Durable Fiber Laser Cleaning Machine

1. Superior Cleaning Performance

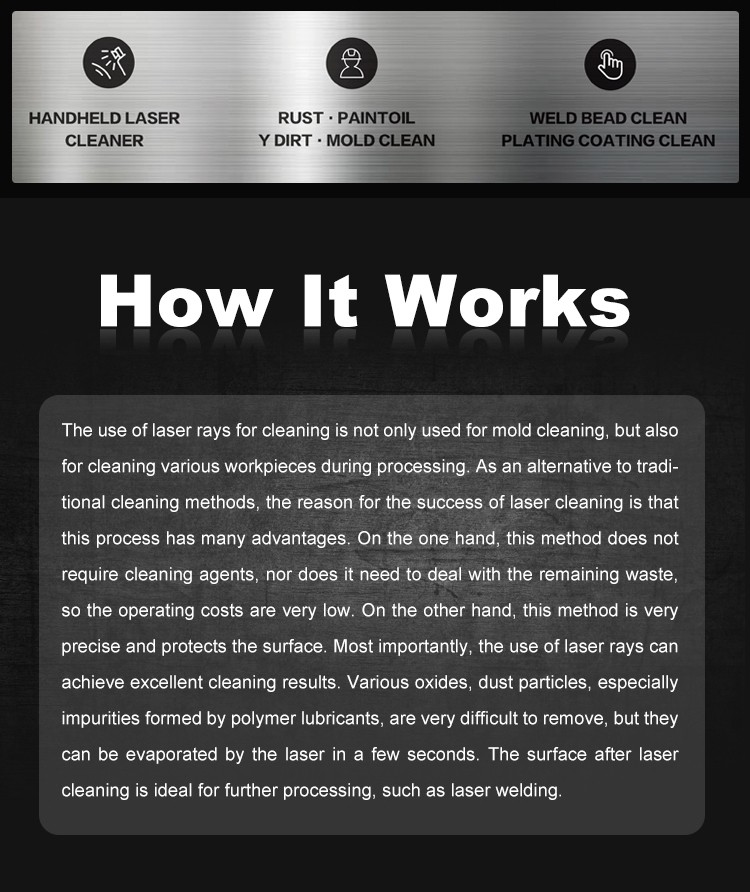

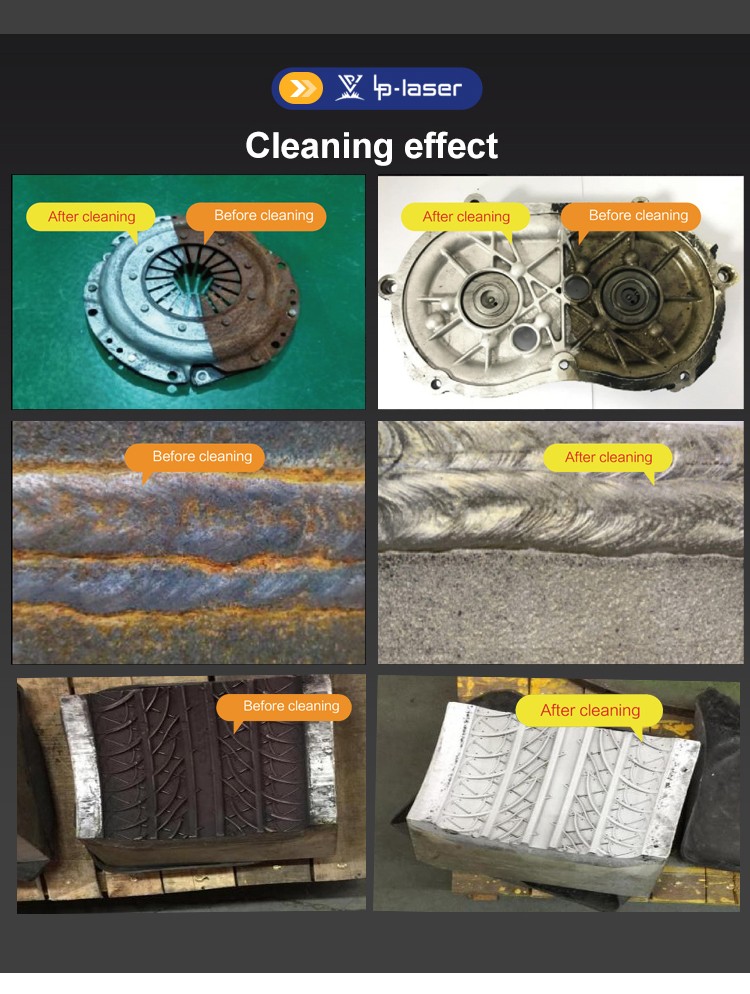

Non-contact, non-abrasive process preserves material integrity

Removes rust, paint, oxides, oil, coatings with micron-level precision

Adjustable power (200W-1000W+) for different material thicknesses

2. Unmatched Efficiency & Cost Savings

3-5X faster than sandblasting/chemical methods

Zero consumables - no media, chemicals or abrasive materials needed

Low maintenance design with 100,000+ hours laser source lifespan

3. Eco-Friendly & Safe Solution

No toxic chemicals or hazardous waste - fully RoHS/CE compliant

No secondary pollution - protects operator health and environment

No substrate damage - perfect for delicate surfaces and artifacts

4. Smart & User-Friendly Operation

Lightweight & portable designs available (stationary/mobile units)

Intuitive interface with preset programs for common materials

Automated scanning options for large-area cleaning

5. Industrial-Grade Durability

IP54 protection for harsh workshop environments

Air/water-cooled options for continuous operation

Modular design for easy maintenance and part replacement

Product introduction

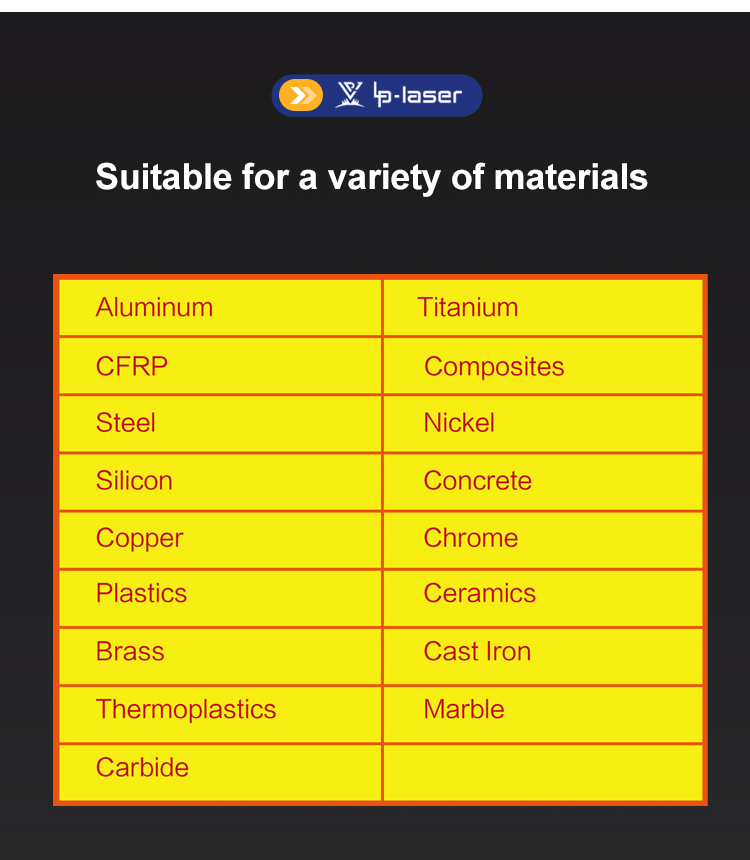

The Fiber Laser Cleaning Machine is a cutting-edge industrial tool used for precision cleaning of various surfaces. It employs advanced fiber laser technology to remove rust, paint, grease, oxide layers, and other contaminants without causing damage to the substrate material. This machine is highly versatile and can be applied in industries such as automotive, aerospace, marine, metalworking, and more. With features such as adjustable laser power, high cleaning efficiency, minimal maintenance requirements, and environmentally friendly operation (no chemicals or abrasive materials needed), the Fiber Laser Cleaning Machine is an ideal solution for achieving pristine and ready-to-coat surfaces in a cost-effective manner.

Model: | HLC-P200W | HLC-P300W | HLC-P300W(water-cooling) |

Operational Voltage: | 220V±10%、50/60Hz Customizable: 110V, 50Hz AC | ||

Temperature: | 5℃~40℃ | ||

Humidity: | 30-85% Non-Condensing | ||

Power dissipation: | ≤1500W | ≤2000W | ≤4000W |

Power Output: | 200W | 300W | 300W |

Laser Type: | Optical fiber | ||

Maximum Pulse Energy: | 1.5mJ/2mJ/5mJ | 1.5mJ/5mJ | 12.5mJ |

Pulse Frequency Range: | 1-4000kHz(Gradient adjustable) | 1-4000kHz(Gradient adjustable) | 1-4000kHz(Gradient adjustable) |

Pulse Width: | 2-500ns tunable | 2-500ns tunable | 2-500ns tunable |

Output Power Instability: | <5% | ||

Wavelength: | 1064 nm | ||

Head Cable Length: | 5 m | 5 m | 5 m |

Cooling: | Air cooling | water-cooling | |

Focus Distance: | 210mm | 210mm | 210mm |

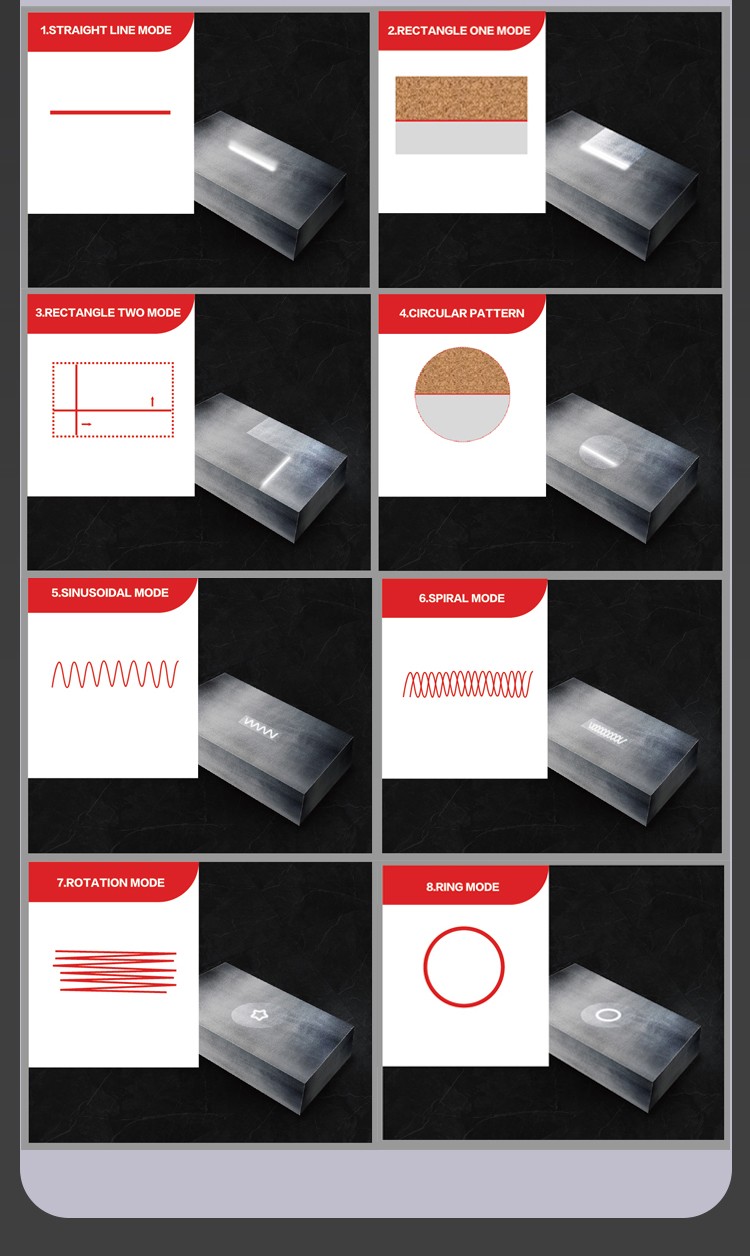

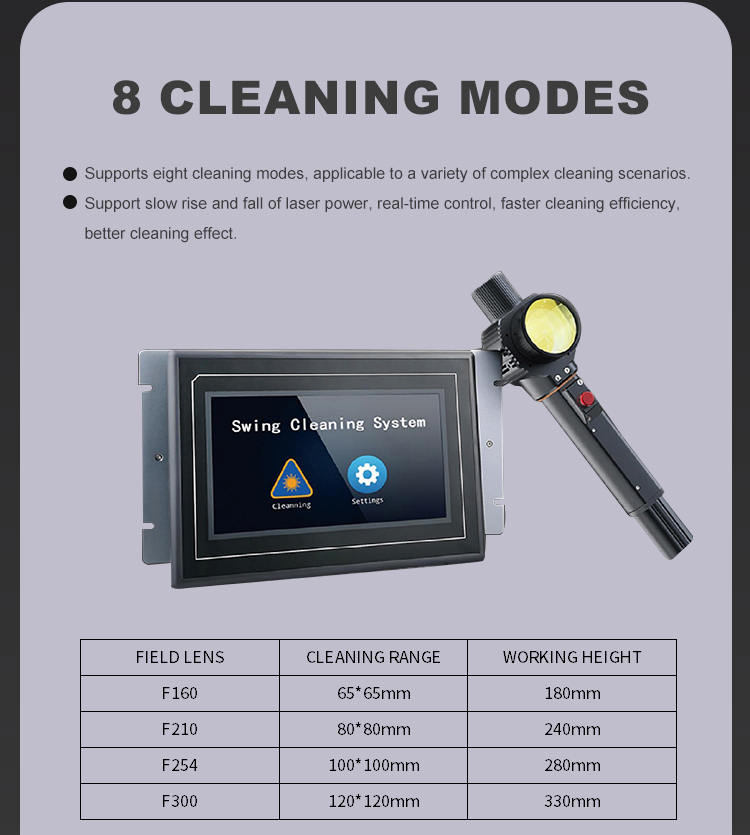

Scanning mode: | Dual axis; Nine scanning modes are supported | ||

Head Weight: | ≤0.9Kg | ≤1.25Kg | |

Size W x H x D: | About629mm*341mm*734mm | About982mm*458mm*791mm | |

Box Dimensions | About800mm*470mm*880mm | About1130mm*580mm*1050mm | |

Entire Unit Weight: | About 52Kg | About 52Kg | About 135Kg |

Packed weight: | About 67Kg | About 67Kg | About 165Kg |

Operation Mode: | Handheld/Automation | Handheld/Automation | |

Safety Class: | Level IV | Level IV | |

Q: Can lasers clean welds or post-weld residues?

A: Yes—ideal for removing slag, oxides, and discoloration from TIG/MIG welds.

Q: Does it affect weld strength?

A: No, it only cleans the surface without altering metallurgy.

Q: Is it better than grinding?

A: Yes—no material loss or heat-affected zones (HAZ).