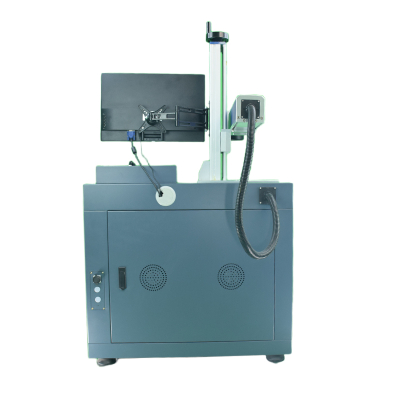

Laser marking machine device

The laser marking machine device is usually composed of several parts: the laser source, the lighting system, the cooling system, and the control system. Depending on the type of laser used, it can be classified as C02 laser, Nd:YAG laser, etc.

For the surfaces of general metals and dark plastics, use phosgene and excimer laser Nd:YAG for marking. For the surfaces of ceramics and transparent materials, use CO2 laser. According to the working mode of the laser marking device, it can be divided into mask method, which has three progressive methods and true line scanning method.

1.Mask display method: The mask display method is also known as the projection display method. On a template, special numbers, characters, patterns and other fragments are printed to form the mask. The mask image is projected onto the workpiece through the lens. The main advantage of the mask marking is that laser pulses can complete various matching markings at once.

Therefore, the marking speed is fast and it is suitable for a large quantity of single-variety products. However, due to the complexity of mask production, it is not suitable for complex patterns. It also requires frequent replacement of the marking. (William Shakespeare). Template. Mask. Mask. Mask. Mask. Mask. Mask. Mask. The mask marking method generally uses mask marking method C02 laser and excimer laser.

2. Grating marking method: One or more small lasers are simultaneously activated to emit pulses. After passing through a reflector and a focusing lens, small depressions of allowed size are removed from the surface of the material that displays one or more laser pulses. Each pattern and text is composed of these small depressions. The marking speed based on gratings is relatively slow and is suitable for marking of planar images (such as photographs), but if the text is marked again and enlarged, the frame will not be smooth.

3. The laser marking machine uses the true reading scanning display method. The 3360 true reading display method involves directing the laser beam onto two reflecting mirrors (true reading), and the scanning mirror is controlled by the computer, which can scan onto the X-Y axes of the lead.

Click on numbers, text, graphics, etc. on the designated plane. The marked area can be very large or very small. Multiple small components can be marked simultaneously, or multiple characters and patterns can be displayed on one component. In simple terms, the scanning method involves using a laser "pen" to imprint on the workpiece that needs processing.