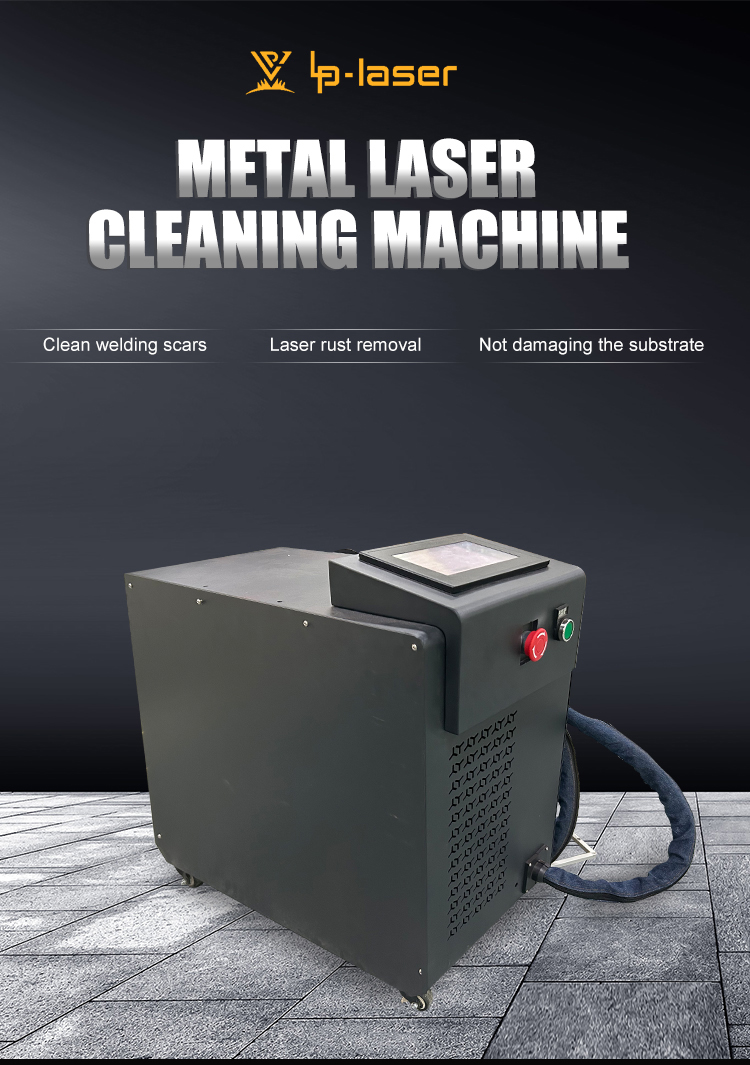

Factory Direct Supply Metal Laser Cleaning Machine

1. High Precision and Selectivity

Metal laser cleaning machines offer unrivaled precision. The laser beam can be accurately focused on specific areas of the metal surface.

2.Non - Abrasive and Non - Contact

3.Environmentally Friendly

4.High Efficiency

5.Cost - Effective Long - Term

6.Versatile

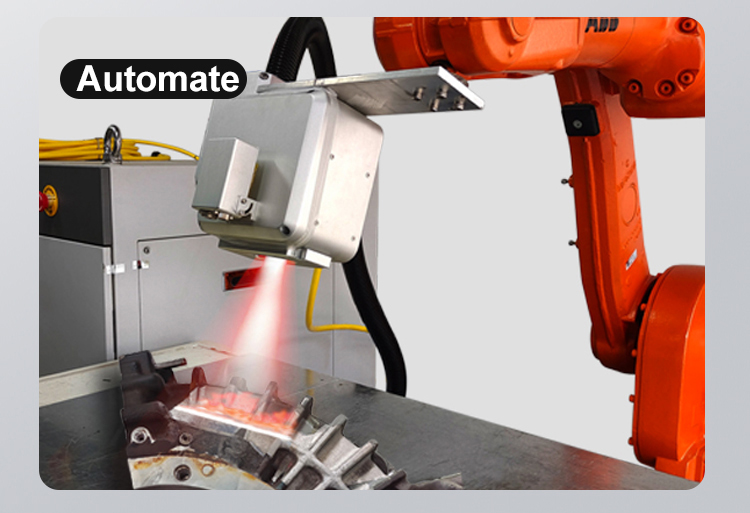

7.Minimal Thermal Impact

8.Easy to Integrate and Automate

Product introduction

Laser cleaning technology has evolved from a niche mold-cleaning solution to a comprehensive surface treatment method for diverse industrial workpieces. This innovative approach has successfully disrupted traditional cleaning methodologies through its unparalleled advantages:

1. Eco-Conscious Operation

Unlike conventional methods, laser cleaning eliminates the need for chemical solvents entirely, thereby:

Removing hazardous waste disposal requirements

Reducing operational costs by up to 60%

Simplifying workflow processes

Achieving zero liquid effluent discharge

2. Unmatched Precision

The technology's precision stems from its advanced beam control capabilities:

Micron-level focal spot adjustment (50μm-5mm)

Real-time energy density modulation (5-20J/cm²)

Non-contact processing preserves substrate integrity

Selective removal of contaminants without affecting base materials

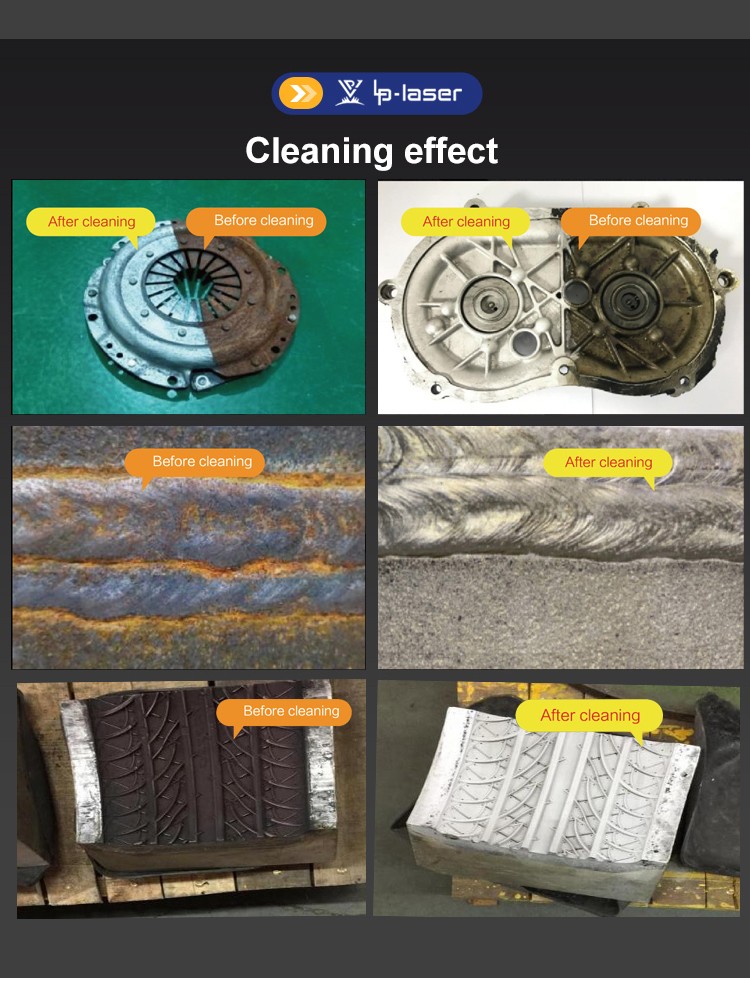

3. Superior Cleaning Performance

Laser cleaning demonstrates exceptional efficacy on:

Tenacious oxides (including Cr2O3 and Al2O3)

Submicron particulate contamination

Polymerized lubricant residues

Surface coatings up to 500μm thickness

4. Enhanced Surface Preparation

Post-cleaning surfaces exhibit:

Optimal Sa surface roughness (0.1-1.6μm)

100% residue-free conditions

Activated surface energy (72+ mN/m)

Ideal metallurgical properties for subsequent processes

The technology's compatibility with follow-up precision operations like laser welding eliminates preparatory steps, reducing processing time by 30-50% while improving joint quality. This makes laser cleaning particularly valuable for applications demanding high-precision surface conditions, such as aerospace component manufacturing and medical device production.

| Model: | HLC-P100W | HLC-P200W |

| Operational Voltage: | 220V±10%、50/60Hz Customizable: 110V, 50Hz AC | |

| Temperature: | 5℃~40℃ | |

| Humidity: | 30-85% Non-Condensing | |

| Power dissipation: | ≤1000W | ≤1500W |

| Power Output: | 100W | 200W |

| Laser Type: | Optical fiber | |

| Maximum Pulse Energy: | 1.5mJ | 1.5mJ |

| Pulse Frequency Range: | 1-3000kHz(Gradient adjustable) | 1-3000kHz(Gradient adjustable) |

| Pulse Width: | 13-500ns tunable | 13-500ns tunable |

| Output Power Instability: | <5% | |

| Wavelength: | 1064 nm | |

| Head Cable Length: | 3 m | 3 m |

| Cooling: | Air cooling | |

| Focus Distance: | 160mm | 254mm |

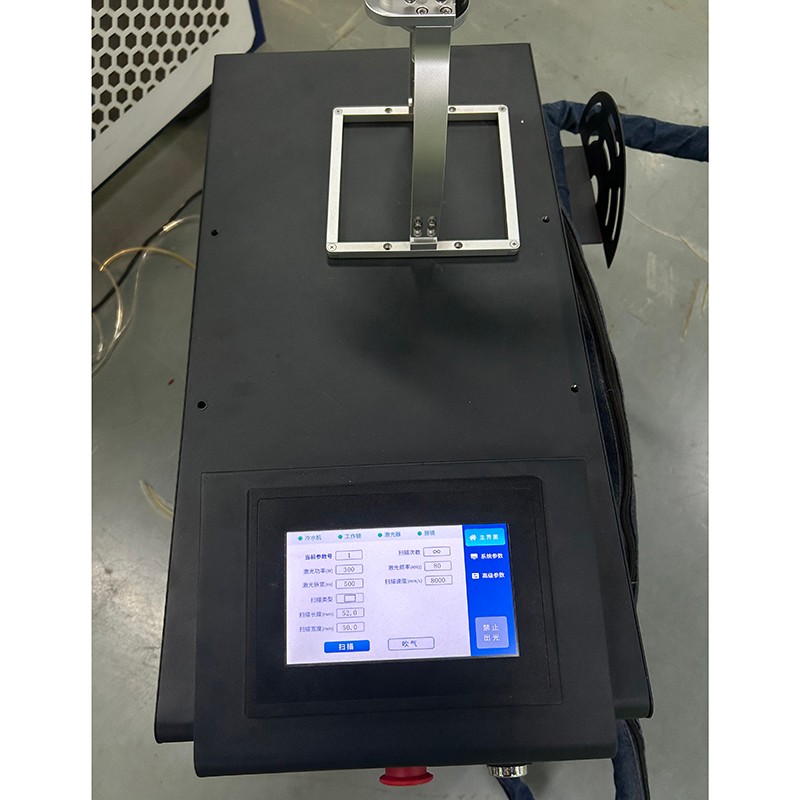

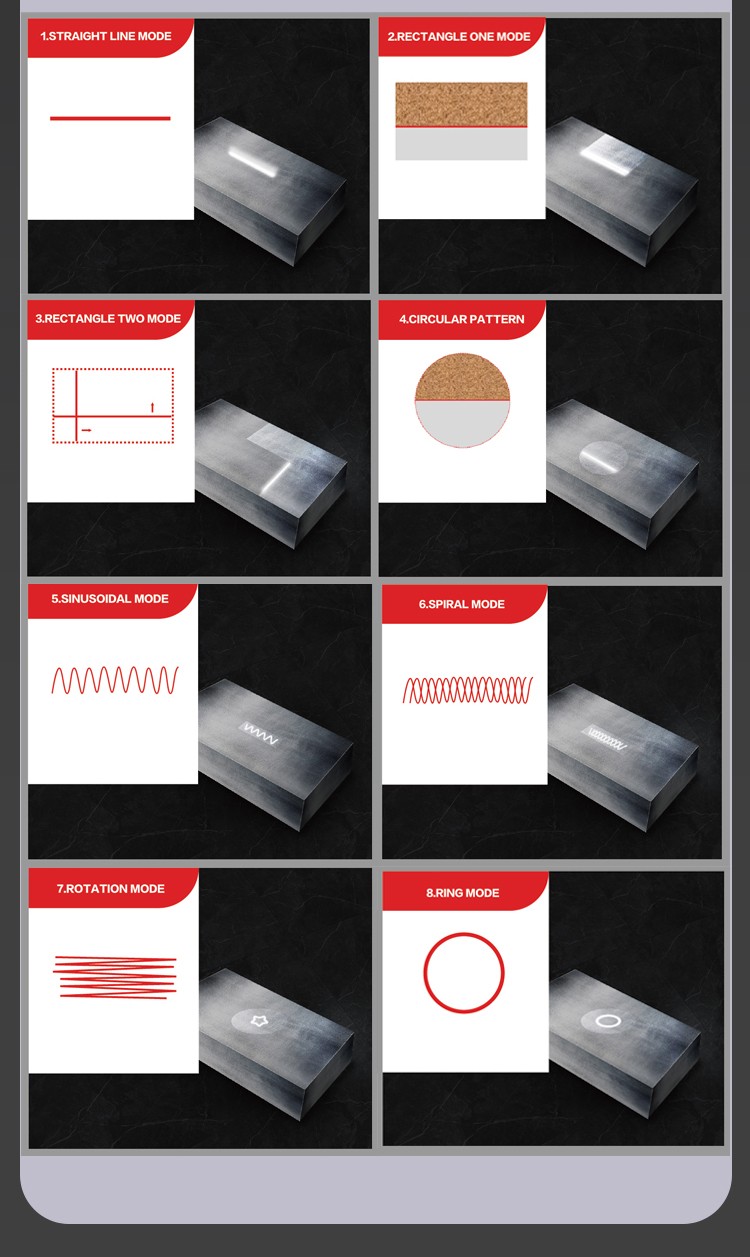

| Scanning mode: | Dual axis; Nine scanning modes are supported | |

| Head Weight: | ≤0.9Kg | ≤0.9Kg |

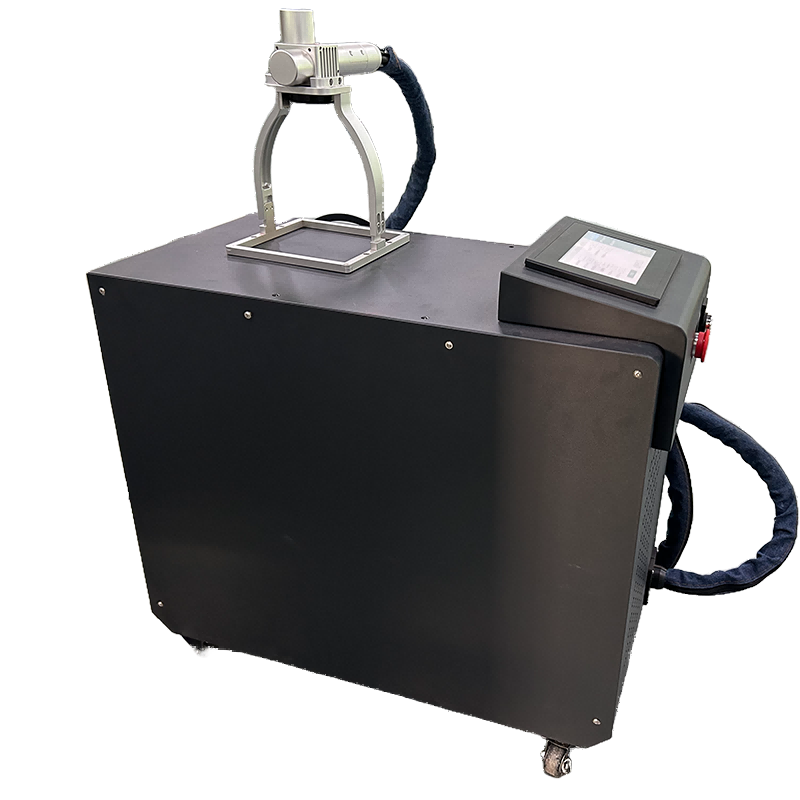

| Size W x H x D: | About350mm*152mm*250mm | |

| Box Dimensions | ||

| Entire Unit Weight: | About 12Kg | About 18Kg |

| Packed weight: | About 20Kg | About 26Kg |

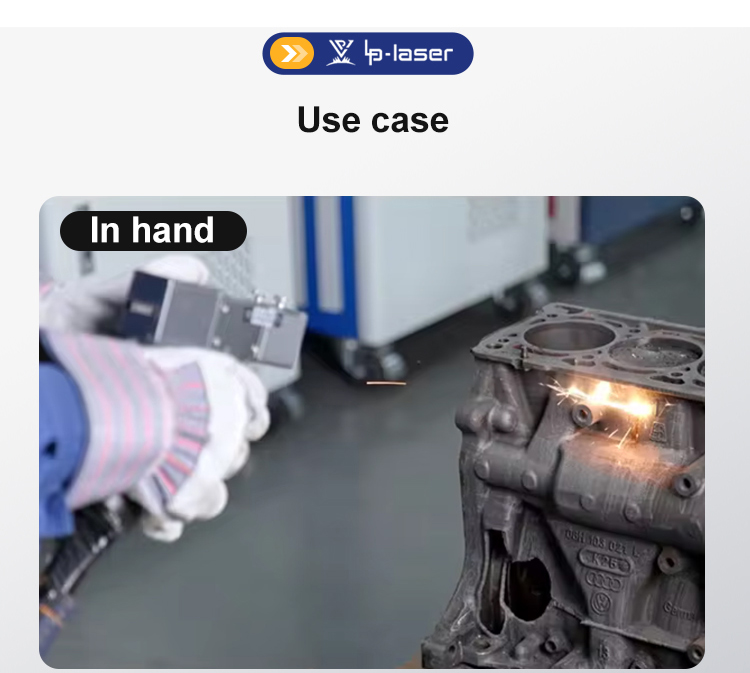

| Operation Mode: | Handheld/Automation | Handheld/Automation |

| Safety Class: | Level IV | Level IV |

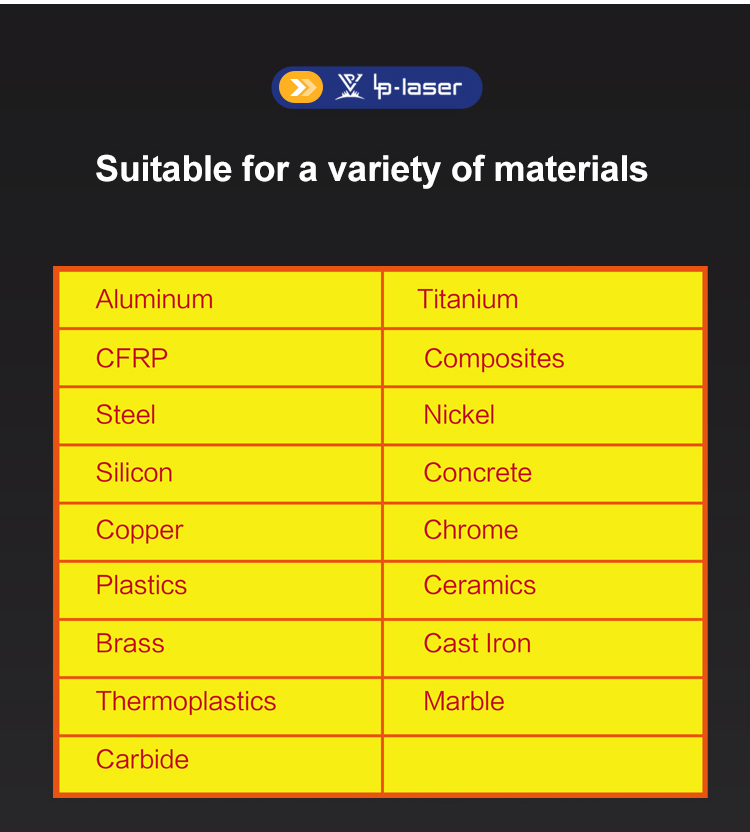

1. What materials can be cleaned with a laser cleaner?

Aluminium - Carbon fibre reinforced plastics - Steel - Silicon - Copper - Plastic - Copper - Thermoplastics -Titanium - composite materials - nickel - chromium - ceramics - cast iron - marble - carbide, etc.

2. Is there any damage to the cleaning material?

Pulse type has finer cleaning effect while continuous type has faster cleaning speed, relative to material damage, pulse type is less than continuous type. By optimising the algorithm and increasing the speed, we can achieve basically no damage to the substrate.

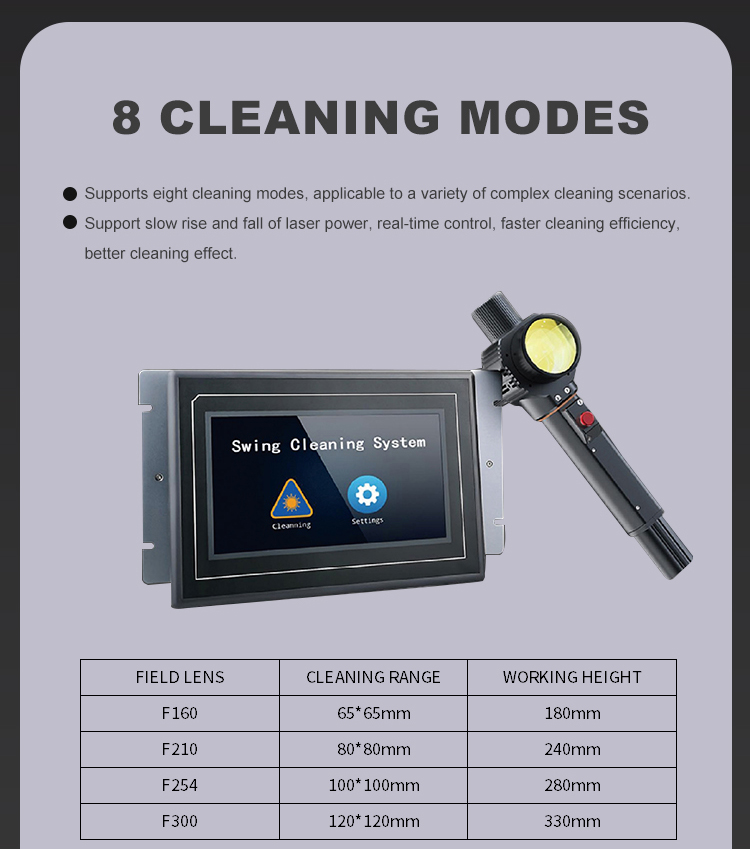

3. How many cleaning modes are currently supported?

Currently, we support 9 modes: Linear, Rectangle I, Rectangle II, Circle, Sine, Spiral, Free, Circle and Rotary.

3. Language interface

Currently support Chinese, Chinese traditional, English, Russian, Japanese, Spanish, German, Korean, French and other 16 languages

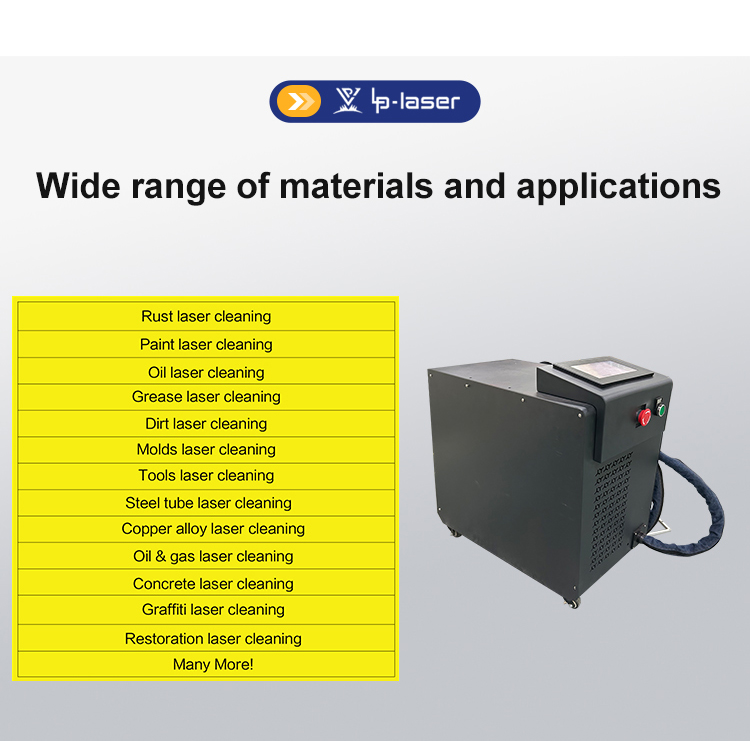

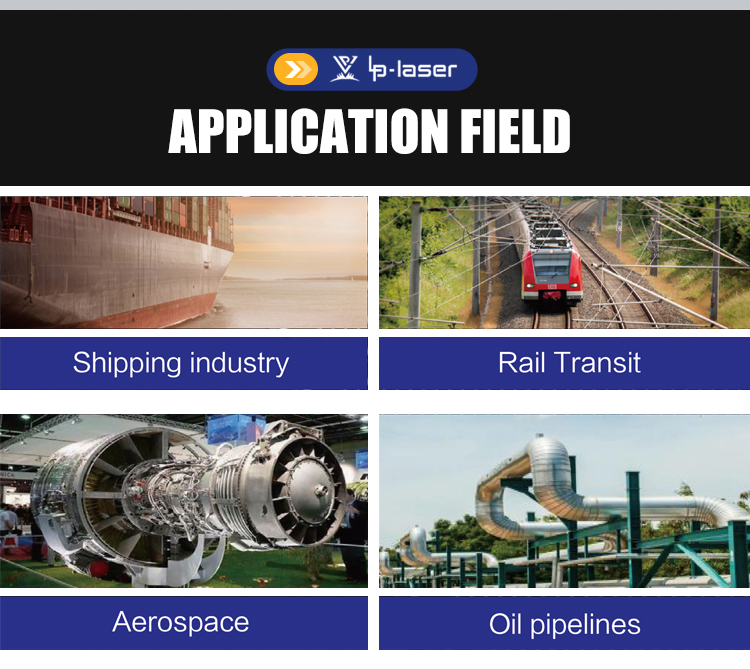

4.Product Application

This machine is suitable for removing all kinds of stains, including rust layer, paint, oil, coating, oxidation layer, adherence on stone statues (detailed to dust level), and rubber moulding residue. In addition, it is also suitable for pre-treatment of welded/painted surfaces.