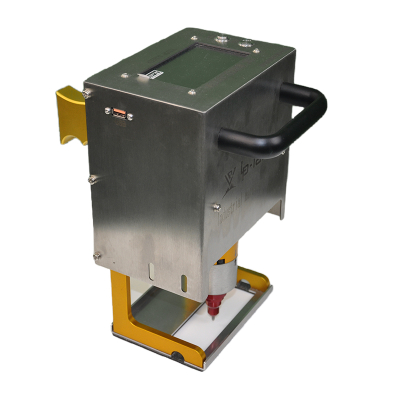

Durable Pulsed Laser Cleaning Machine

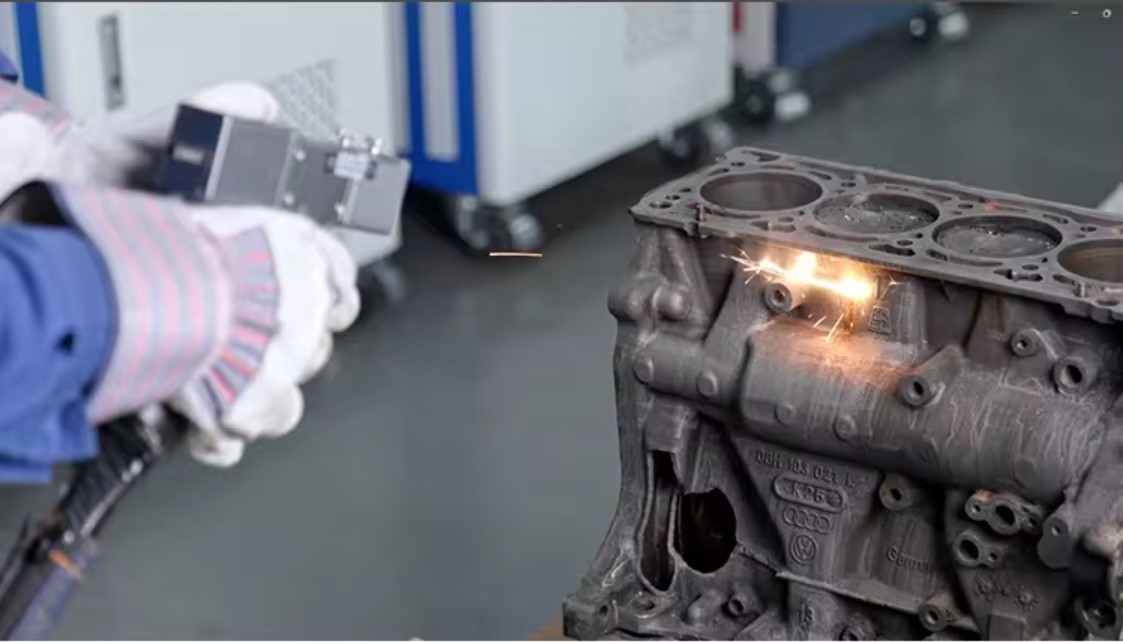

1.Pulsed Laser Beam: The machine emits a series of short, high-energy laser pulses. The energy from these pulses is absorbed by the contaminants, causing them to vaporize or detach from the surface.

2.High Precision: The short duration of the laser pulses allows for very precise cleaning, targeting only the contaminants and leaving the substrate material intact.

3.Adjustable Pulse Parameters: Users can typically adjust the pulse duration, frequency, and energy to tailor the cleaning process to specific materials and levels of contamination.

4.Non-Abrasive Cleaning: The pulsed laser cleaning process is non-contact and non-abrasive, meaning it does not use physical force or chemicals to remove contaminants, which helps to preserve the integrity of the cleaned surface.

5.Versatility: Pulsed laser cleaning machines can be used on a wide range of materials, including metals, ceramics, composites, and even delicate materials like stone and glass.

How Pulsed Laser Cleaning Machine Works?

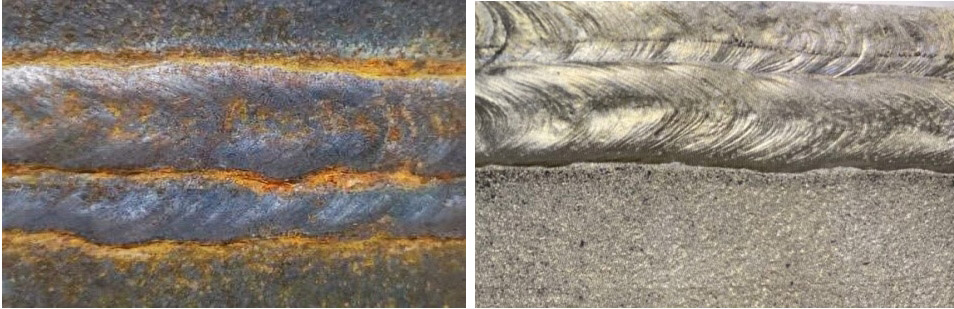

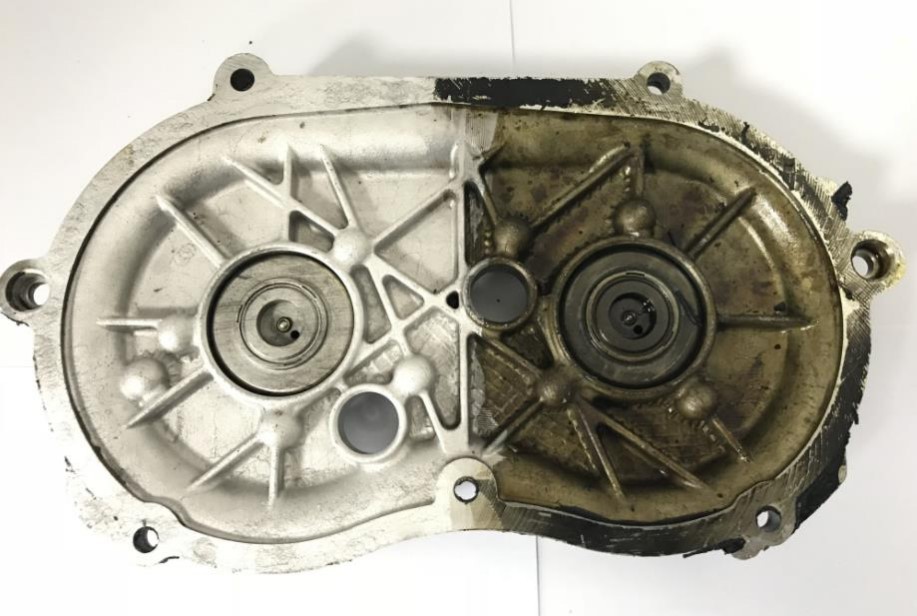

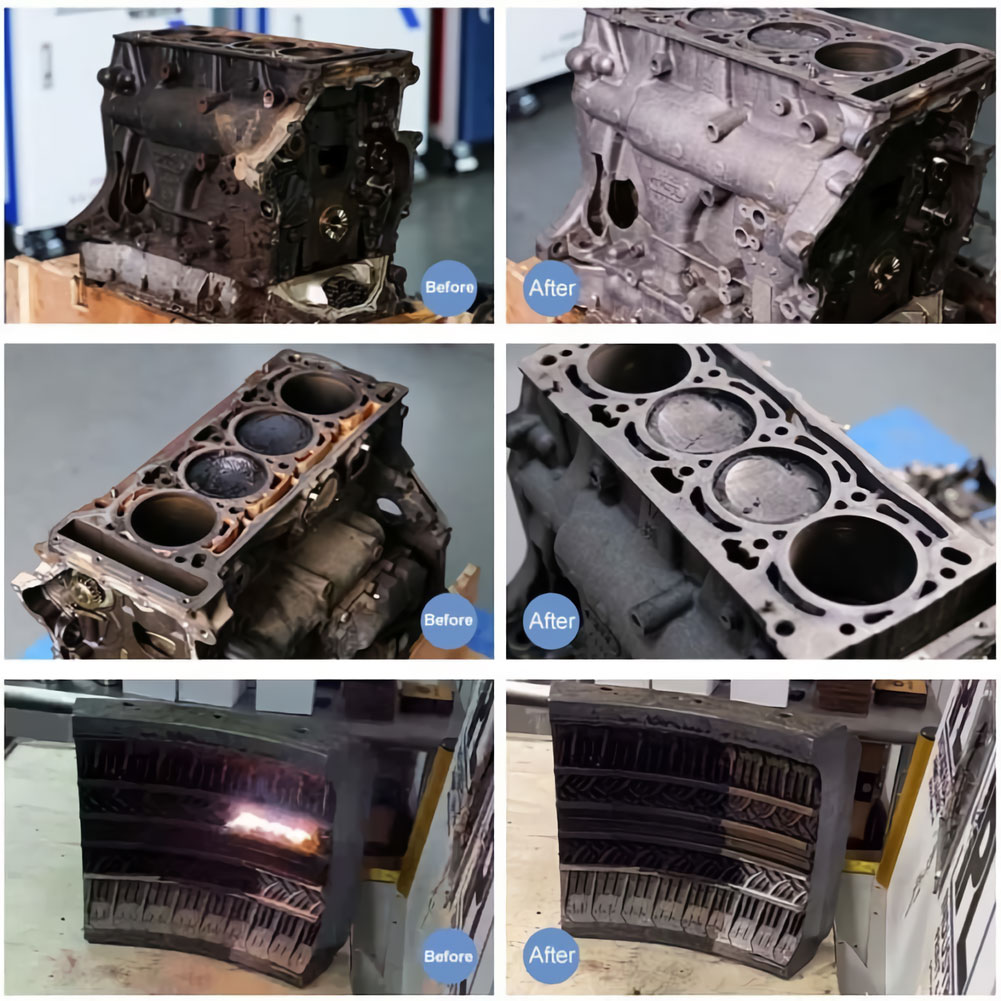

The Pulsed Laser Cleaning Machine uses laser rays to clean not only moulds and dies, but also all kinds of workpieces in the process. The success of laser cleaning as an alternative to conventional cleaning methods is due to the many advantages of this process. On the one hand, it does not require cleaning agents or the disposal of residual waste, and therefore has very low operating costs. On the other hand, it is very precise and protects the surface. Above all, the use of laser rays achieves excellent cleaning results. All kinds of oxides, dust particles and especially impurities formed by polymer lubricants, which are very difficult to remove, can be evaporated by the laser in a matter of seconds. The laser-cleaned surfaces are ideally suited for further processing, such as laser welding.

Sample Photos:

Product Parameter:

Model: | HLC-P200W | HLC-P300W | HLC-P300W |

Operational Voltage: | 220V±10%、50/60Hz customisable:110V、50Hz alternating current | ||

Temperature: | 5℃ ~40℃ | ||

Humidity: | 30-85% Non-Condensing | ||

Power dissipation: | ≤1500W | ≤2000W | ≤4000W |

Power Output: | 200W | 300W | 300W |

Laser Type: | Fibre | ||

Maximum Pulse Energy: | 1.5mJ/2mJ/5mJ | 1.5mJ/5mJ | 12.5mJ |

Pulse Frequency Range: | 1-4000kHz(Gradient adjustable) | 1-4000kHz(Gradient adjustable) | 1-4000kHz(Gradient adjustable) |

Pulse Width: | 2-500ns tunable | 2-500ns tunable | 2-500ns tunable |

Output Power Instability: | <5% | ||

Wavelength: | 1064 nm | ||

Head Cable Length: | 5 m | 5 m | 5 m |

Cooling: | Air cooling | Water cooling | |

Focus Distance: | 210mm | 210mm | 210mm |

Scanning mode: | Dual-axis; supports 9 scanning modes | ||

Head Weight: | ≤0.9Kg | ≤1.25Kg | |

Size W x H x D: | About 629mm*341mm*734mm | About 982mm*458mm*791mm | |

Box Dimensions | About 800mm*470mm*880mm | About 1130mm*580mm*1050mm | |

Entire Unit Weight: | About 52Kg | About 135Kg | |

Packed weight: | About 67Kg | About 165Kg | |

Operation Mode: | Handheld/Automation | ||

Safety Class: | Level IV | ||

Application:

Use Cases:

FAQ:

1. What materials can be cleaned by laser cleaning?

Aluminium - Carbon fibre reinforced plastics - Steel - Silicon - Copper - Plastic - Copper - Thermoplastics -Titanium - composite materials - nickel - chromium - ceramics - cast iron - marble - carbide, etc.

2. Is there any damage to the cleaning material?

Pulse type has finer cleaning effect while continuous type has faster cleaning speed, relative to material damage, pulse type is less than continuous type. By optimising the algorithm and increasing the speed, we can achieve basically no damage to the substrate.

3. How many cleaning modes are currently supported?

Currently, we support 9 modes: Linear, Rectangle I, Rectangle II, Circle, Sine, Spiral, Free, Circle and Rotary.

3. Language interface

Currently support Chinese, Chinese traditional, English, Russian, Japanese, Spanish, German, Korean, French and other 16 languages

4.Product Application

This machine is suitable for removing all kinds of stains, including rust layer, paint, oil, coating, oxidation layer, adherence on stone statues (detailed to dust level), and rubber moulding residue. In addition, it is also suitable for pre-treatment of welded/painted surfaces.