Multifunctional Fiber Laser Welding Machine

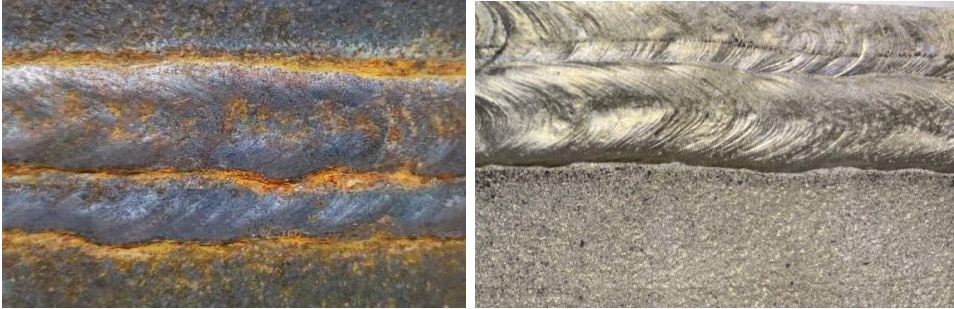

1.High Precision: Fiber lasers provide a highly focused beam with excellent beam quality, allowing for precise and intricate welding with minimal heat-affected zones.

2.High Efficiency: Fiber lasers are known for their high electrical-to-optical conversion efficiency, which means they consume less power compared to other types of lasers.

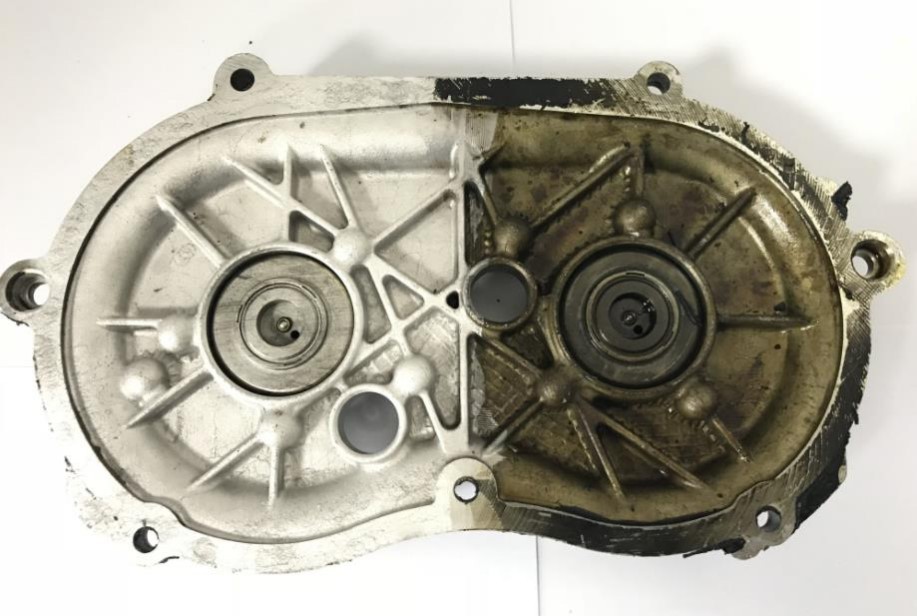

3.Versatility: Fiber laser welding machines can be used to weld a wide range of materials, including stainless steel, aluminum, copper, and other alloys, with varying thicknesses.

4.Adjustable Parameters: The machine allows for the adjustment of key parameters such as laser power, pulse frequency, pulse width, and spot size to optimize the welding process for different materials and applications.

How Fiber Laser Welding Machine Works?

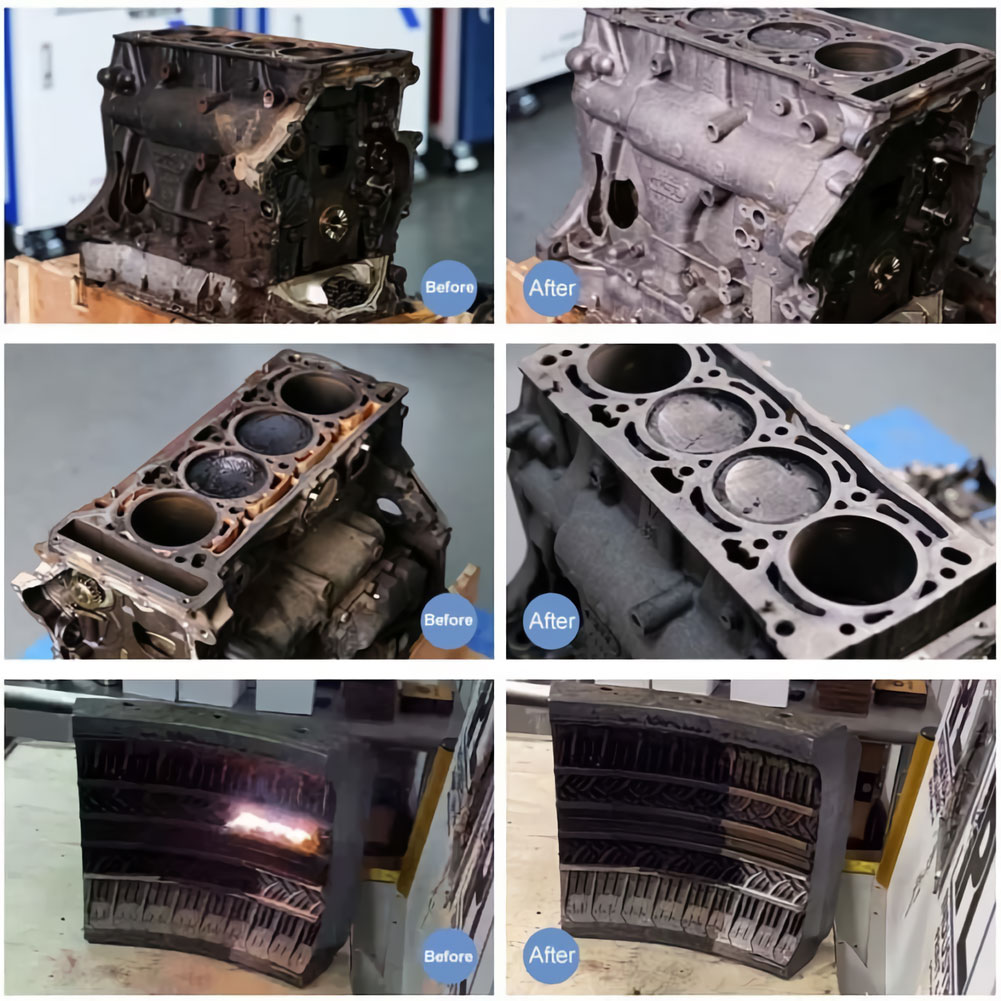

The fiber laser welding machine uses laser rays for cleaning, not only for mould cleaning, but also for the cleaning of various workpieces in the process. The success of laser cleaning as an alternative to conventional cleaning methods is due to the many advantages of this process. On the one hand, it does not require cleaning agents or the disposal of residual waste, and therefore has very low operating costs. On the other hand, it is very precise and protects the surface. Above all, the use of laser rays achieves excellent cleaning results. All kinds of oxides, dust particles and especially impurities formed by polymer lubricants, which are very difficult to remove, can be evaporated by the laser in a matter of seconds. The laser-cleaned surfaces are ideally suited for further processing, such as laser welding.

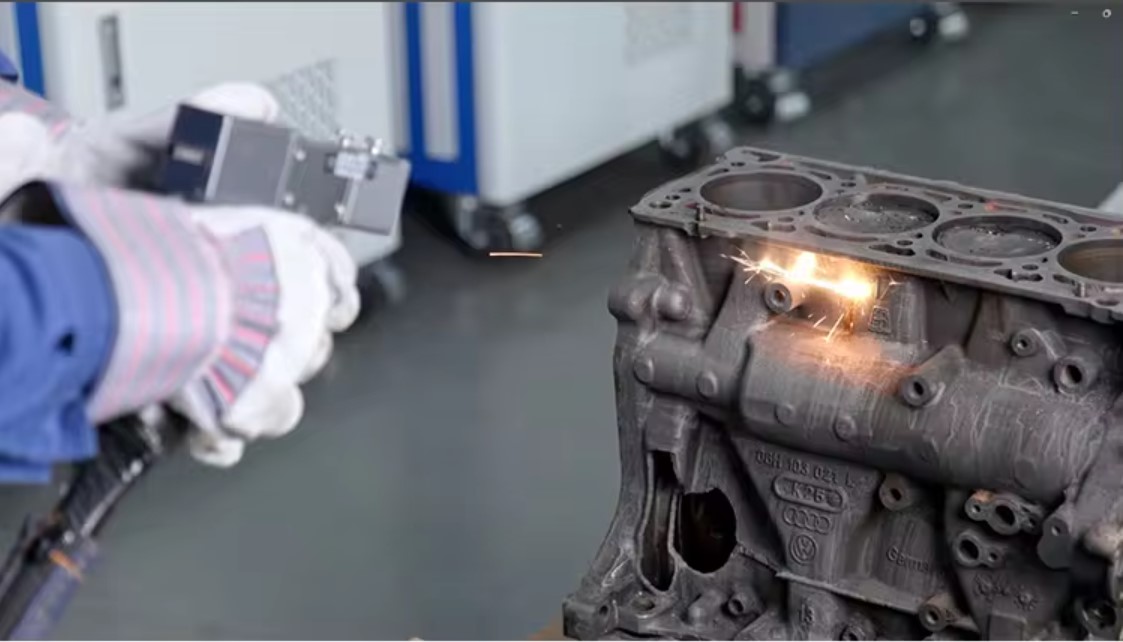

Sample Photos:

Product Parameter:

Model: | HLC-P200W | HLC-P300W | HLC-P300W |

Operational Voltage: | 220V±10%、50/60Hz customisable:110V、50H zalternating current | ||

Temperature: | 5℃ ~40℃ | ||

Humidity: | 30-85% Non-Condensing | ||

Power dissipation: | ≤1500W | ≤2000W | ≤4000W |

Power Output: | 200W | 300W | 300W |

Laser Type: | Fibre | ||

Maximum Pulse Energy: | 1.5mJ/2mJ/5mJ | 1.5mJ/5mJ | 12.5mJ |

Pulse Frequency Range: | 1-4000kHz(Gradient adjustable) | 1-4000kHz(Gradient adjustable) | 1-4000kHz(Gradient adjustable) |

Pulse Width: | 2-500ns tunable | 2-500ns tunable | 2-500ns tunable |

Output Power Instability: | <5% | ||

Wavelength: | 1064 nm | ||

Head Cable Length: | 5 m | 5 m | 5 m |

Cooling: | air cooling | water cooling | |

Focus Distance: | 210mm | 210mm | 210mm |

Scanning mode: | Dual-axis; supports 9 scanning modes | ||

Head Weight: | ≤0.9Kg | ≤1.25Kg | |

Size W x H x D: | About 629mm*341mm*734mm | About 982mm*458mm*791mm | |

Box Dimensions | About 800mm*470mm*880mm | About 1130mm*580mm*1050mm | |

Entire Unit Weight: | About 52Kg | About 52Kg | About 135Kg |

Packed weight: | About 67Kg | About 67Kg | About 165Kg |

Operation Mode: | Handheld/Automation | ||

Safety Class: | Level IV | ||

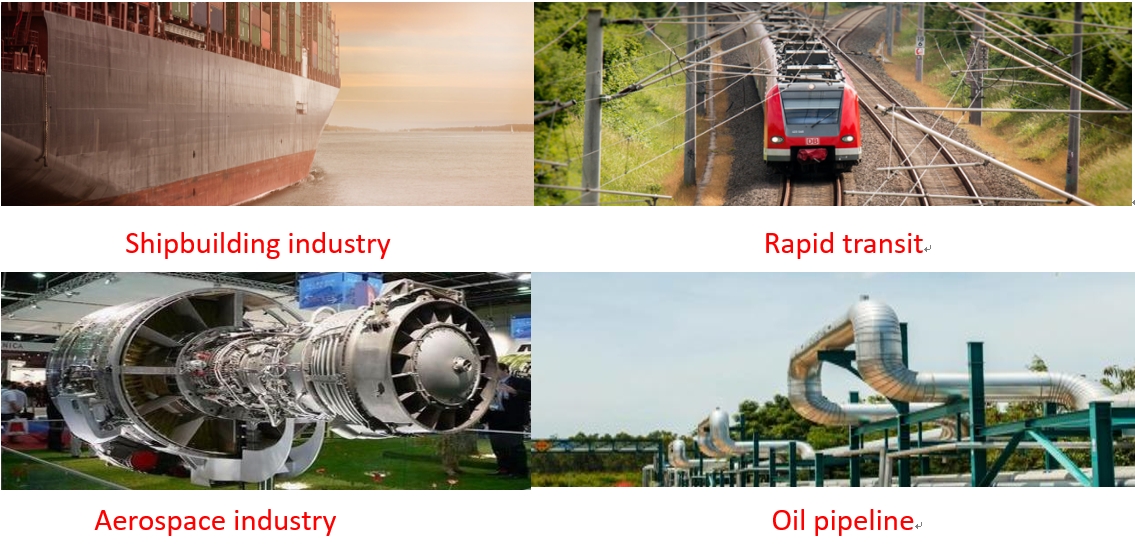

Application:

Use Cases:

FAQ:

Q1: How do you ensure quality control?

A: 100% burn-in testing + ISO 9001 audits—our defect rate is <0.3%, matching German benchmarks.

Q2: What’s the lifespan of your lasers?

A: 100,000+ hours for fiber sources (backed by 5-year warranties—longer than most competitors).

Q3: Are spare parts readily available?

A: Global 48-hour shipping for lenses, diodes, and boards—with 70% lower parts costs than Western brands.

Q4: How rugged are your handheld units?

A: IP54-rated with military-grade shock absorption—tested in shipyards and mining sites.

Q5: Can your systems work 24/7?

A: Yes! Our water-cooled industrial models support continuous operation with <1% power fluctuation.