Advanced Fiber Laser Cleaning Machine

1. Superior Cleaning Performance

Non-contact, non-abrasive process preserves material integrity

Removes rust, paint, oxides, oil, coatings with micron-level precision

Adjustable power (200W-1000W+) for different material thicknesses

2. Unmatched Efficiency & Cost Savings

3-5X faster than sandblasting/chemical methods

Zero consumables - no media, chemicals or abrasive materials needed

Low maintenance design with 100,000+ hours laser source lifespan

3. Eco-Friendly & Safe Solution

No toxic chemicals or hazardous waste - fully RoHS/CE compliant

No secondary pollution - protects operator health and environment

No substrate damage - perfect for delicate surfaces and artifacts

4. Smart & User-Friendly Operation

Lightweight & portable designs available (stationary/mobile units)

Intuitive interface with preset programs for common materials

Automated scanning options for large-area cleaning

5. Industrial-Grade Durability

IP54 protection for harsh workshop environments

Air/water-cooled options for continuous operation

Modular design for easy maintenance and part replacement

Product introduction

The Fiber Laser Cleaning Machine is a cutting-edge industrial tool used for precision cleaning of various surfaces. It employs advanced fiber laser technology to remove rust, paint, grease, oxide layers, and other contaminants without causing damage to the substrate material. This machine is highly versatile and can be applied in industries such as automotive, aerospace, marine, metalworking, and more. With features such as adjustable laser power, high cleaning efficiency, minimal maintenance requirements, and environmentally friendly operation (no chemicals or abrasive materials needed), the Fiber Laser Cleaning Machine is an ideal solution for achieving pristine and ready-to-coat surfaces in a cost-effective manner.

| Model: | HLC-P200W | HLC-P300W | HLC-P300W(water-cooling) |

| Operational Voltage: | 220V±10%、50/60Hz Customizable: 110V, 50Hz AC | ||

| Temperature: | 5℃~40℃ | ||

| Humidity: | 30-85% Non-Condensing | ||

| Power dissipation: | ≤1500W | ≤2000W | ≤4000W |

| Power Output: | 200W | 300W | 300W |

| Laser Type: | Optical fiber | ||

| Maximum Pulse Energy: | 1.5mJ/2mJ/5mJ | 1.5mJ/5mJ | 12.5mJ |

| Pulse Frequency Range: | 1-4000kHz(Gradient adjustable) | 1-4000kHz(Gradient adjustable) | 1-4000kHz(Gradient adjustable) |

| Pulse Width: | 2-500ns tunable | 2-500ns tunable | 2-500ns tunable |

| Output Power Instability: | <5% | ||

| Wavelength: | 1064 nm | ||

| Head Cable Length: | 5 m | 5 m | 5 m |

| Cooling: | Air cooling | water-cooling | |

| Focus Distance: | 210mm | 210mm | 210mm |

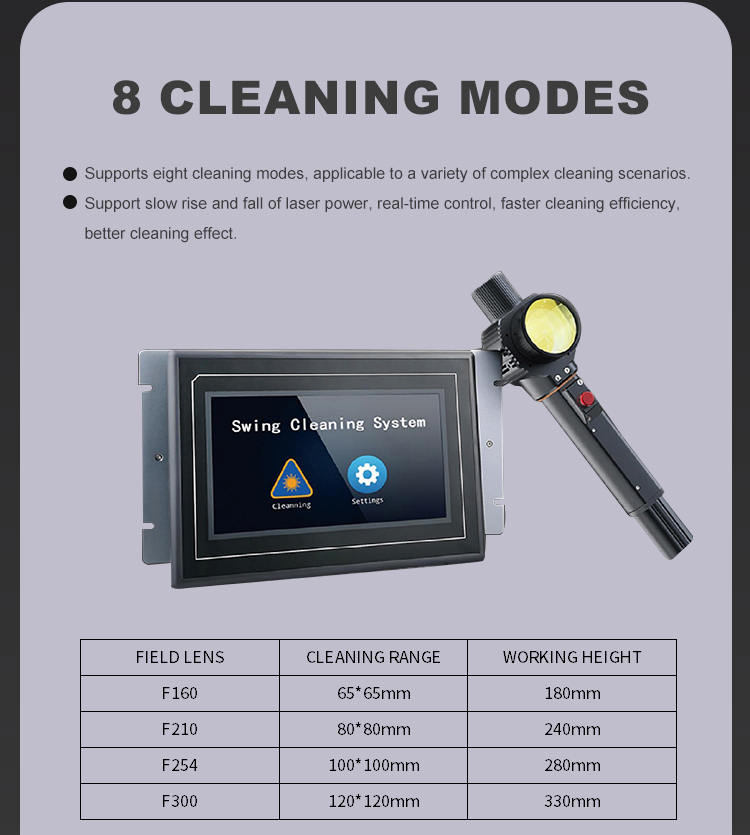

| Scanning mode: | Dual axis; Nine scanning modes are supported | ||

| Head Weight: | ≤0.9Kg | ≤1.25Kg | |

| Size W x H x D: | About629mm*341mm*734mm | About982mm*458mm*791mm | |

| Box Dimensions | About800mm*470mm*880mm | About1130mm*580mm*1050mm | |

| Entire Unit Weight: | About 52Kg | About 52Kg | About 135Kg |

| Packed weight: | About 67Kg | About 67Kg | About 165Kg |

| Operation Mode: | Handheld/Automation | Handheld/Automation | |

| Safety Class: | Level IV | Level IV | |

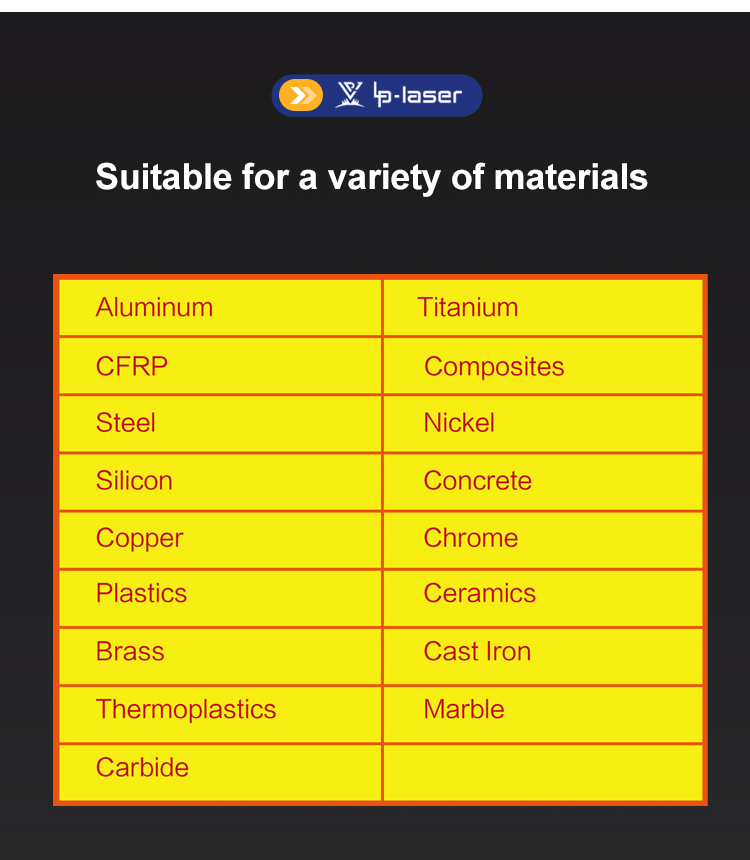

1. Materials Amenable to Laser Cleaning

Laser cleaners exhibit versatility in cleaning an extensive array of materials. These encompass metallic substances like aluminium, steel, copper, nickel, chromium, titanium, and cast iron; composite materials such as carbon - fibre reinforced plastics; semiconductor materials including silicon; non - metallic materials like plastics, thermoplastics, ceramics, marble, and carbide.

2. Effect on the Substrate during Cleaning

In the context of laser cleaning, the choice between pulse - mode and continuous - mode operation significantly influences the cleaning outcome and potential substrate damage. The pulse - mode laser cleaning is renowned for its ability to achieve a highly precise and detailed cleaning effect, while the continuous - mode is characterized by its relatively rapid cleaning speed. Generally, the pulse - mode inflicts less damage to the substrate compared to the continuous - mode. Through sophisticated algorithm optimization and precise control of cleaning parameters, including speed modulation, it is possible to approach a state where the cleaning process causes negligible damage to the underlying substrate material.

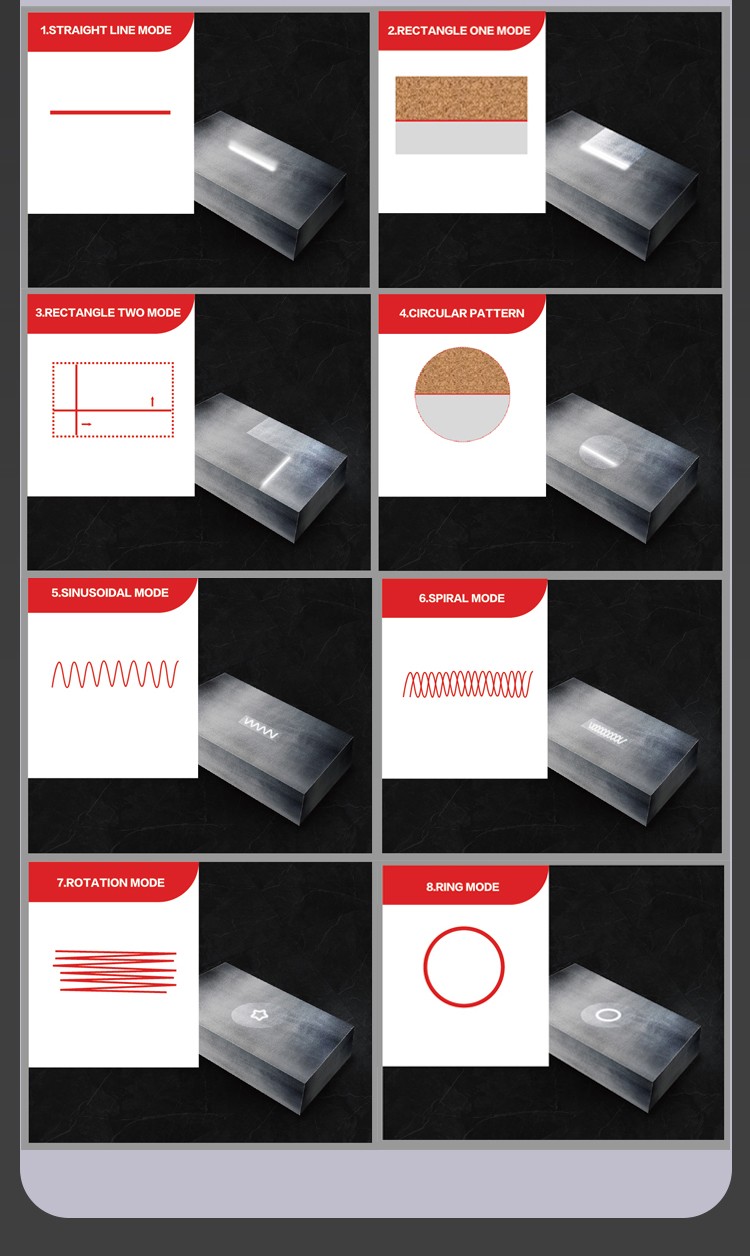

3. Supported Cleaning Modes

Our laser cleaning equipment is engineered to support a comprehensive set of nine cleaning modes. These modes include Linear, which enables linear - path cleaning; Rectangle I and Rectangle II, designed for rectangular - shaped cleaning areas with distinct configurations; Circle, facilitating circular cleaning operations; Sine, which follows a sinusoidal cleaning pattern; Spiral, for spiral - shaped cleaning trajectories; Free, offering unrestricted, user - defined cleaning paths; and the combination modes of Circle and Rotary, providing specialized cleaning options for circular and rotational applications.

4. Multilingual User Interfaces

Our product is equipped with an extensive selection of 16 language interfaces, catering to a global user base. The supported languages include Simplified Chinese, Traditional Chinese, English, Russian, Japanese, Spanish, German, Korean, French, among others. This multilingual functionality ensures seamless operation and user - friendliness across diverse linguistic regions.

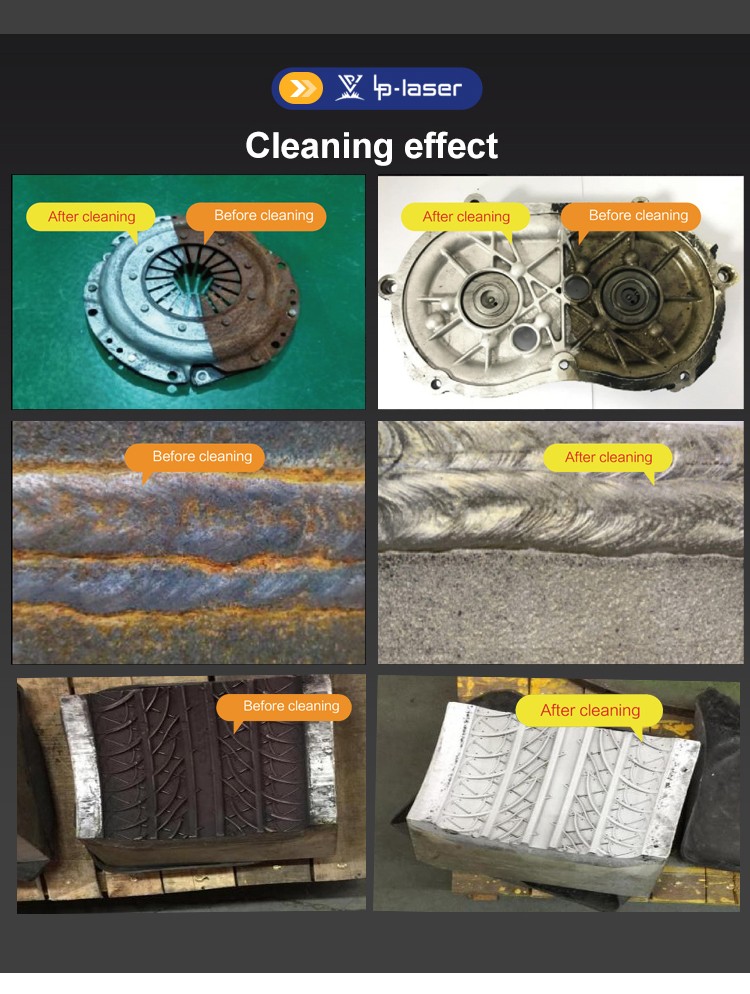

5. Product Applications

This laser cleaning machine is designed to address a broad spectrum of cleaning requirements. It is highly effective in removing a wide variety of contaminants, such as rust layers, paint coatings, oil residues, surface oxides, and adherent substances, even those at a microscopic level on stone statues. Additionally, it can efficiently eliminate rubber moulding residues. Furthermore, it plays a crucial role in the pre - treatment of welded or painted surfaces, ensuring optimal surface conditions for subsequent processes.