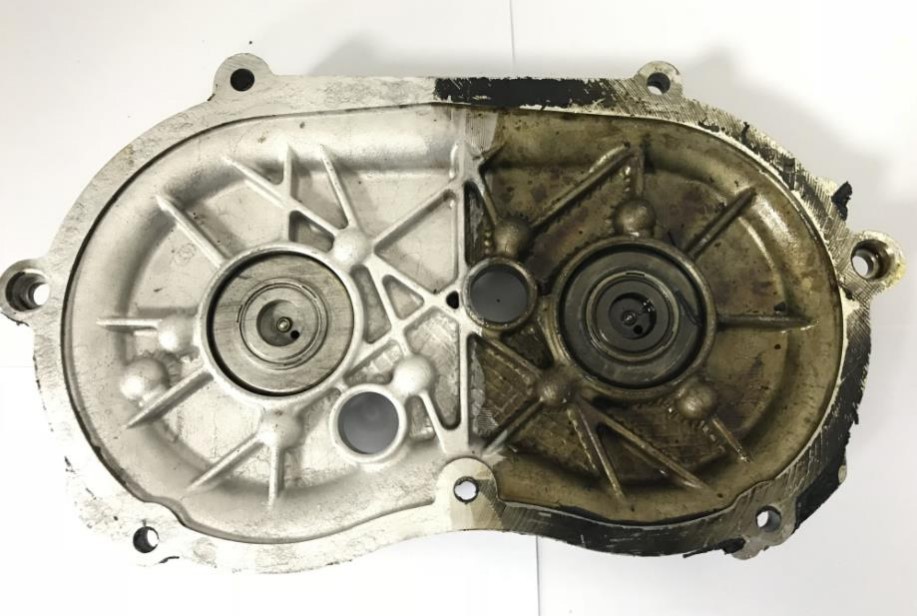

2.Precision: Laser cleaning is highly precise, allowing for selective removal of contaminants without affecting the underlying metal. This is particularly useful for delicate or intricate parts.

3.Non-Abrasive: Unlike traditional methods like sandblasting or grinding, laser cleaning does not abrade the surface, which means there is no risk of altering the dimensions or shape of the metal part.

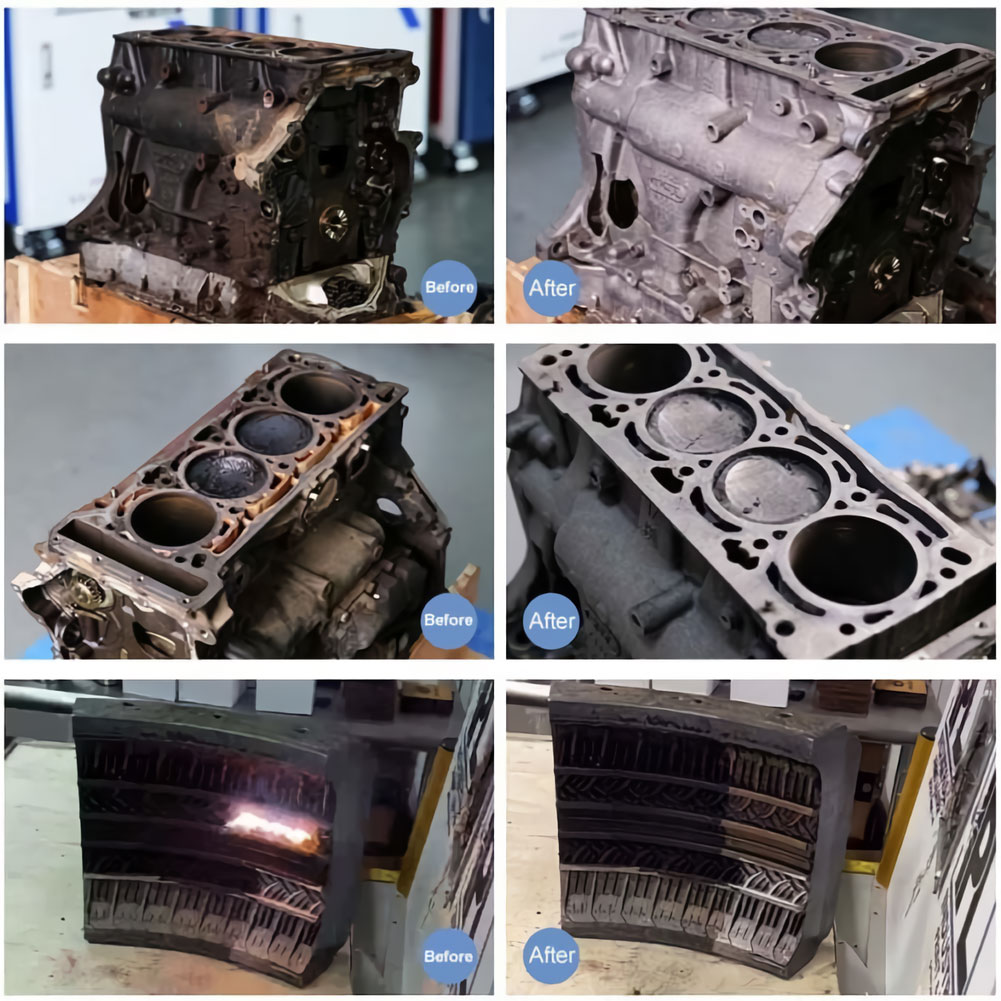

4.Versatility: Laser cleaning can be used on a wide range of metals and alloys, including steel, aluminum, copper, and more. It can remove various types of contaminants, from rust and scale to paint and grease.

How Metal Laser Cleaning Machine Works?

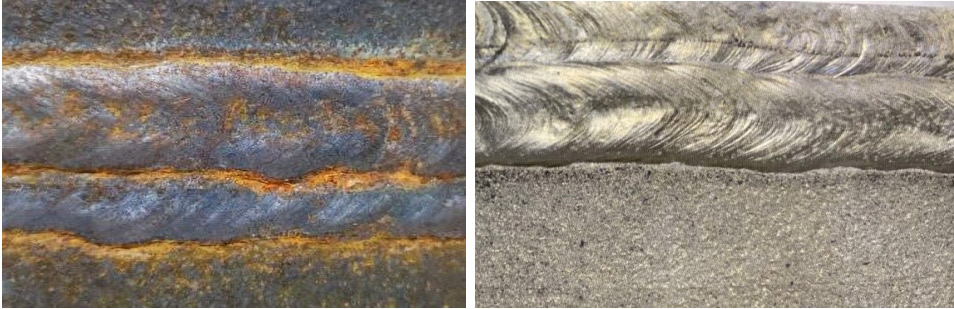

Metal laser cleaning machines use laser rays for cleaning, not only for mould cleaning, but also for the cleaning of various workpieces during processing. The success of laser cleaning as an alternative to conventional cleaning methods is due to the many advantages of this process. On the one hand, it does not require cleaning agents or the disposal of residual waste, and therefore has very low operating costs. On the other hand, it is very precise and protects the surface. Above all, the use of laser rays achieves excellent cleaning results. All kinds of oxides, dust particles and especially impurities formed by polymer lubricants, which are very difficult to remove, can be evaporated by the laser in a matter of seconds. The laser-cleaned surfaces are ideally suited for further processing, such as laser welding.

Product Parameter:

Model: | HLC-P100W | HLC-P200W |

Operational Voltage: | 220V±10%、50/60Hz Customisable:110V、50Hz alternating current | |

Temperature: | 5℃ ~40℃ | |

Humidity: | 30-85% Non-Condensing | |

Power dissipation: | ≤1000W | ≤1500W |

Power Output: | 100W | 200W |

Laser Type: | Fibre | |

Maximum Pulse Energy: | 1.5mJ | 1.5mJ |

Pulse Frequency Range: | 1-3000kHz(Gradient adjustable) | 1-3000kHz(Gradient adjustable) |

Pulse Width: | 13-500ns (tunable) | 13-500ns (tunable) |

Output Power Instability: | <5% | |

Wavelength: | 1064 nm | |

Head Cable Length: | 3 m | 3 m |

Cooling: | Air cooling | |

Focus Distance: | 160mm | 254mm |

Scanning mode: | Dual-axis; supports 9 scanning modes | |

Head Weight: | ≤0.9Kg | ≤0.9Kg |

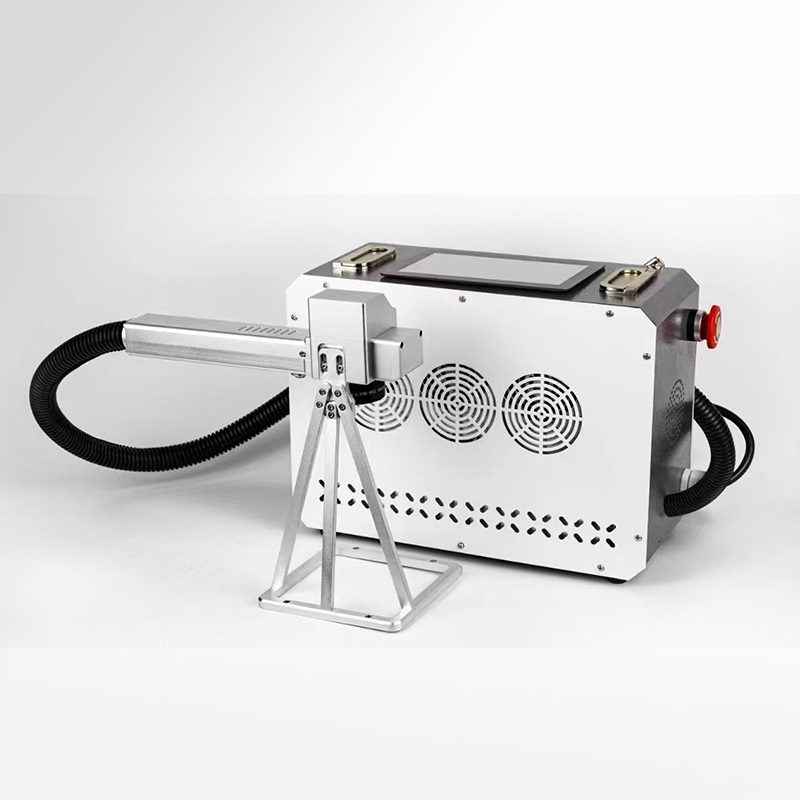

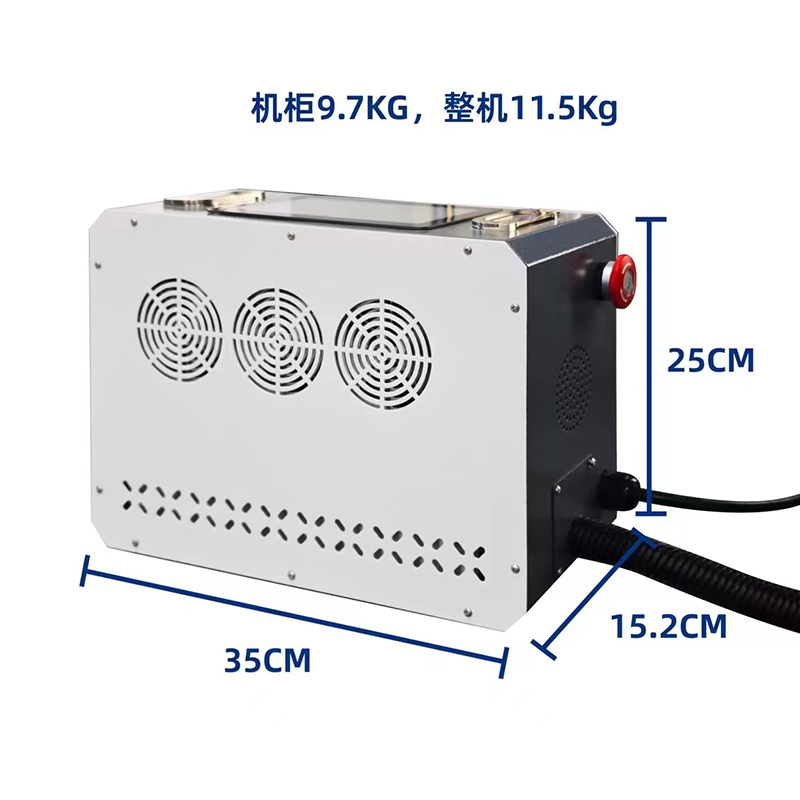

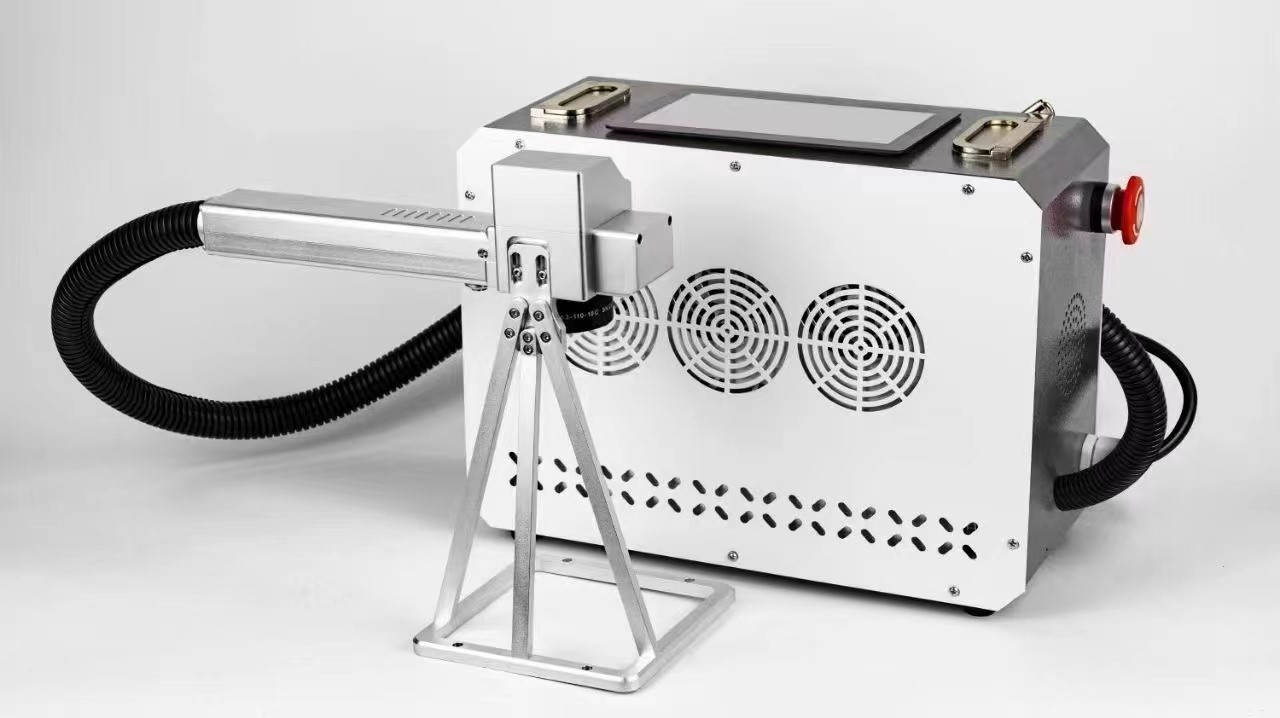

Size W x H x D: | About 350mm*152mm*250mm | |

Entire Unit Weight: | About 12Kg | About 18Kg |

Packed weight: | About 20Kg | About 26Kg |

Operation Mode: | Handheld/Automation | |

Safety Class: | Level IV | |

Sample Photos:

Application:

Use Cases:

FAQ:

Q1: How is your training better?

A: VR simulators let operators master techniques risk-free before handling real equipment.

Q2: What about remote support?

A: Augmented reality troubleshooting lets our experts see what you see in real-time.

Q3: How fast are your response times?

A: 24/7 live support with 94% of issues resolved remotely in under 15 minutes.

Q4: Do you offer application testing?

A: Free sample cleaning service - send us materials and we'll demonstrate optimal settings.

Q5: What training materials come included?

A: Interactive manuals with 300+ video tutorials searchable by material/application.