Laser Marking Machine

High Precision:

Laser marking machines can produce detailed marks with high accuracy, even on small and intricate parts. This is crucial in industries such as electronics and aerospace, where small parts require detailed marking.

Wide Material Compatibility:

They can mark a wide range of materials, including metals, plastics, ceramics, glass, rubber, and more. This adaptability eliminates the need for multiple specialized marking machines for different materials.

Fast Marking Speed:

They can create marks quickly and efficiently, making them ideal for high - volume production environments. This helps to reduce production costs by allowing for faster processing times.

Permanent Markings:

The marks created by laser marking machines are permanent and resistant to wear and tear, fading, and corrosion. This is important for product identification, traceability, and brand protection.

Non - contact Marking:

The non - contact marking method eliminates the risk of mechanical wear and tear on the marking head and the materials being marked. It also reduces the likelihood of damage and material waste, especially when working with delicate or fragile materials.

High Quality:

The quality of markings is easily readable by both humans and machines, which simplifies component identification and assembly on the production floor and is also helpful for end - consumers when they use the products.

Versatile:

Laser markings and engraving can be done on many surfaces that are otherwise tough to work with, enabling a wide range of applications in different industries.

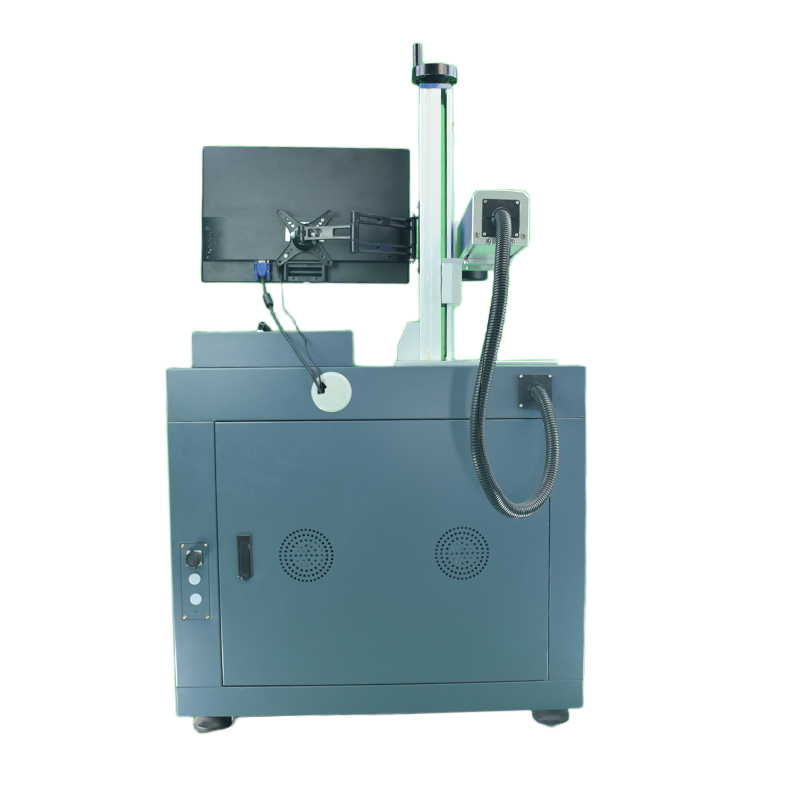

What is a Laser Marking Machine

A laser marking machine is a device that uses a laser beam to create permanent marks on a variety of materials. It works by directing a high - powered laser beam onto the surface of the material, causing the material to fuse, vaporize, or discolor, thereby creating a mark that is resistant to wear and tear.

Types of Laser Marking Machines

Fiber Laser Marking Machine: It is mainly suitable for marking metal materials and is also known as a metal laser marking machine. It has the characteristics of good beam quality, small size, fast speed, long working life, flexible and convenient installation, and being maintenance - free. It can also process plastics, electronics, ceramics, tobacco, and other materials.

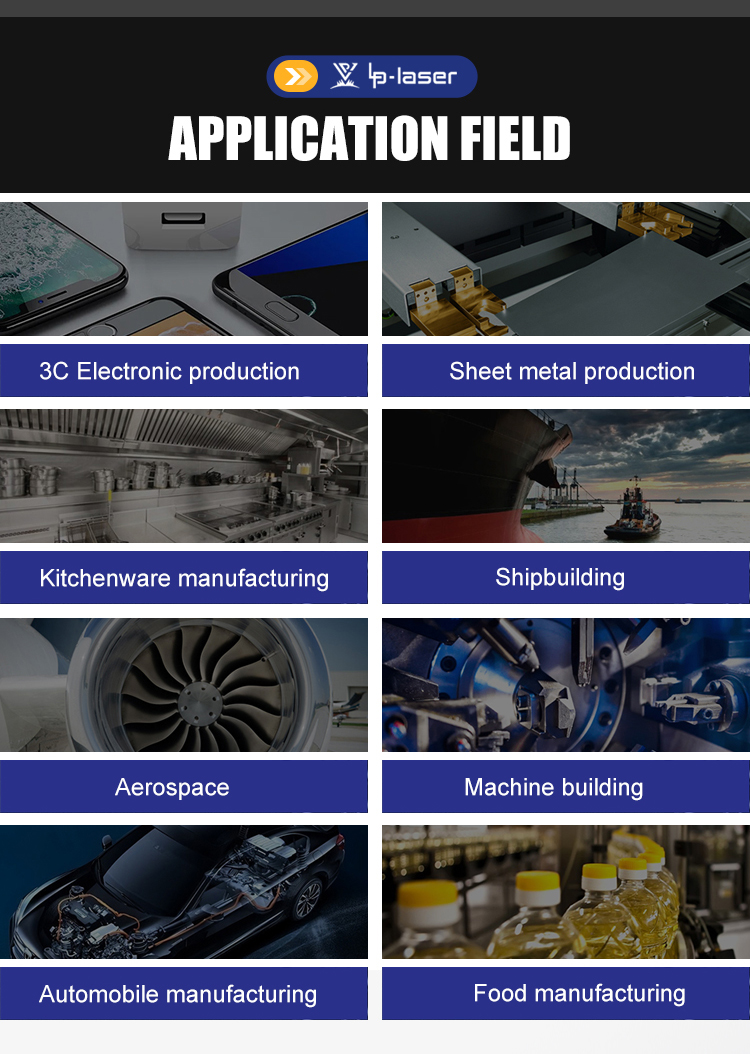

Applications of Laser Marking Machines

The application of laser marking machines is very extensive, mainly including electronic components, integrated circuits, electrical appliances, mobile communications, hardware products, tool accessories, precision equipment, glasses, watches, jewelry, auto parts, food, medicine, wine, building materials, PVC pipes, and other fields.

| Laser Type | Fiber Laser |

| Power | 20w/30w/50w |

| Laser Source Brand | MAX /RAYCUS/ JPT MOPA Optional |

| Compatible with Lightburn | Yes |

| Language | Chinese,Korean,Japanese, German, FrenchArabic,Spanish, Portuguese, Vietnamese, FarsiRussian, Thai,etc. |

| Cooling Mode | Air Cooling |

| Net Weight | 75kg |

1.Q: How does the wide material adaptability of fiber marking machines affect their cost - effectiveness?

A: The ability to mark various materials means that one fiber marking machine can replace multiple specialized marking machines for different materials. This reduces the initial investment and long - term maintenance costs.

2.Q: Are there additional costs when marking different materials with a fiber marking machine?

A: Generally, there are no significant additional costs. The machine can adjust its parameters for different materials without the need for major hardware changes. However, in some cases, special marking fluids or fixtures might be required, but these are usually minimal expenses.

3.Q: Can fiber marking machines mark delicate materials without increasing costs due to potential damage?

A: Since fiber marking machines use non - contact marking, the risk of damaging delicate materials is low. This eliminates the cost of material waste due to damage, making them a cost - effective option for marking sensitive products.

4.Q: For rare metal marking, is the cost - performance of fiber marking machines still high?

A: Yes. Fiber marking machines can mark rare metals precisely, which is crucial for maintaining the value of these expensive materials. Their high - precision reduces the risk of material loss during the marking process, making them cost - effective for rare metal applications.

5.Q: Do fiber marking machines require additional setup costs for different materials?

A: The marking software of fiber marking machines is highly flexible. It can be easily configured for different materials with minimal setup time and cost. In most cases, users only need to adjust some parameters in the software, without the need for additional hardware installations.