Efficient Metal Laser Cleaning Machine

1. High Precision and Selectivity

Metal laser cleaning machines offer unrivaled precision. The laser beam can be accurately focused on specific areas of the metal surface.

2.Non - Abrasive and Non - Contact

3.Environmentally Friendly

4.High Efficiency

5.Cost - Effective Long - Term

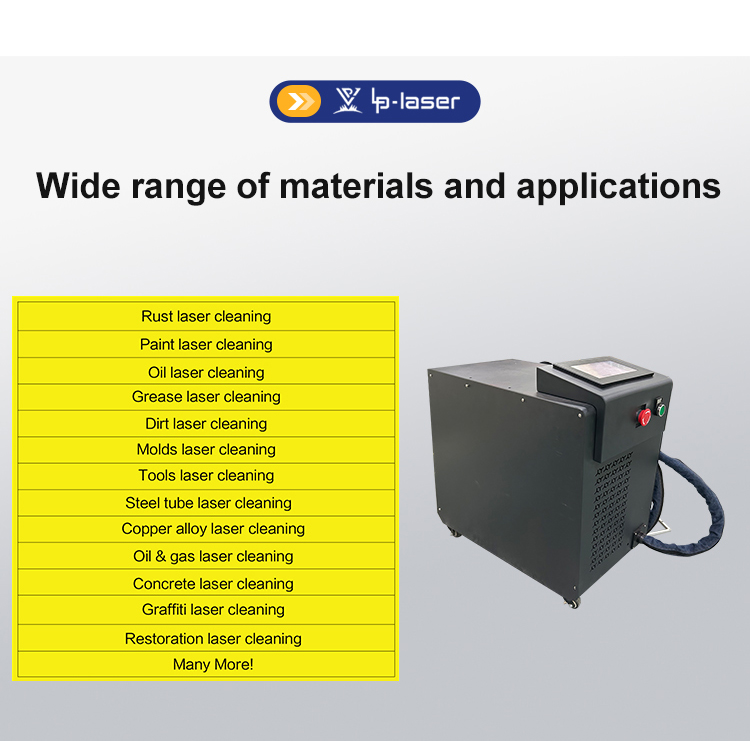

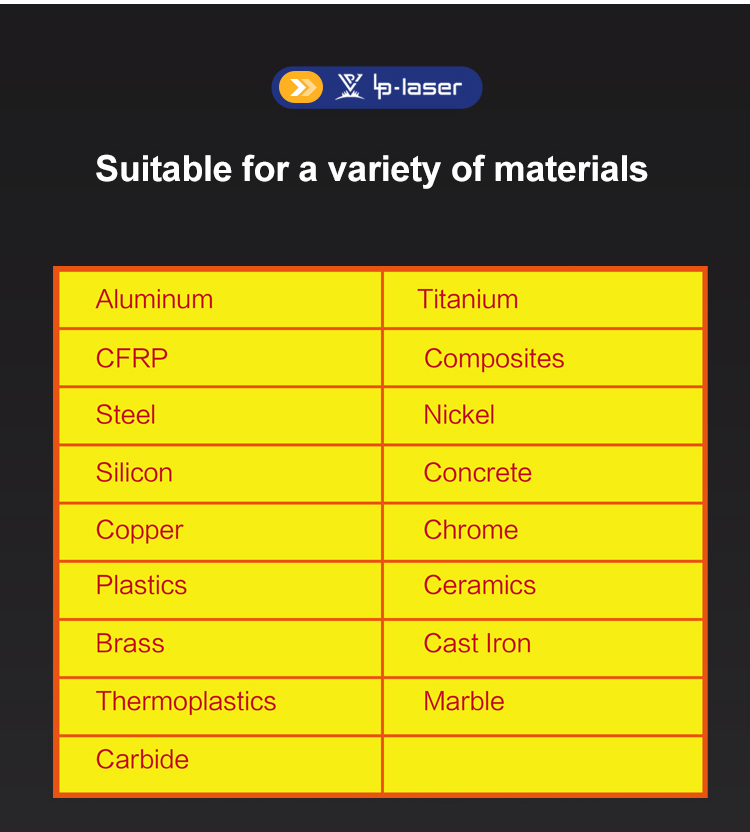

6.Versatile

7.Minimal Thermal Impact

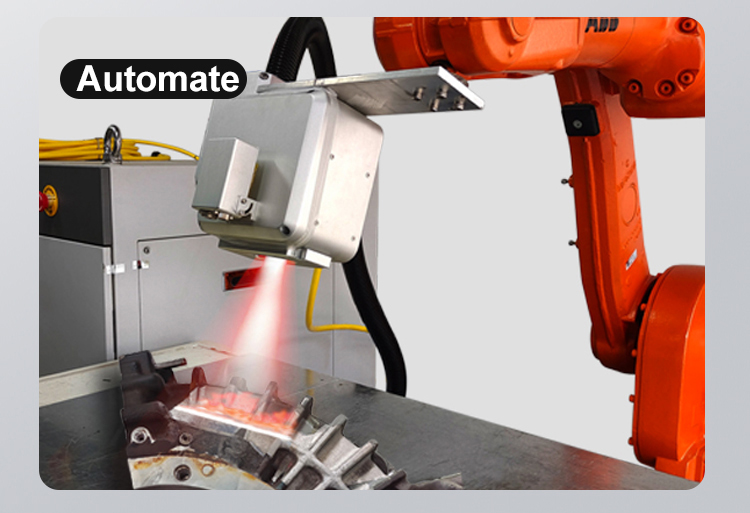

8.Easy to Integrate and Automate

Product introduction

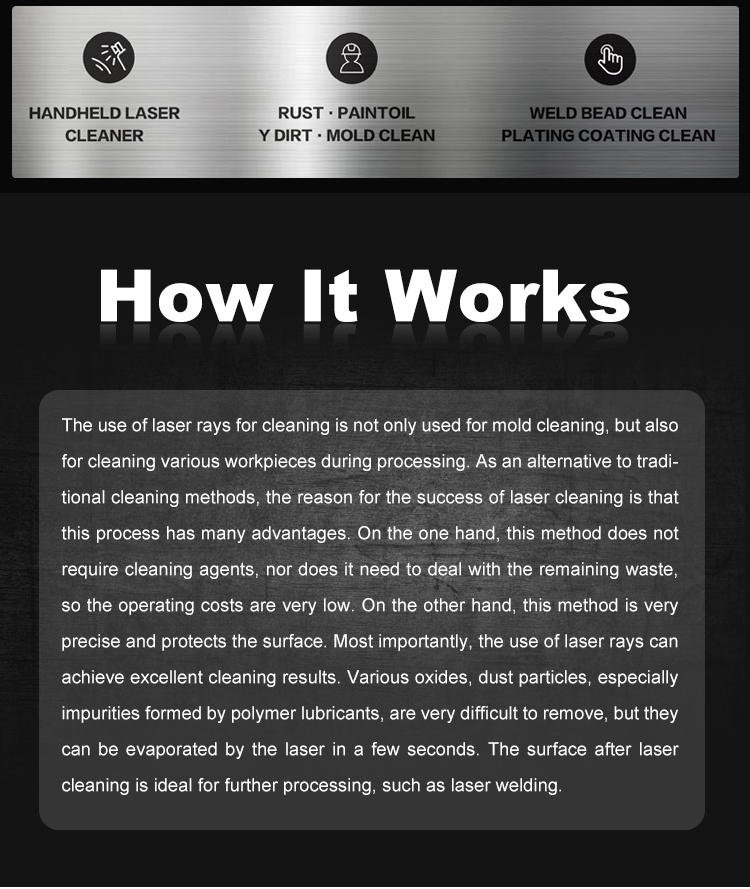

Laser ray cleaning technology is not only widely used in the cleaning of molds, but also become a method of cleaning various workpieces in the processing process. As an innovator of traditional cleaning technology, the reason for its success lies in its unique and significant advantages.

First of all, laser cleaning completely gets rid of the need for chemical cleaning agents, but also eliminates the trouble of dealing with the waste after cleaning. This not only greatly reduces operating costs, but also greatly simplifies the cleaning process, making the whole process more environmentally friendly and efficient.

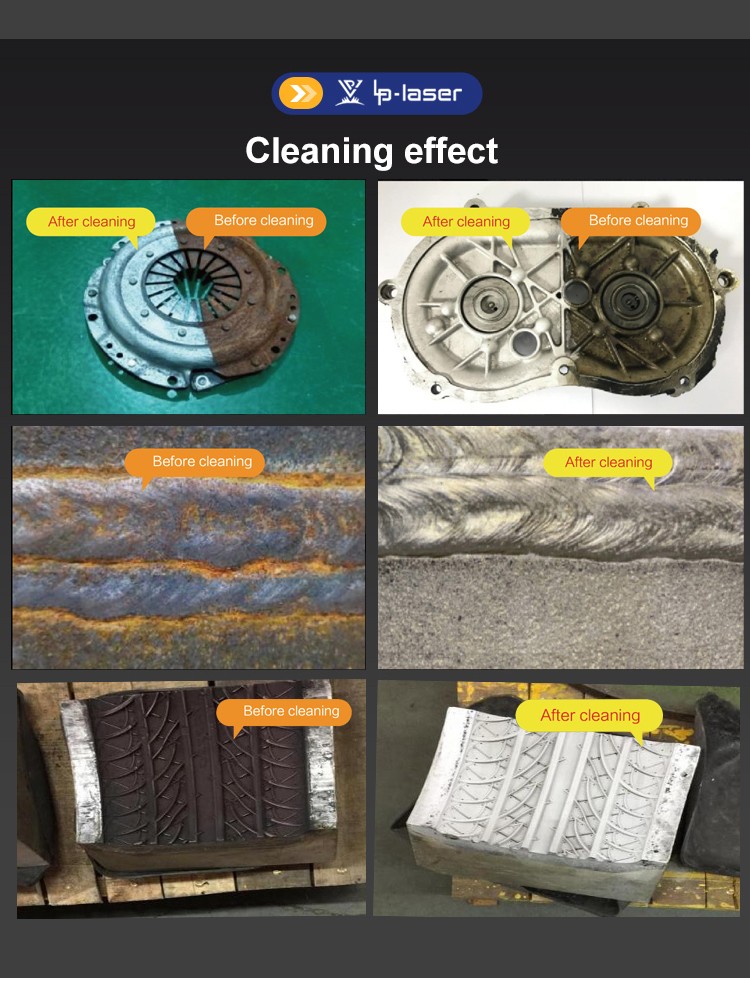

Second, the accuracy of laser cleaning technology is impressive. By precisely controlling the focus and energy distribution of the laser beam, the target area can be cleaned efficiently and precisely, while avoiding any damage to the surrounding area. This non-contact cleaning method effectively protects the integrity of the workpiece surface and ensures its processing quality.

Most importantly, the laser cleaning technology has shown excellent cleaning results. Even those hard-to-remove oxides, dust particles, and stubborn impurities formed by polymer lubricants can quickly evaporate under laser light, leaving no trace. This efficient cleaning capability makes laser cleaning technology ideal for handling complex, fine workpiece cleaning tasks.

In addition, the surface quality of the workpiece after laser cleaning is good, smooth and no residue, which provides ideal conditions for subsequent processing operations. For example, the surface of the workpiece after laser cleaning can be directly processed with high precision, such as laser welding, without additional processing or preparation steps, which greatly improves the processing efficiency and quality.

| Model: | HLC-P100W | HLC-P200W |

| Operational Voltage: | 220V±10%、50/60Hz Customizable: 110V, 50Hz AC | |

| Temperature: | 5℃~40℃ | |

| Humidity: | 30-85% Non-Condensing | |

| Power dissipation: | ≤1000W | ≤1500W |

| Power Output: | 100W | 200W |

| Laser Type: | Optical fiber | |

| Maximum Pulse Energy: | 1.5mJ | 1.5mJ |

| Pulse Frequency Range: | 1-3000kHz(Gradient adjustable) | 1-3000kHz(Gradient adjustable) |

| Pulse Width: | 13-500ns tunable | 13-500ns tunable |

| Output Power Instability: | <5% | |

| Wavelength: | 1064 nm | |

| Head Cable Length: | 3 m | 3 m |

| Cooling: | Air cooling | |

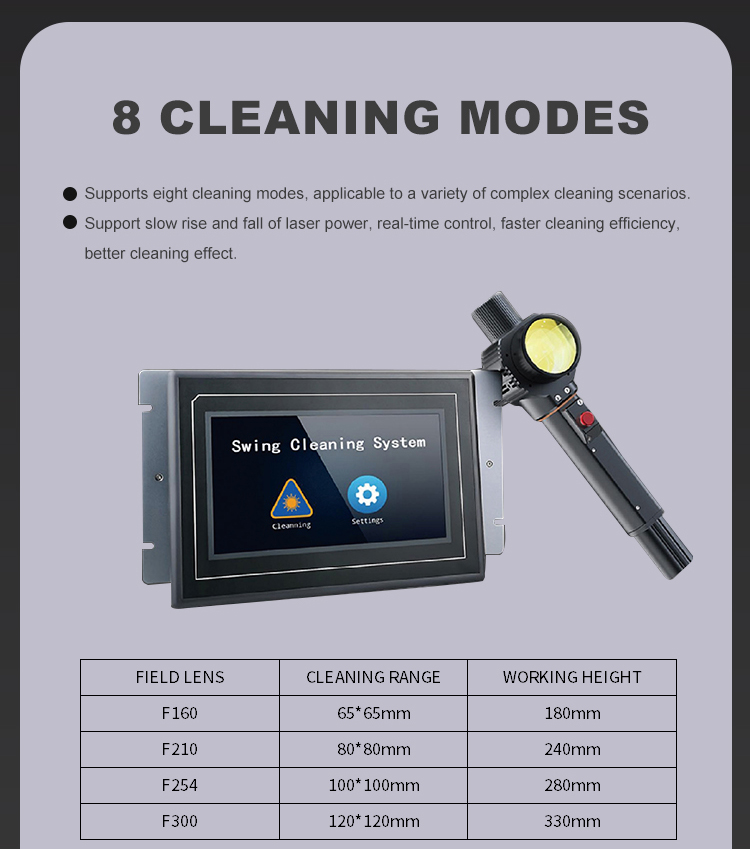

| Focus Distance: | 160mm | 254mm |

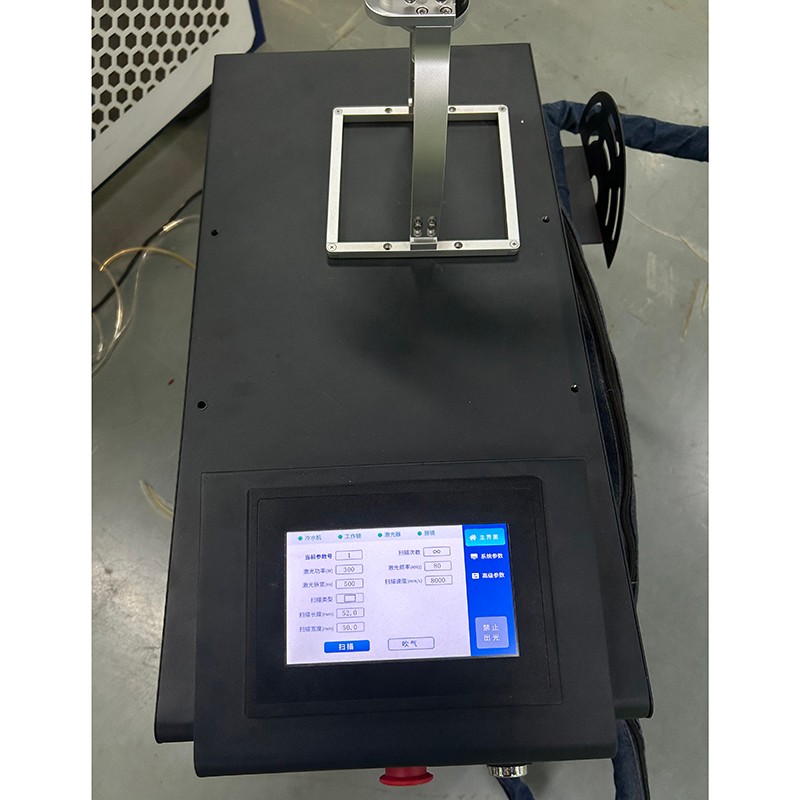

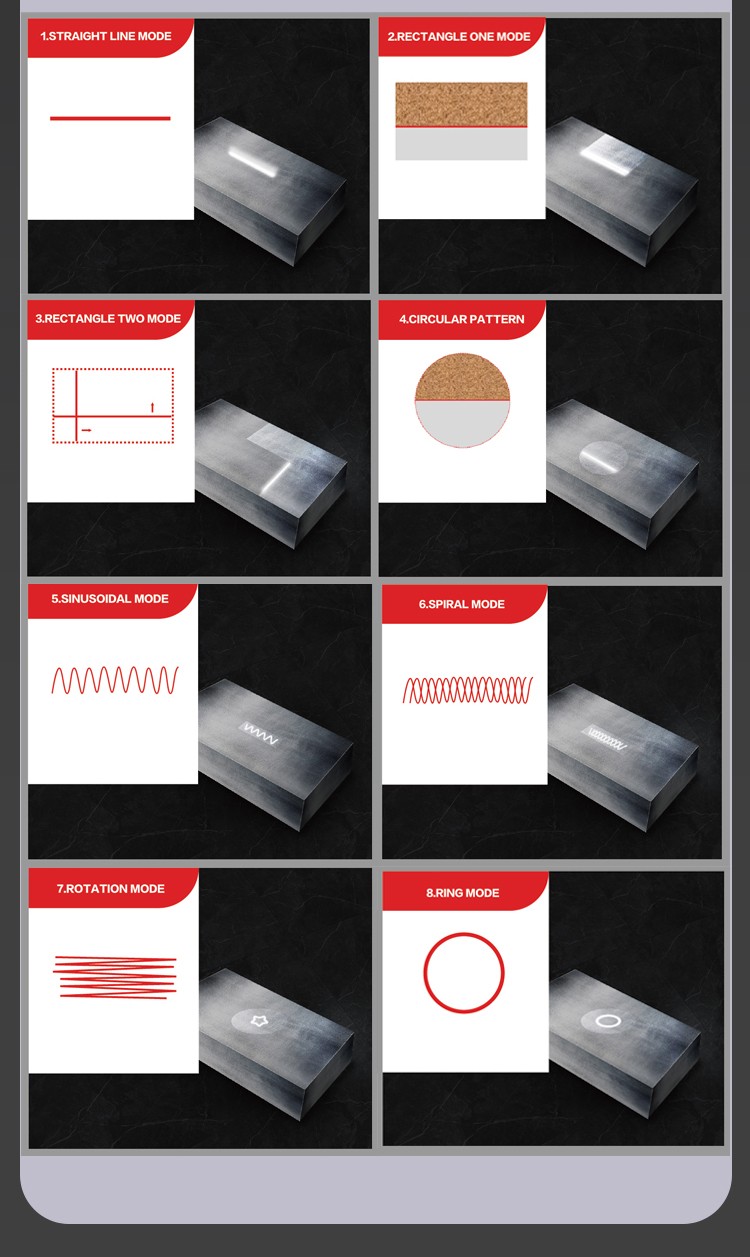

| Scanning mode: | Dual axis; Nine scanning modes are supported | |

| Head Weight: | ≤0.9Kg | ≤0.9Kg |

| Size W x H x D: | About350mm*152mm*250mm | |

| Box Dimensions | ||

| Entire Unit Weight: | About 12Kg | About 18Kg |

| Packed weight: | About 20Kg | About 26Kg |

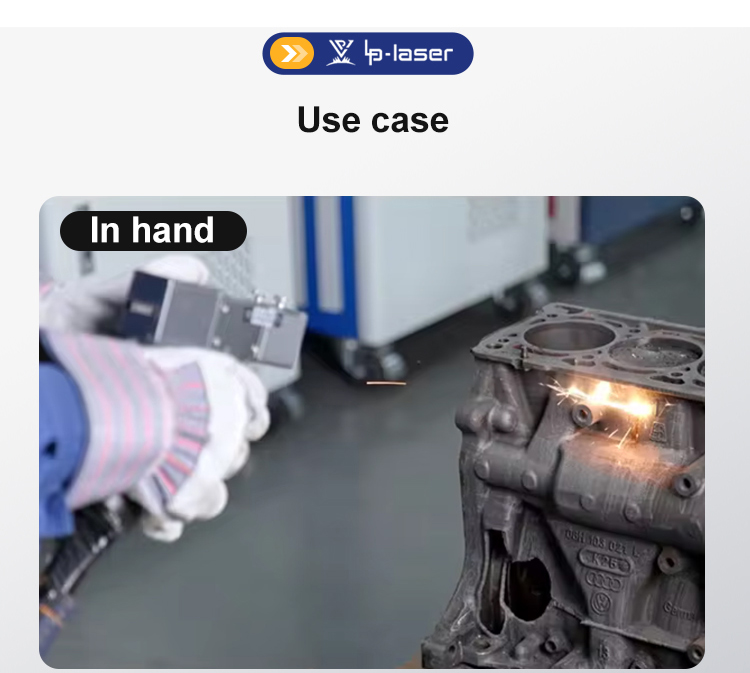

| Operation Mode: | Handheld/Automation | Handheld/Automation |

| Safety Class: | Level IV | Level IV |

Q1: What's next in laser cleaning?

A: Blue lasers (450nm) for better copper cleaning; ultrafast (ps/fs) for nanometer precision.

Q2: How is automation evolving?

A: AI-powered parameter optimization and robotic path planning becoming standard.

Q3: Are portable systems improving?

A: Yes - battery-powered handhelds now available (1-2 hour runtime).

Q4: What about green lasers?

A: 515nm systems show promise but currently have higher costs.

Q5: Safety advancements?

A: Smart sensors detecting reflections with auto-power adjustment/shutdown.