Backpack Laser Cleaning Machine

1.Portability: The primary feature of a backpack laser cleaning machine is its portability. It is lightweight and ergonomically designed to be worn comfortably on the operator's back, allowing for easy movement and access to various locations.

2.Wireless Operation: Many backpack laser cleaning machines are equipped with a battery pack, enabling wireless operation without the need for a power cord. This further enhances mobility and flexibility.

3.Adjustable Laser Parameters: The machine typically allows the operator to adjust laser parameters such as power, frequency, and spot size to suit different cleaning tasks and materials.

4.Safety Features: Safety is a priority, and these machines often include features such as eye protection for the operator, safety interlocks, and sensors to ensure that the laser is only activated when it is safe to do so.

How Backpack laser cleaning machine works?

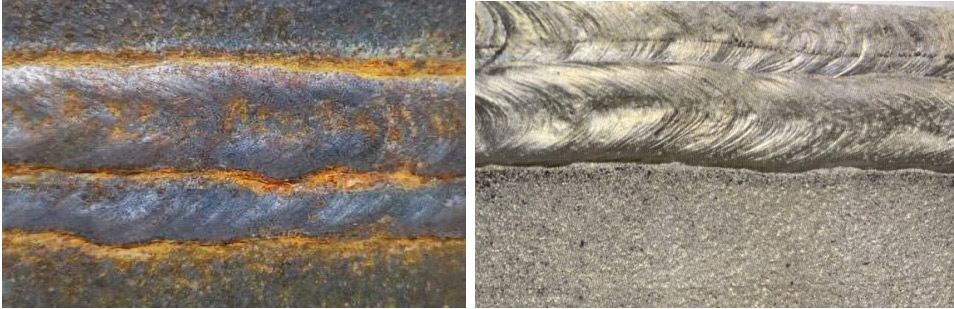

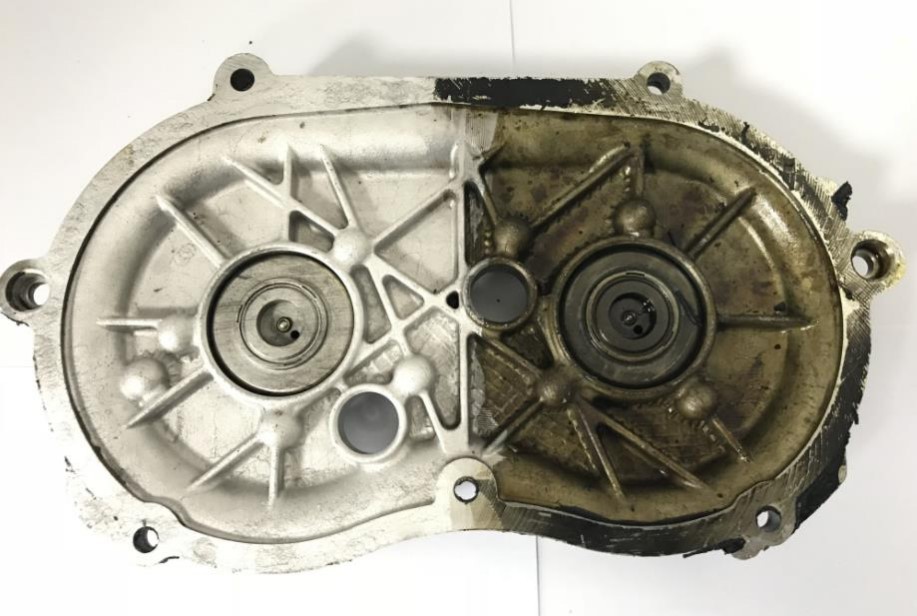

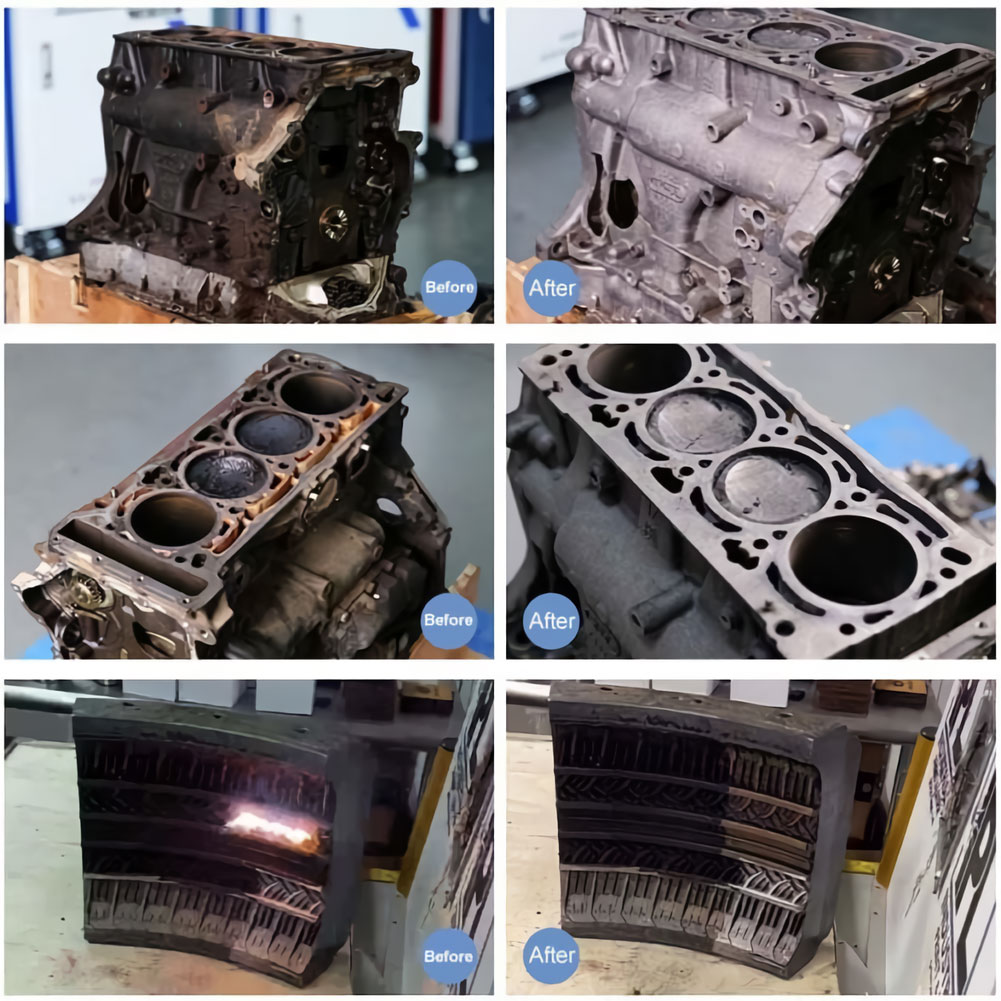

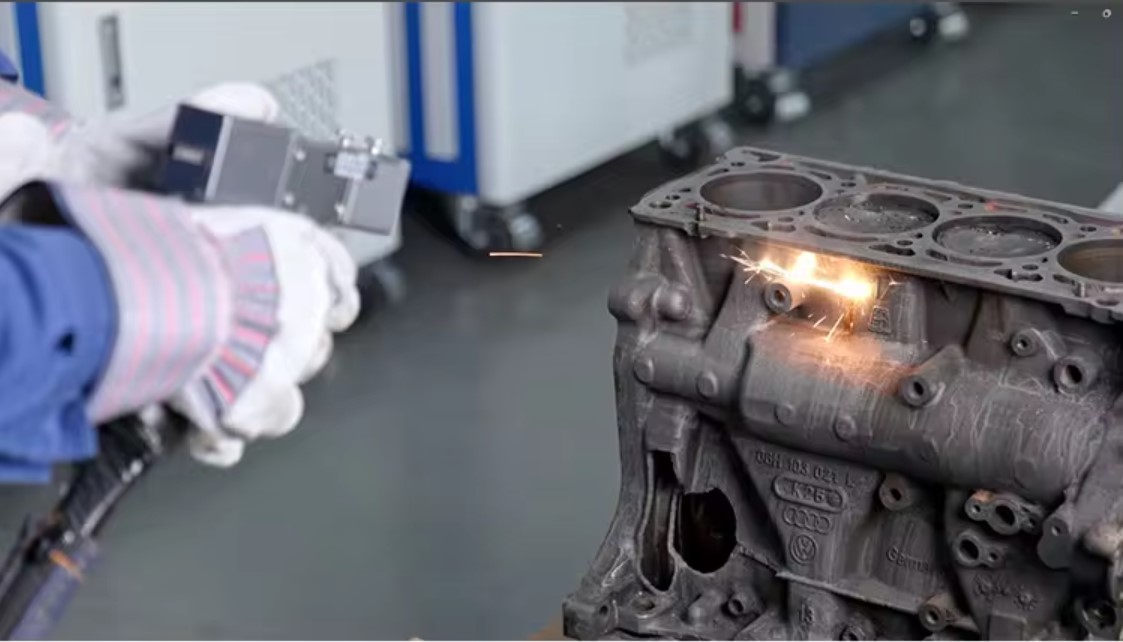

The Backpack laser cleaning machine uses laser rays for cleaning not only moulds and dies, but also for all kinds of workpieces in the process. The success of laser cleaning as an alternative to conventional cleaning methods is due to the many advantages of this process. On the one hand, it does not require cleaning agents or the disposal of residual waste, and therefore has very low operating costs. On the other hand, it is very precise and protects the surface. Above all, the use of laser rays achieves excellent cleaning results. All kinds of oxides, dust particles and especially impurities formed by polymer lubricants, which are very difficult to remove, can be evaporated by the laser in a matter of seconds. The laser-cleaned surfaces are ideally suited for further processing, such as laser welding.

Sample Photos:

Product Parameter:

Model: | HLC-P100W-06D | HLC-P200W-06D | HLC-P300W-06D |

Strip Rate Per Hour: | 24 ft²/hour | ||

Operational Voltage: | 220V±10%、50/60Hz Optional battery, 80-90 minutes of continuous operation | ||

Temperature: | 5℃ ~40℃ | ||

Humidity: | 30-85% Non-Condensing | ||

Power dissipation: | ≤600W | ≤800W | ≤1100W |

Power Output: | 100W | 200W | 300W |

Laser Type: | Fibre | ||

Maximum Pulse Energy: | 1.7mJ | 2mJ(Optional 5mJ) | 2.0mJ(5mJ-15mJ available) |

Pulse Frequency Range: | 20-200kHz(Gradient adjustable) | 1-3000kHz(Gradient adjustable) | 1-3000kHz(Gradient adjustable) |

Pulse Width: | 150-190ns tunable | 13-500ns tunable | 13-500ns tunable |

Output Power Instability: | <5% | ||

Wavelength: | 1064 nm | ||

Head Cable Length: | 1.5 m | 1.5 m | 1.5 m |

Cooling: | Air cooling | ||

Focus Distance: | 160mm | 210mm | 210mm |

Scanning mode: | Dual-axis; supports 9 scanning modes | ||

Head Weight: | ≤0.9Kg | ||

Size W x H x D: | 213mm*123mm*339mm(Battery not included) | 268mm*135mm*445mm(Battery not included) | |

213mm*168mm*339m(Battery included) | 268mm*191.5mm*445mm(Battery included) | ||

Box Dimensions | About 860*840*340mm | ||

Entire Unit Weight: | About 8.5Kg(Battery not included) About 12Kg(Battery included) | About 12.5Kg(Battery not included) About 17Kg(Battery included) | About 13.47 Kg(Battery not included) About 18.08 Kg(Battery included) |

Packed weight: | About 42.1Kg(Battery not included) About 45.3Kg(Battery included) | About 49.9Kg(Battery not included) About 55.3Kg(Battery included) | About 51 Kg(Battery not included) About 56 Kg(Battery included) |

Operation Mode: | Handheld/Automation | ||

Safety Class: | Level IV | ||

Application:

Use Cases:

FAQ:

Q1: Can you customize lasers for niche industries?

A: We’ve built systems for nuclear decontamination, antique restoration, and EV battery cleaning—all with 2-4 week lead times.

Q2: Do you offer OEM/ODM services?

A: Yes! 60% of our clients rebrand our machines—we adjust power, software, and housings to match your market needs.

Q3: How scalable are your solutions for factories?

A: From 50W handhelds to 6kW robotic lines, we support volume orders with 30-day mass production turnaround.

Q4: Can you integrate with existing automation?

A: Our lasers plug into Fanuc, KUKA, and ABB robots via pre-configured interfaces (saving 80% integration time).

Q5: Do you provide application testing?

A: Free sample cleaning reports with before/after microscopy—we’ll optimize settings for your exact material.