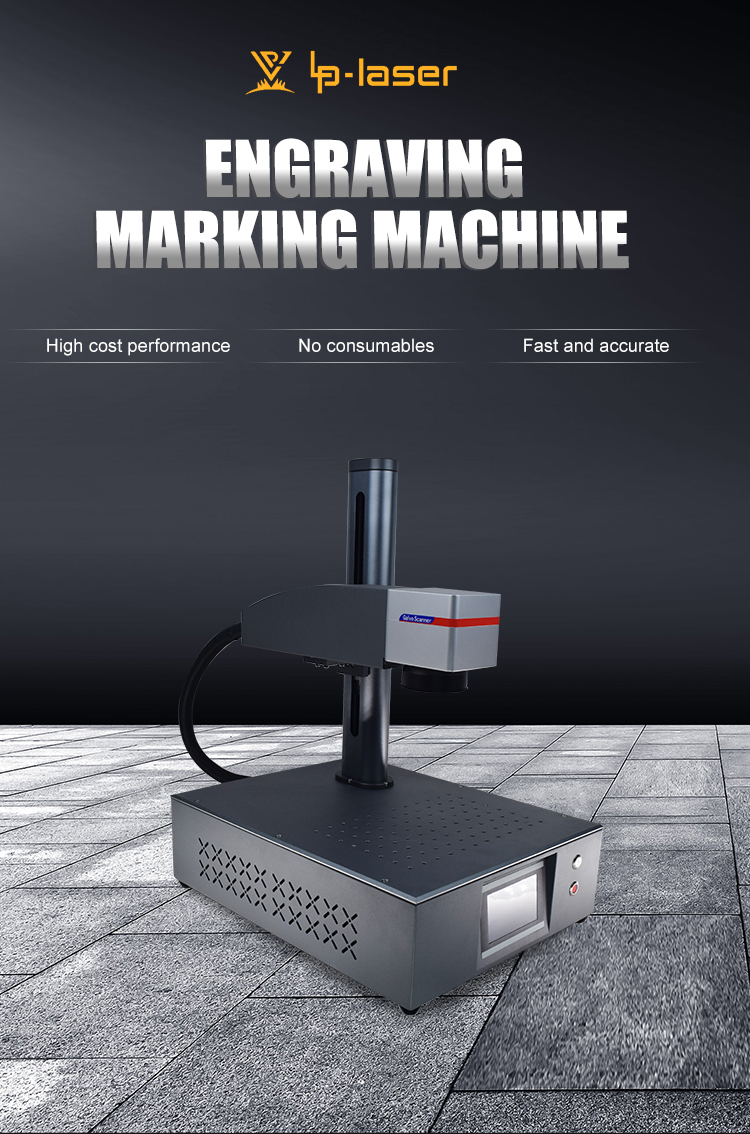

Cheap Engraving Marking Machine

1.High Marking Precision

Fine Details: It can achieve extremely high precision, capable of engraving very small characters and intricate patterns. For instance, it can engrave text with a font size as small as 1mm with clear edges and smooth lines.

Accurate Positioning: With advanced control systems and positioning mechanisms, the engraving machine can ensure that the markings are in the exact position as designed, with a positioning accuracy that can reach micron levels.

2.Excellent Marking Quality

Permanent and Durable: The markings made by the engraving machine are highly resistant to wear, fading, and corrosion. They can remain clear and intact for a long time, even in harsh environmental conditions, ensuring the long-term effectiveness of the markings.

High Contrast and Aesthetics: It can produce markings with high contrast, making the marked information stand out clearly. Whether it's a simple logo or a complex artistic pattern, it can present a high-quality visual effect.

3.Wide Material Applicability

Versatile Material Compatibility: It can work on a wide variety of materials, including metals such as steel, aluminum, copper, and titanium, as well as non-metals like plastics, ceramics, glass, wood, and leather.

Customizable for Different Materials: Different materials can be processed by adjusting the parameters of the engraving machine, such as laser power, engraving speed, and cutting depth, to achieve the best engraving effect.

4.High Efficiency and Productivity

Fast Engraving Speed: The engraving speed is relatively high. For example, a laser engraving machine can complete an engraving task of a simple pattern within a few seconds, which greatly improves the production efficiency, especially in mass production scenarios.

Continuous Operation: With good stability, the engraving machine can work continuously for a long time, reducing downtime and increasing overall productivity.

5.Flexible Operation and Customization

User-Friendly Software: The engraving machine is equipped with dedicated software that allows users to easily design and edit marking content, import graphics and text in various formats, and adjust parameters such as engraving depth and speed according to their needs.

Customizable Marking: It can meet different customization requirements, such as marking serial numbers, barcodes, QR codes, and personalized patterns, to meet the specific needs of different industries and customers.

Product Introduction

The Engraving Marking Machine is a device specifically designed to create permanent and precise markings on the surfaces of various materials. It utilizes different technologies like laser, mechanical, or chemical methods to etch, carve, or cut patterns, characters, logos and other information onto the material surface.

For example, the laser engraving marking machine projects a high-energy laser beam onto the material surface. The heat from the laser beam vaporizes or melts the material in the targeted area, forming clear and accurate marks. Mechanical engraving marking machines, on the other hand, usually use a rotating cutter or stylus to remove material from the surface to create the markings. Chemical engraving marking machines use chemical reactions, such as etching with acid or other corrosive substances, to create patterns on the material surface.

Key Features:

✔ Multi-Technology Options – Choose from laser engraving (fiber/CO₂/UV), dot peen marking, or rotary engraving.

✔ Wide Material Compatibility – Works on steel, aluminum, brass, PVC, acrylic, leather, and more.

✔ Precision Control – Achieve fine details (up to 0.01mm resolution) for logos, text, or barcodes.

✔ User-Friendly Software – Compatible with AutoCAD, CorelDraw, and proprietary marking software.

✔ Low Maintenance & Cost-Effective – No consumables (inks/tools) required for laser models.

✔ High-Speed Operation – Mark hundreds of parts per hour with automated feeding options.

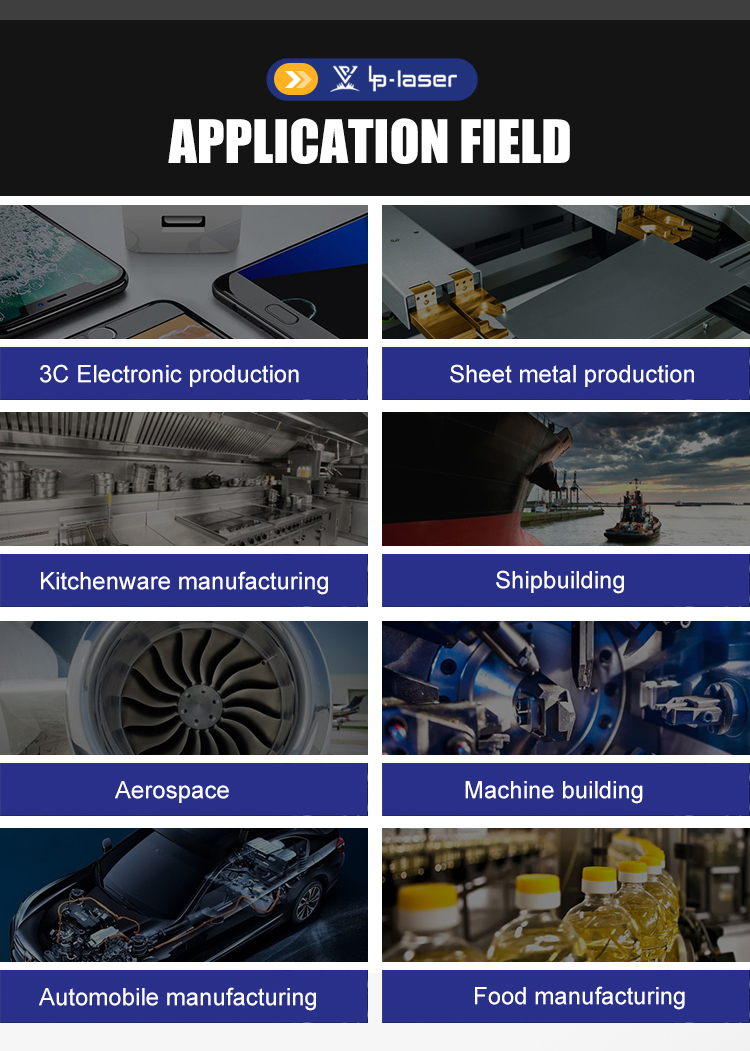

Applications:

Industrial Part Numbering & QR Codes

Custom Jewelry & Awards Engraving

Electronic Components & PCB Marking

Medical & Surgical Instrument Identification

Promotional Items & Personalized Gifts

Why Choose Our Engraving & Marking Machine?

✅ Durable & Long-Lasting Marks – Resistant to heat, abrasion, and chemicals.

✅ Flexible Solutions – Adjustable depth/force for delicate or heavy-duty materials.

✅ Eco-Friendly Process – No waste, fumes, or hazardous byproducts (laser models).

✅ 24/7 Reliability – Designed for continuous production environments.

| Laser Type | Fiber Laser |

| Power | 20w/30w/50w |

| Laser Source Brand | MAX/RAYCUS JPT MOPA Optional |

| Marking Area | 70*70mm/110*110mm/150*150mm |

| Minimun Line Width | 0.01mm Depends on the material |

| Minimum Character | 0.2mm Depends on the material |

| Language | Chinese, Korean, Japanese, German, French, Arabic. Spanish,Portuguese, Vietnamese, Farsi, Russian, Thai. etc. |

| Cooling Mode | Air Cooling |

| Net weight | 20kg |

1.Q: Do fiber marking machines offer good value for small - scale production?

A: Yes. Although they are often associated with large - scale production, their flexibility and efficiency also make them a good choice for small - scale production. The fast marking speed can quickly handle small batches, and the customization features can meet diverse product requirements.

2.Q: How does the wide material adaptability of fiber marking machines affect their cost - effectiveness?

A: The ability to mark various materials means that one fiber marking machine can replace multiple specialized marking machines for different materials. This reduces the initial investment and long - term maintenance costs.

3.Q: Are there additional costs when marking different materials with a fiber marking machine?

A: Generally, there are no significant additional costs. The machine can adjust its parameters for different materials without the need for major hardware changes. However, in some cases, special marking fluids or fixtures might be required, but these are usually minimal expenses.