High Quality Laser Marking Machine

High Precision:

Laser marking machines can produce detailed marks with high accuracy, even on small and intricate parts. This is crucial in industries such as electronics and aerospace, where small parts require detailed marking.

Wide Material Compatibility:

They can mark a wide range of materials, including metals, plastics, ceramics, glass, rubber, and more. This adaptability eliminates the need for multiple specialized marking machines for different materials.

Fast Marking Speed:

They can create marks quickly and efficiently, making them ideal for high - volume production environments. This helps to reduce production costs by allowing for faster processing times.

Permanent Markings:

The marks created by laser marking machines are permanent and resistant to wear and tear, fading, and corrosion. This is important for product identification, traceability, and brand protection.

Non - contact Marking:

The non - contact marking method eliminates the risk of mechanical wear and tear on the marking head and the materials being marked. It also reduces the likelihood of damage and material waste, especially when working with delicate or fragile materials.

High Quality:

The quality of markings is easily readable by both humans and machines, which simplifies component identification and assembly on the production floor and is also helpful for end - consumers when they use the products.

Versatile:

Laser markings and engraving can be done on many surfaces that are otherwise tough to work with, enabling a wide range of applications in different industries.

What is a Laser Marking Machine

A laser marking machine is a device that uses a laser beam to create permanent marks on a variety of materials. It works by directing a high - powered laser beam onto the surface of the material, causing the material to fuse, vaporize, or discolor, thereby creating a mark that is resistant to wear and tear.

Types of Laser Marking Machines

Fiber Laser Marking Machine: It is mainly suitable for marking metal materials and is also known as a metal laser marking machine. It has the characteristics of good beam quality, small size, fast speed, long working life, flexible and convenient installation, and being maintenance - free. It can also process plastics, electronics, ceramics, tobacco, and other materials.

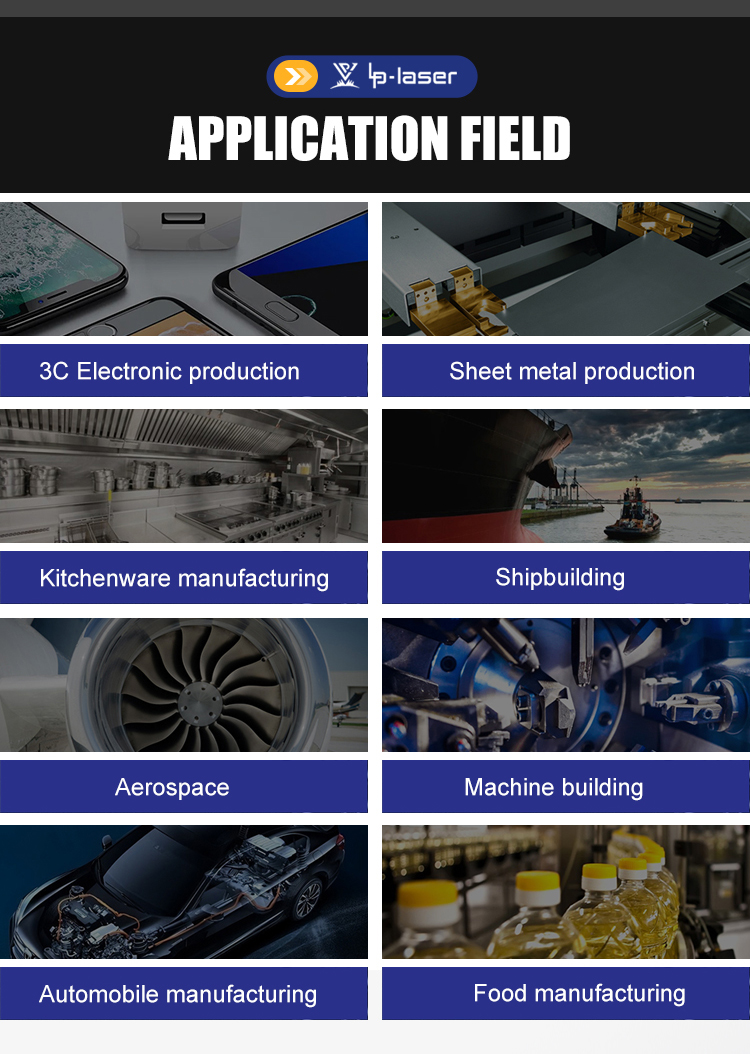

Applications of Laser Marking Machines

The application of laser marking machines is very extensive, mainly including electronic components, integrated circuits, electrical appliances, mobile communications, hardware products, tool accessories, precision equipment, glasses, watches, jewelry, auto parts, food, medicine, wine, building materials, PVC pipes, and other fields.

Why Choose Our Laser Marking Machine?

✅ Industrial-Grade Durability – Built for 24/7 operation.

✅ High Precision (Up to 0.01mm Accuracy) – Perfect for micro-markings.

✅ Energy Efficient – Lower operational costs than traditional methods.

✅ Customizable Solutions – Tailored to your production needs.

| Laser Type | Fiber Laser |

| Power | 20w/30w/50w |

| Laser Source Brand | MAX /RAYCUS/ JPT MOPA Optional |

| Compatible with Lightburn | Yes |

| Language | Chinese,Korean,Japanese, German, FrenchArabic,Spanish, Portuguese, Vietnamese, FarsiRussian, Thai,etc. |

| Cooling Mode | Air Cooling |

| Net Weight | 75kg |

1.Q: How does the fast marking speed of fiber marking machines improve cost - effectiveness in production?

A: Faster marking speeds mean higher production volumes in the same time period. This increases the throughput of the production line, reducing the unit cost of each marked product and improving overall profitability.

2.Q: Does the high - speed marking of fiber marking machines affect the quality of the marks, and will it lead to rework costs?

A: No, fiber marking machines maintain high - quality marking even at high speeds. Their advanced control systems ensure that the marks are clear and consistent, minimizing the risk of rework and associated costs.

3.Q: Can the fast marking speed of fiber marking machines adapt to different production schedules?

A: Yes, the adjustable marking speed allows the machine to be tailored to different production requirements. Whether it's a tight deadline for a large order or a slower pace for a small, customized batch, the fiber marking machine can adjust accordingly.

4.Q: Do I need to invest in additional training for my staff to operate the fiber marking machine at high speeds?

A: Our fiber marking machines are designed with user - friendly interfaces. While some basic training is recommended, the intuitive operation makes it easy for staff to learn how to operate the machine at high speeds without excessive training costs.

5.Q: How does the fast marking speed of fiber marking machines compare to traditional marking methods in terms of cost - savings?

A: Compared to traditional methods, fiber marking machines can complete marking tasks much faster. This reduces labor costs associated with manual or slower - paced marking processes, and also enables quicker turnover of products, resulting in significant cost savings.