Durable Continuous Laser Cleaning Machine

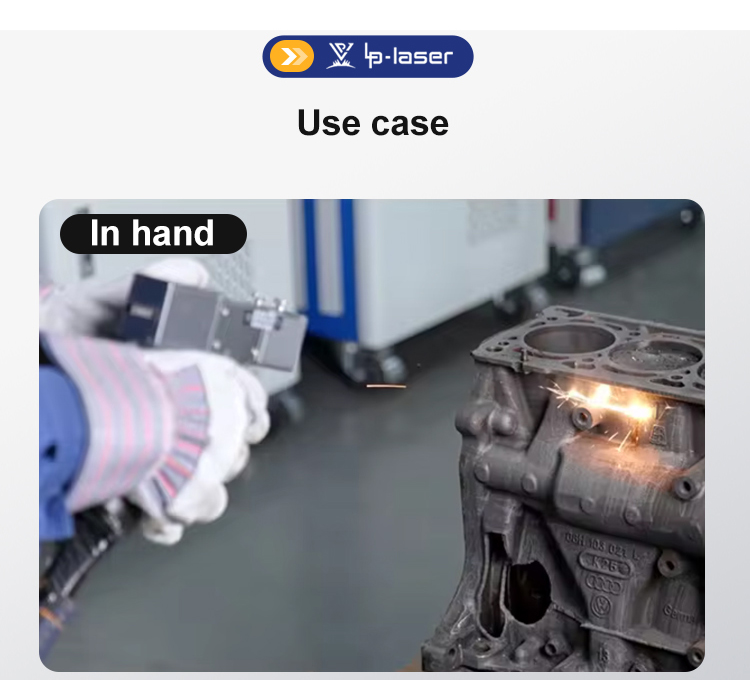

1. Uninterrupted High-Speed Cleaning

Continuous laser operation for seamless cleaning of large surfaces (e.g., pipelines, sheet metal, molds).

2-5X faster than traditional methods (sandblasting/chemical cleaning), maximizing productivity.

2. Superior Precision & Safety

Non-contact process preserves substrate integrity—zero mechanical wear or thermal distortion.

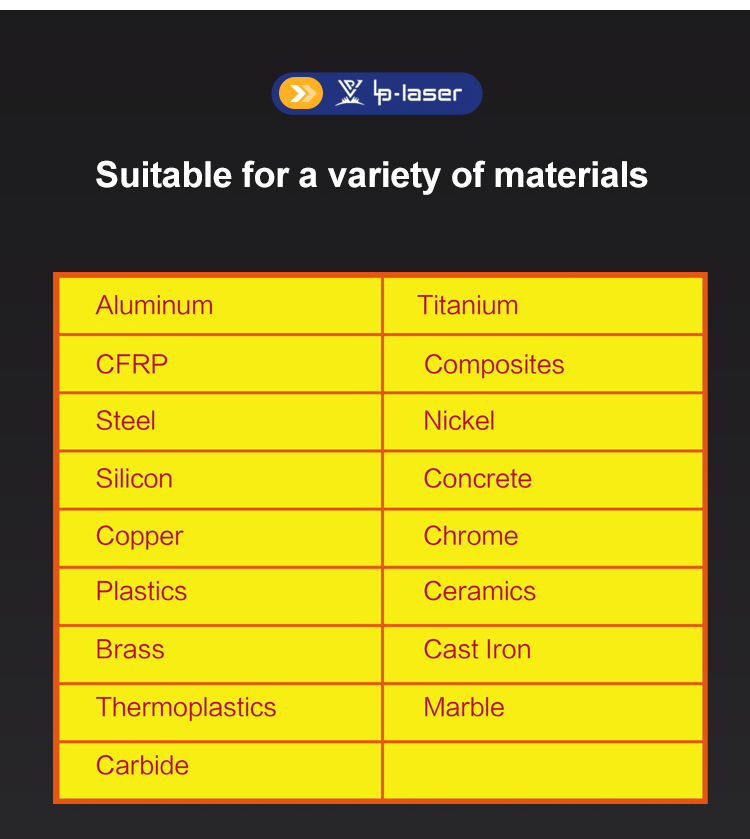

Adjustable power (200W-1000W+) and spot size for versatile materials (steel, aluminum, composites).

3. Eco-Friendly & Cost-Effective

Zero pollutants: No wastewater, toxic chemicals, or consumables (reducing operational costs by up to 60%).

Energy-efficient design with low maintenance requirements.

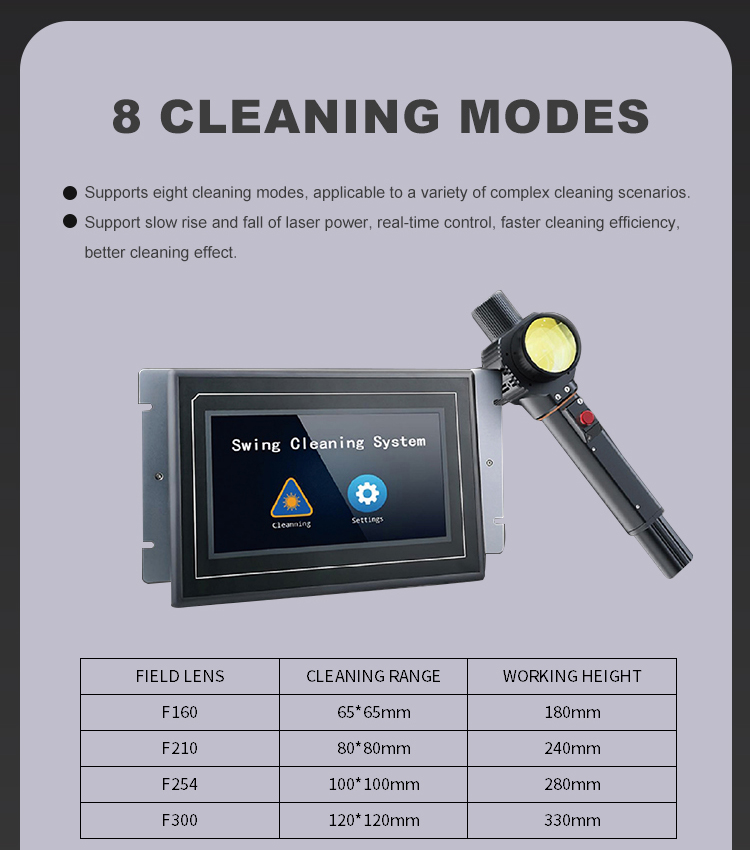

4. Robust & Smart Design

Stable fiber laser source (100,000+ hours lifespan) with IP54 protection for harsh environments.

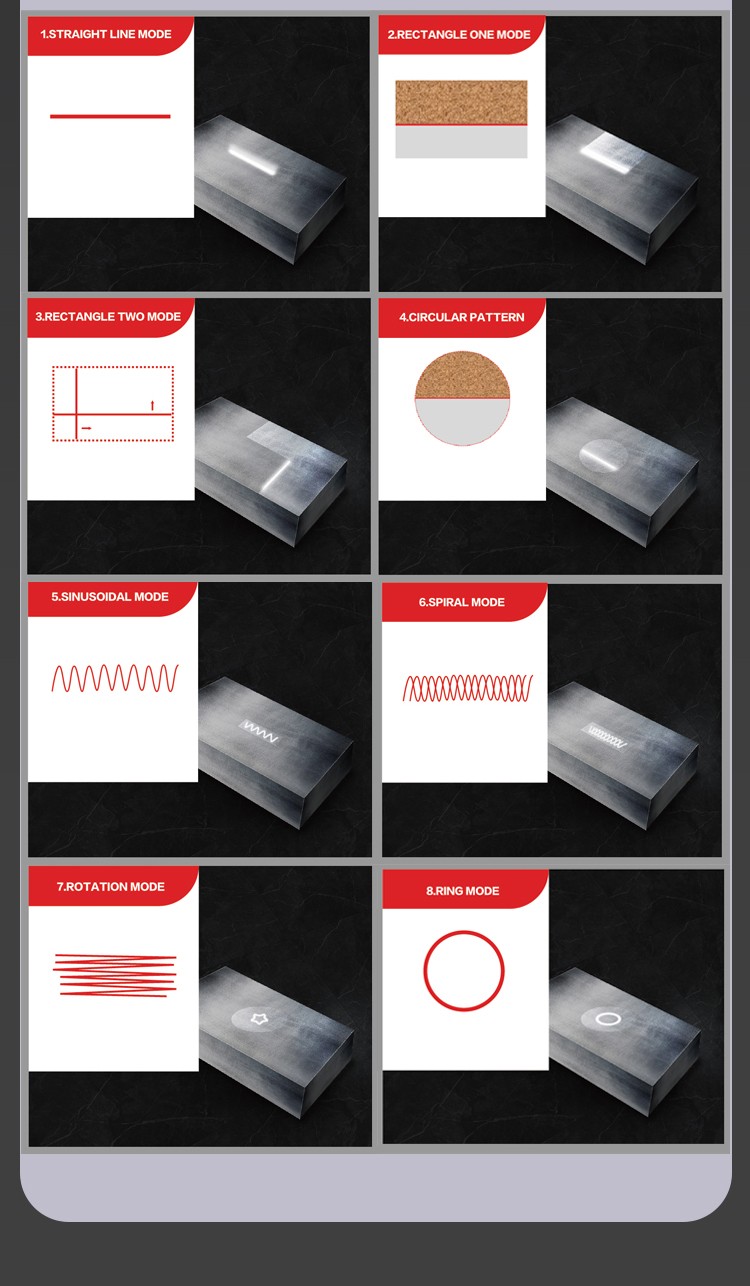

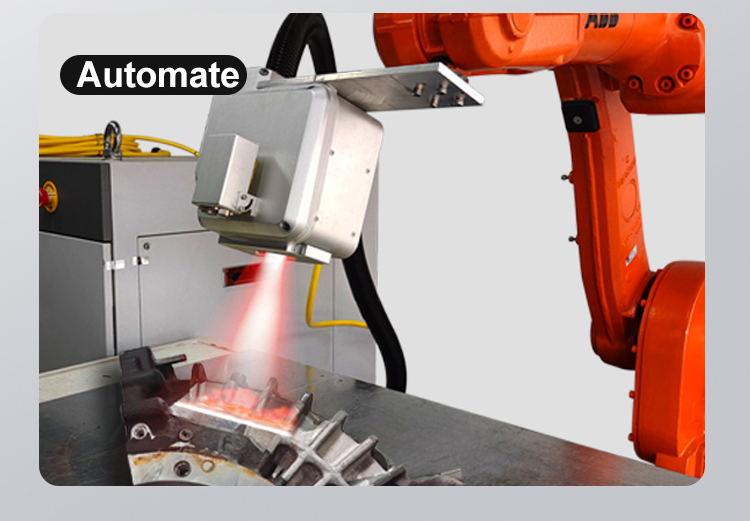

User-friendly interface: Real-time monitoring, automated scanning, and safety interlocks.

5. Customizable Solutions

Tailored configurations (power, scanning width, conveyor integration) for OEM/ODM partners.

Product Overview

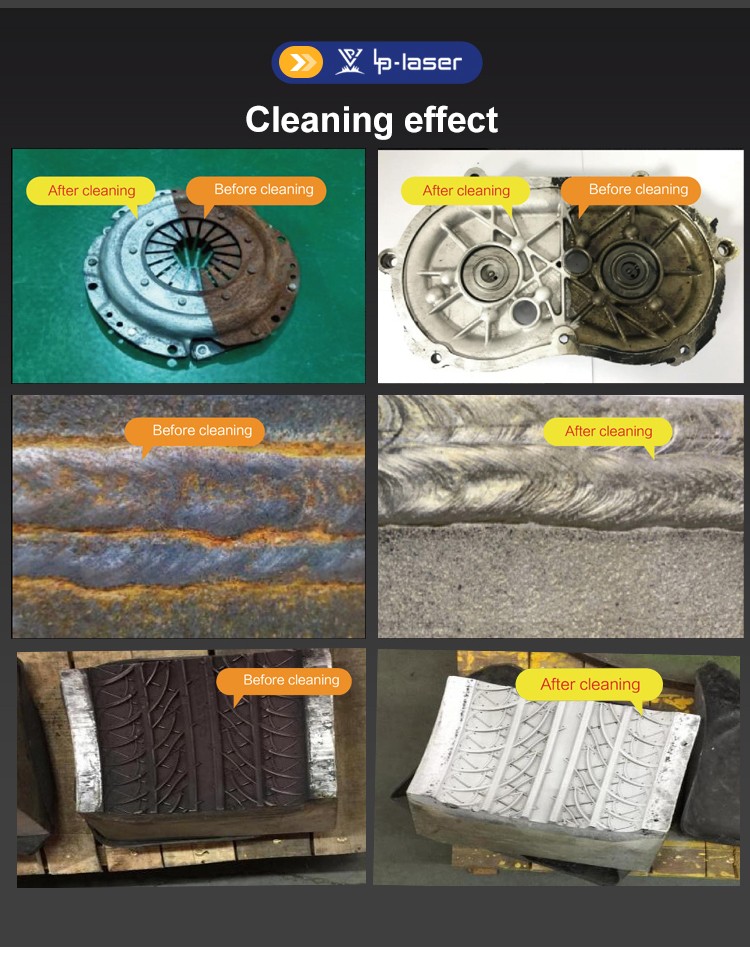

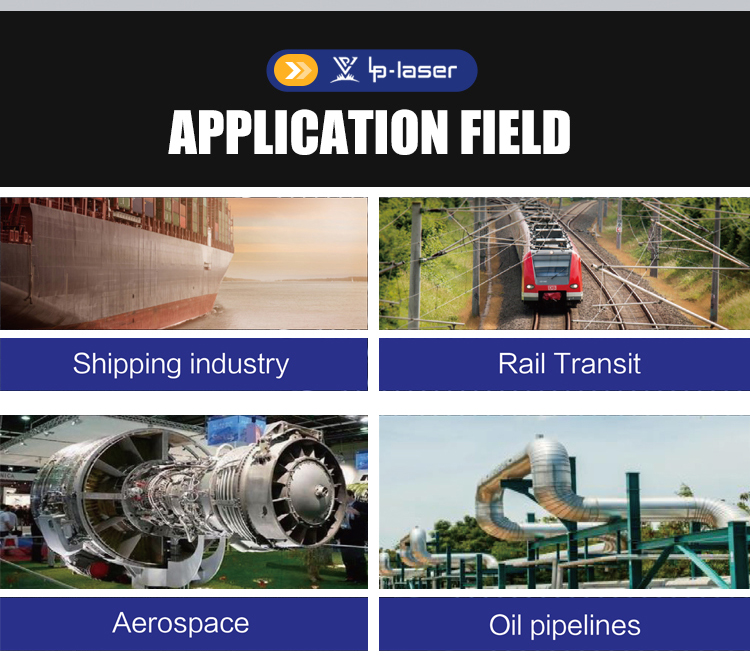

The Continuous Laser Cleaning Machine is an advanced industrial-grade solution designed for high-efficiency, non-contact removal of rust, paint, oxides, coatings, and contaminants from metal surfaces. Utilizing fiber laser technology, it delivers precision cleaning without damaging substrates, making it ideal for automotive, aerospace, shipbuilding, rail maintenance, and cultural heritage restoration.

| Product Model | BLC-1500 | BLC-2000 | BLC-3000 |

| Power | 1500W | 2000W | 3000W |

| Laser wavelength | 1080士10nm | ||

| Fiber mode | Continuous | ||

| Adjustable Frequency Range | 20KHz | ||

| Laser fiber length | 10m (15m can be customized) | 20m | |

| Adjustable widths | 10-160mm | ||

| Voltage | AC220V士10% | AC380V土7% | |

| Total power | 8kw | 10kw | 13kw |

| Cooling mode | Water cooling (deionized water, distilled water or pure water) | ||

| Host size | 845*460*605mm | 905*480*630mm | 1240*584*1148mm |

| Package Size | 1120*565*1050mm | 1430*720*1220mm | |

| Net weight | 113kg | 137kg | 225kg |

| Gross weight | 145kg | 169kg | 285kg |

| Tank capacity | 16L (need to add water 14-15L) | ||