High Quality Handheld Laser Rust Removal Machine

High Precision

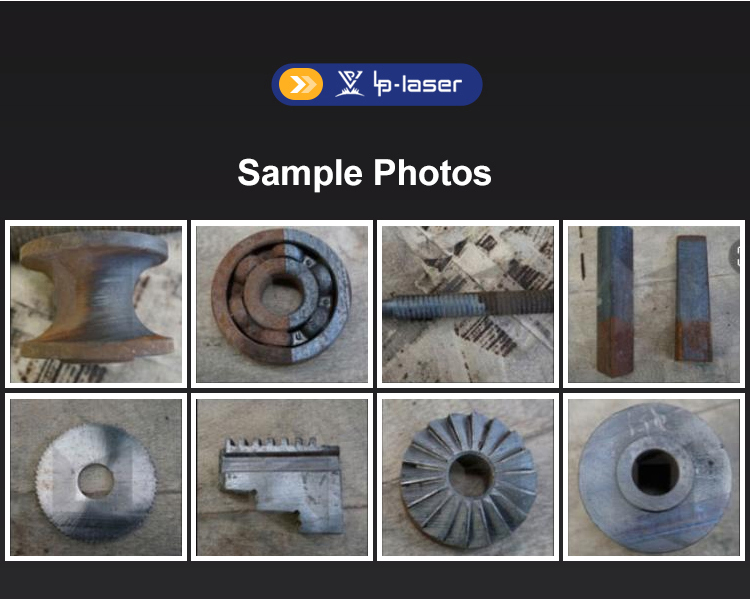

One of the standout features of the handheld laser rust removal machine is its exceptional precision. The laser beam can be focused to a very small spot size, allowing operators to target rust in the most intricate and hard - to - reach areas. Whether it's cleaning rust from the corners of a small mechanical part or delicate components in electronics, the machine ensures that only the rust is removed, without causing any collateral damage to the surrounding healthy metal. This precision is crucial for maintaining the integrity and functionality of the workpiece, especially in industries where even the slightest scratch or damage can be costly.

Non - Contact Cleaning

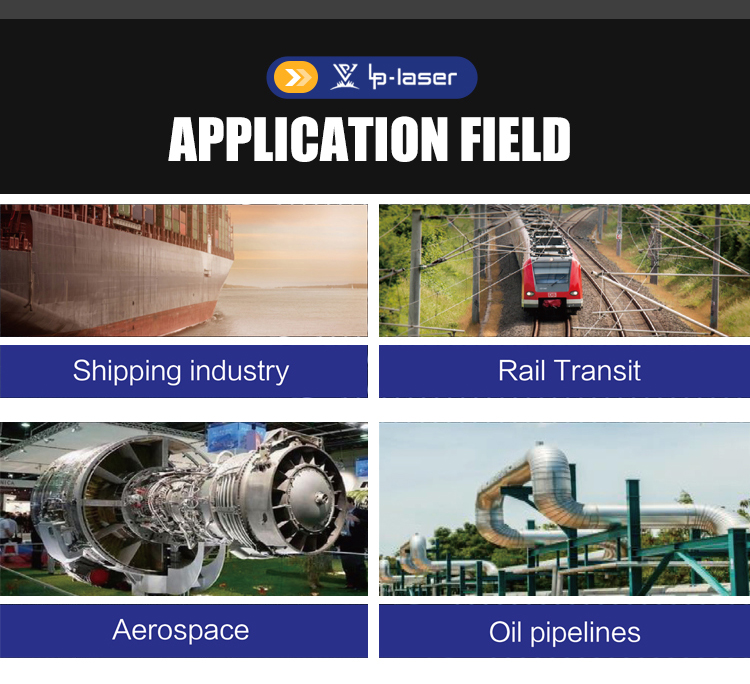

Unlike traditional rust - removal methods that rely on abrasive tools like sandpaper, wire brushes, or chemical solvents, the handheld laser rust removal machine cleans surfaces without any physical contact. This non - contact nature of operation eliminates the risk of mechanical damage such as scratches, dents, or deformations that are common with abrasive techniques. It is particularly beneficial for metals with soft textures, thin - walled components, or those with high - precision surface requirements. For example, in the aerospace industry, where parts are made of lightweight and often delicate metals, the non - contact laser cleaning method ensures that the structural integrity and surface finish of the components are preserved.

Environmentally Friendly

In an era of increasing environmental awareness, the handheld laser rust removal machine stands out as an eco - friendly alternative. It does not require the use of water, harsh chemicals, or abrasive materials, which are commonly used in traditional rust - removal processes. Traditional methods often produce wastewater contaminated with chemicals or generate dust pollution, both of which can have negative impacts on the environment and human health. In contrast, the laser cleaning process produces only a small amount of vaporized rust and some particulate matter. These by - products can be easily managed with proper ventilation and filtration systems, making the handheld laser rust removal machine a sustainable choice for rust removal.

High Efficiency

Equipped with powerful laser sources, these handheld machines can clean rust - covered surfaces at an impressive speed. The high - energy laser beam acts quickly on the rust, accelerating the removal process. Compared to manual rust - removal methods that involve labor - intensive scrubbing or scraping, or traditional mechanical cleaners that may require disassembly of parts, the handheld laser rust removal machine can cover large areas in a relatively short time. In industrial settings, where time is of the essence, this high efficiency significantly reduces the time spent on rust - removal tasks, leading to increased productivity. For instance, in a manufacturing plant where metal parts need to be cleaned before further processing, the use of a handheld laser rust removal machine can streamline the production line by quickly preparing the parts for painting, welding, or other finishing operations.

Cost - Effective in the Long Run

Although the initial investment in a handheld laser rust removal machine may seem relatively high compared to some basic traditional rust - removal tools, it offers long - term cost savings. There is no need to constantly purchase and replace consumables such as abrasive media, chemical solvents, or brushes. The machine is also energy - efficient, consuming less power compared to some traditional cleaning equipment. Additionally, by minimizing the risk of damaging the metal workpiece during cleaning, it reduces the cost of rework and replacement. In the long term, these factors contribute to a lower overall cost of operation, making the handheld laser rust removal machine a cost - effective solution for businesses.

User - Friendly Operation

Most handheld laser rust removal machines are designed with user - friendliness in mind. They typically feature intuitive control panels or interfaces that allow operators to easily adjust parameters such as laser power, pulse duration, and scanning speed according to the specific rust - removal requirements. Even those with little prior experience can quickly learn to use the machine effectively after a short training period. The lightweight and ergonomic design of the handheld unit also ensures comfortable handling during operation, reducing operator fatigue during extended use. This simplicity in operation not only reduces the need for highly skilled labor but also ensures consistent and reliable rust - removal performance.

Handheld Laser Rust Removal Machine Introduction

In the realm of surface cleaning, the handheld laser rust removal machine has emerged as a revolutionary tool, catering to a wide range of industries and applications. This compact yet powerful device is designed to offer an efficient, precise, and environmentally friendly solution for rust removal.

Working Principle

The machine operates on a simple yet highly effective principle. It emits a high - energy laser beam. When this beam makes contact with the rust layer on a metal surface, the rust rapidly absorbs the laser energy. The energy causes an immediate temperature rise in the rust, leading to its vaporization or ablation. In some cases, the intense heat also generates a shockwave, which aids in detaching the rust from the underlying metal substrate. This process is made possible by the unique optical and thermal properties of the laser, ensuring that only the rust is affected, while the base metal remains intact.

| Laser power | 1500W/2000W/3000W |

| Laser Wavelength | 1080±10nm |

Output power Instability | <2% |

| Output Power Tunability | 10-100% |

| Cooling Way | Water-cooling |

| Cooling medium | Purified water, distilled water, high-purity water |

| Working Environment Requirements | 0℃~40℃, humidity<70% |

| Voltage | 220V/380V/Customized |

| Cleaning Width | 40mm |

| Mode of operation | In hand |

Q1: What exactly is laser cleaning?

A: A non-abrasive process using focused laser light to remove contaminants through precise ablation without damaging the substrate material.

Q2: How does laser wavelength affect cleaning?

A: 1064nm (fiber lasers) works best for metals, while 532nm/355nm are better for organics due to differing absorption rates.

Q3: What's the difference between pulsed and CW lasers?

A: Pulsed (ns/ps) offers precision for delicate work; Continuous Wave provides faster cleaning for industrial-scale jobs.

Q4: Why doesn't it harm the base material?

A: The laser's fluence is calibrated to exceed contaminant ablation thresholds while staying below the substrate's damage threshold.

Q5: Which materials respond best?

A: Metals (steel/aluminum/copper), stone, ceramics, and composites show excellent results with minimal thermal impact.