Portable Laser Cleaning Machine

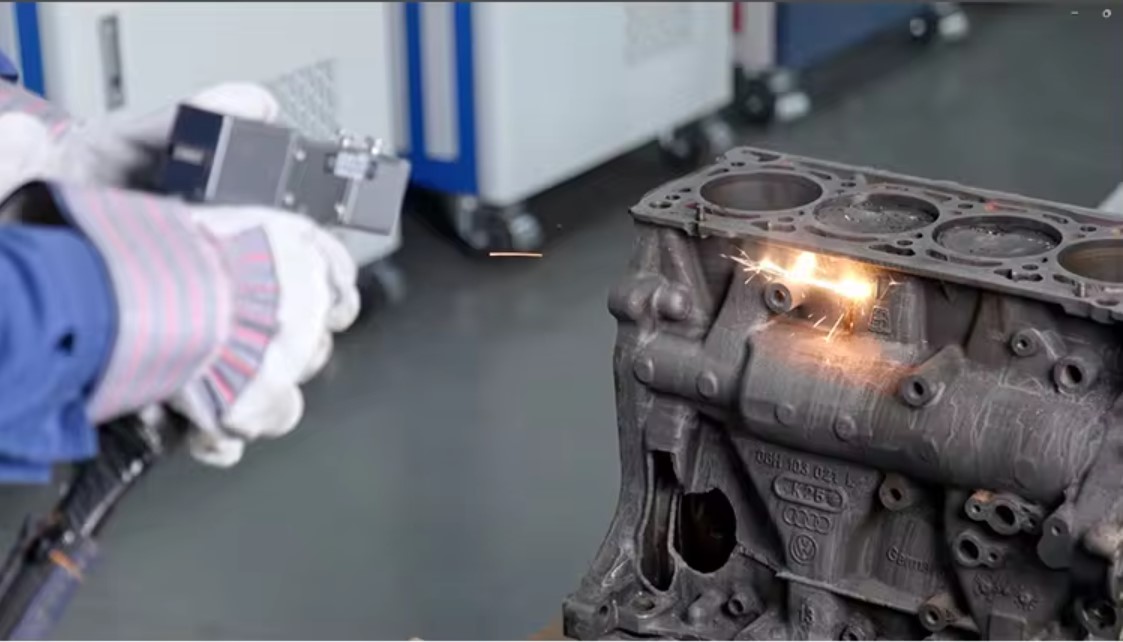

1.Mobility: Portable laser cleaning machines are designed to be lightweight and easy to move, often equipped with handles or wheels for convenient transportation.

2.Ease of Use: These machines typically have user-friendly interfaces with simple controls, allowing operators to quickly set up and start the cleaning process.

3.Non-Contact Cleaning: The laser cleaning process does not require physical contact with the surface, which helps to prevent damage to the substrate and ensures a gentle yet effective cleaning method.

4.Adjustable Parameters: Many portable laser cleaning machines offer adjustable settings for laser power, pulse frequency, and spot size, enabling customization for different materials and levels of contamination.

5.High Precision: The laser beam can be precisely controlled, allowing for detailed cleaning of intricate areas without affecting the surrounding material.

How Portable Laser Cleaning Machine Works?

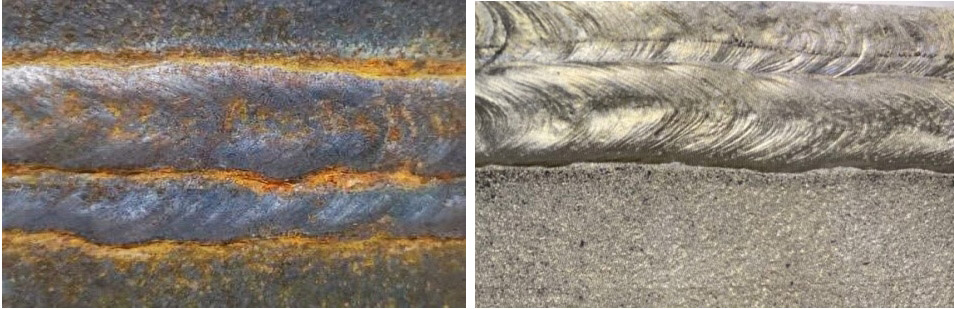

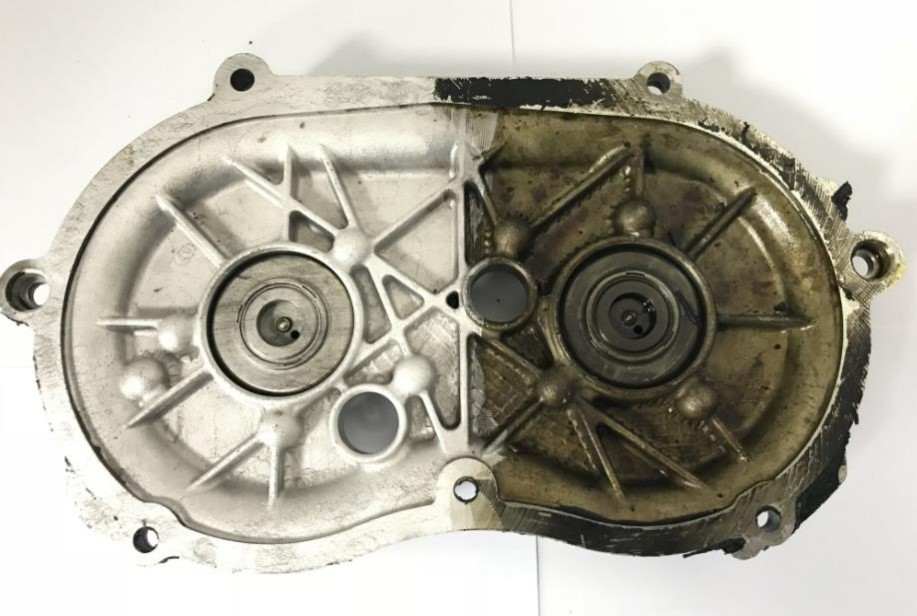

The Portable Laser Cleaning Machine uses laser rays for cleaning not only moulds and dies, but also for all kinds of workpieces in the process. The success of laser cleaning as an alternative to conventional cleaning methods is due to the many advantages of this process. On the one hand, it does not require cleaning agents or the disposal of residual waste, and therefore has very low operating costs. On the other hand, it is very precise and protects the surface. Above all, the use of laser rays achieves excellent cleaning results. All kinds of oxides, dust particles and especially impurities formed by polymer lubricants, which are very difficult to remove, can be evaporated by the laser in a matter of seconds. The laser-cleaned surfaces are ideally suited for further processing, such as laser welding.

Sample Photos:

Product Parameter:

Model: | HLC-P200W | HLC-P300W |

Operational Voltage: | 220V±10%、50/60Hz customisable:110V、50Hzalternating current | |

Temperature: | 5℃ ~40℃ | |

Humidity: | 30-85% Non-Condensing | |

Power dissipation: | ≤1500W | ≤1500W |

Power Output: | 200W | 300W |

Laser Type: | Fibre | |

Maximum Pulse Energy: | 2mJ | 2mJ/15mJ |

Pulse Frequency Range: | 1-3000kHz(Gradient adjustable) | 1-3000kHz(Gradient adjustable) |

Pulse Width: | 13-500ns tunable | 13-500ns tunable |

Output Power Instability: | <5% | |

Wavelength: | 1064 nm | |

Head Cable Length: | 3 m | 5 m |

Cooling: | Air cooling | |

Focus Distance: | 210mm | 210mm |

Scanning mode: | Dual-axis; supports 9 scanning modes | |

Head Weight: | ≤0.9Kg | ≤1.25Kg |

Size W x H x D: | About 617mm*469mm*291mm | |

Box Dimensions | About 760mm*560mm*460mm | |

Entire Unit Weight: | About 28Kg | About 29Kg |

Packed weight: | About 28.2Kg | About 49Kg |

Operation Mode: | Handheld/Automation | |

Safety Class: | Level IV | |

Application:

Use Cases:

FAQ:

1. How does a laser cleaning machine help save money in the long run?

Eliminates Consumables: Unlike traditional methods (chemicals, abrasives, sandpaper), it requires no disposable materials, slashing recurring costs.

Low Maintenance: Solid-state laser systems have minimal wear, reducing repair and replacement expenses.

Energy Efficiency: Consumes less power than comparable industrial cleaning systems (e.g., plasma or wet blasting).

Increased Productivity: Faster cleaning speeds minimize labor hours and machine downtime.

Example: A manufacturer switching from chemical cleaning to laser cleaning reported a 40% drop in annual cleaning costs.

2. Is the initial investment in a laser cleaner justified by its cost savings?

Yes—most businesses recover the cost within 1–2 years. Savings come from:

✅ No chemical costs or waste disposal fees

✅ Reduced labor due to automation/semi-automation

✅ Lower reject rates (precise cleaning avoids rework)

✅ Extended tool/machinery life (gentle cleaning prevents damage)

Case Study: An automotive parts supplier recouped their investment in 18 months through reduced chemical use and faster production.

3. Does a laser cleaner consume a lot of energy?

Not significantly. Modern industrial lasers typically use:

5–30 kW (depending on the model and material)

Compare this to 70–200 kW for some plasma systems or continuous water blasting machines.

Additionally, its precision reduces over-cleaning, saving energy further.