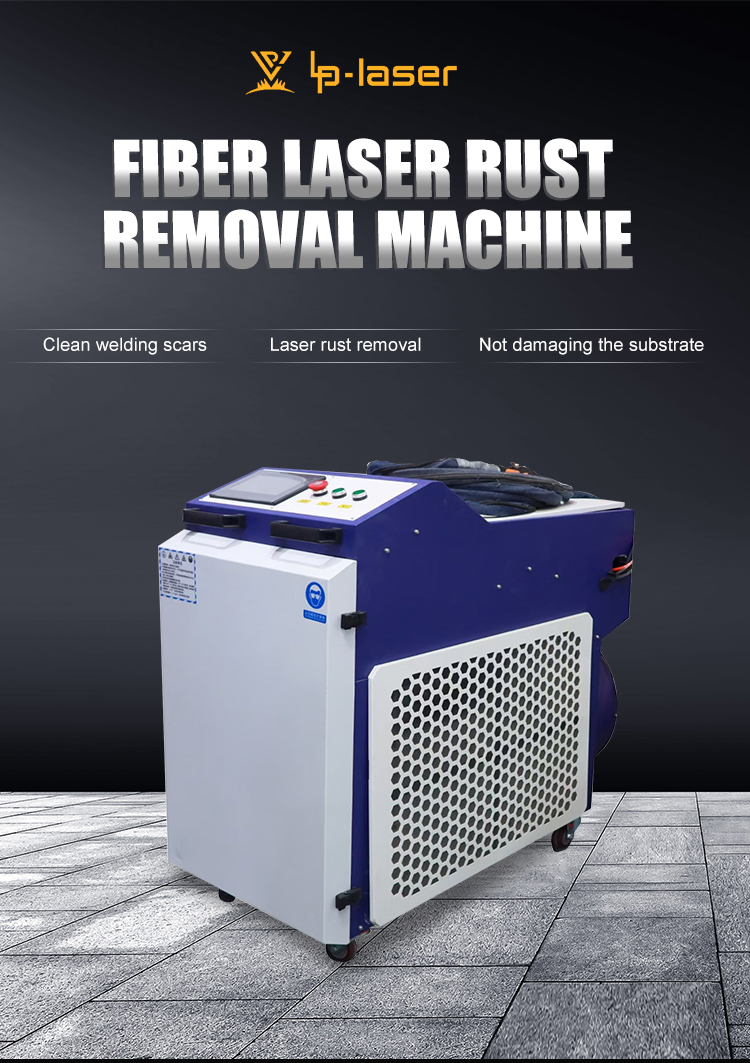

High Quality Fiber Laser Rust Removal Machine

1. High Precision Rust Removal

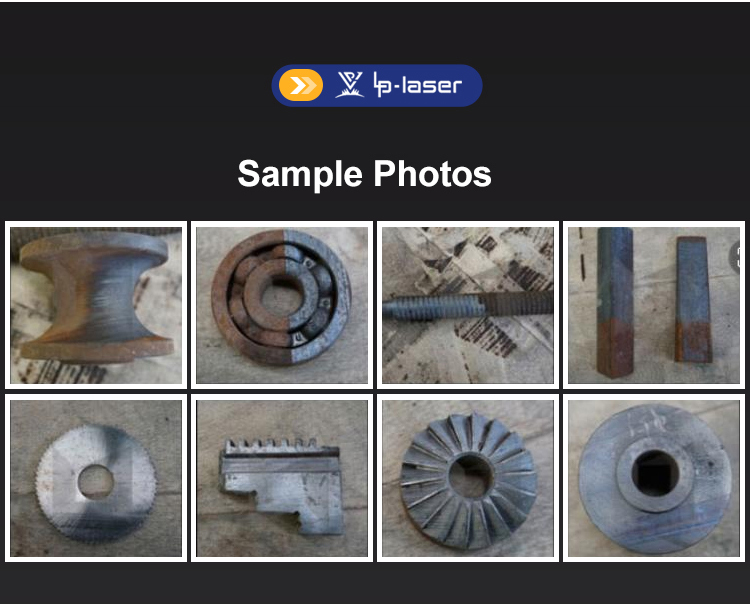

Fiber laser rust removal machines offer unrivaled precision. The laser beam can be focused down to a fine point, allowing it to target rust on metal surfaces with extreme accuracy. Whether dealing with small, intricate metal parts or large industrial components, it can precisely remove rust without affecting the surrounding areas. This precision ensures that even the most delicate metal substrates remain intact, which is crucial for maintaining the integrity and functionality of the workpiece.

2. Non - Contact Cleaning

These machines clean via a non - contact method. The high - energy laser beam acts on the rust from a distance, vaporizing or ablating it without any physical contact with the metal. This eliminates the risk of mechanical damage such as scratches, dents, or deformations that are common in traditional abrasive cleaning methods. It's especially beneficial for metals with soft textures or thin - walled components, preserving their original surface finish and properties.

3. Environmentally Friendly

Fiber laser rust removal is an eco - friendly alternative. It doesn't require the use of water, harsh chemicals, or abrasive materials. Traditional cleaning methods often produce wastewater contaminated with chemicals or generate dust pollution, which can be harmful to the environment and human health. In contrast, laser cleaning produces only a small amount of vaporized rust and some particulate matter that can be easily managed with proper ventilation and filtration systems.

4. High Efficiency

Equipped with powerful fiber lasers, these machines can quickly remove rust. The laser beam rapidly heats the rust, causing it to vaporize or flake off. Compared to manual rust - removal methods or some traditional mechanical cleaners, fiber laser machines can cover large areas in a much shorter time. In industrial settings, this high efficiency significantly reduces the time spent on rust - removal tasks, increasing overall productivity.

5. Cost - Effective in the Long Run

Although the initial investment in a fiber laser rust removal machine might be relatively high, it offers long - term cost savings. There's no need to constantly purchase and replace consumables like abrasive media or cleaning chemicals. The machines are also energy - efficient, consuming less power compared to some traditional cleaning equipment. Additionally, by minimizing the risk of damaging the metal workpiece during cleaning, they reduce the cost of rework and replacement.

6. Versatile Application

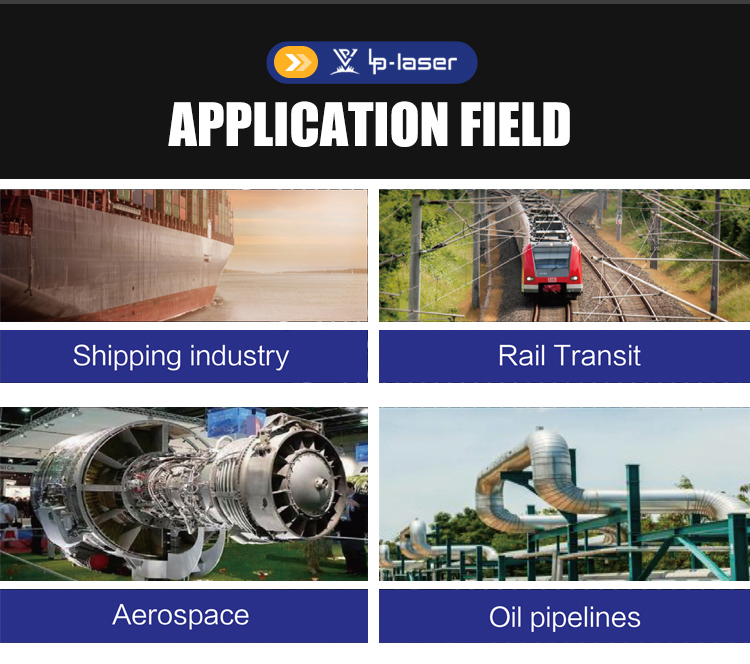

Fiber laser rust removal machines can be used on a wide range of metal materials, including steel, aluminum, copper, and their alloys. They are effective in removing not only rust but also other contaminants such as paint, oil, and oxide layers. This versatility makes them suitable for various industries, from automotive manufacturing and aerospace to shipbuilding and metal fabrication.

7. Precise Control and Customization

Operators can precisely control the laser parameters such as power, pulse duration, and frequency according to the specific rust - removal requirements. This allows for customized cleaning based on the type of metal, the thickness of the rust layer, and the surface finish desired. Whether it's a light rust - removal task on a highly polished metal surface or a more intensive cleaning of heavily rusted industrial equipment, the machine can be adjusted to achieve optimal results.

8. Easy to Integrate and Automate

These machines can be easily integrated into existing production lines or automated manufacturing systems. They can be paired with robotic arms or automated positioning systems to perform repetitive rust - removal tasks with high precision and consistency. This automation not only improves the quality of the cleaning process but also reduces the need for human labor in potentially hazardous or monotonous rust - removal operations.

product introduction

Fiber laser rust removal machines are revolutionizing the field of surface cleaning in various industries. These advanced devices utilize the power of fiber - optic - delivered laser beams to effectively and efficiently eliminate rust from metal surfaces.

Working Principle

The machine emits a high - energy laser beam. When this beam strikes the rust layer on the metal surface, it is rapidly absorbed by the rust. The energy causes the rust to heat up instantaneously. This sudden heating leads to the vaporization or ablation of the rust, breaking it down into tiny particles that are then easily removed. In some cases, the intense heat also creates a shockwave that helps in detaching the rust from the underlying metal substrate.

| LASER POWER | 1500W/2000W/3000W |

| Fiber Cable | 20M |

| Wavelength | 1070nm |

| Scan Speed | 0-7000mm/s |

Cooling Way | Water-cooling |

| Laser source type | Fiber Continous |

| key selling points | Easy to Operate |

Q1: Typical ROI period?

A: 8-18 months by eliminating media costs (e.g., shipyard saves $200k/year).

Q2: Cost per square meter?

A: $0.15-$1.20/m² (vs. $3-$8 for sandblasting).

Q3: Leasing options?

A: Available – e.g., $1,800/month for 200W systems (36-month term).

Q4: Most cost-effective application?

A: High-value part restoration (e.g., aircraft components at $300/hr labor savings).

Q5: Hidden costs?

A: Training ($2k/operator) and facility upgrades (electrical/ventilation).