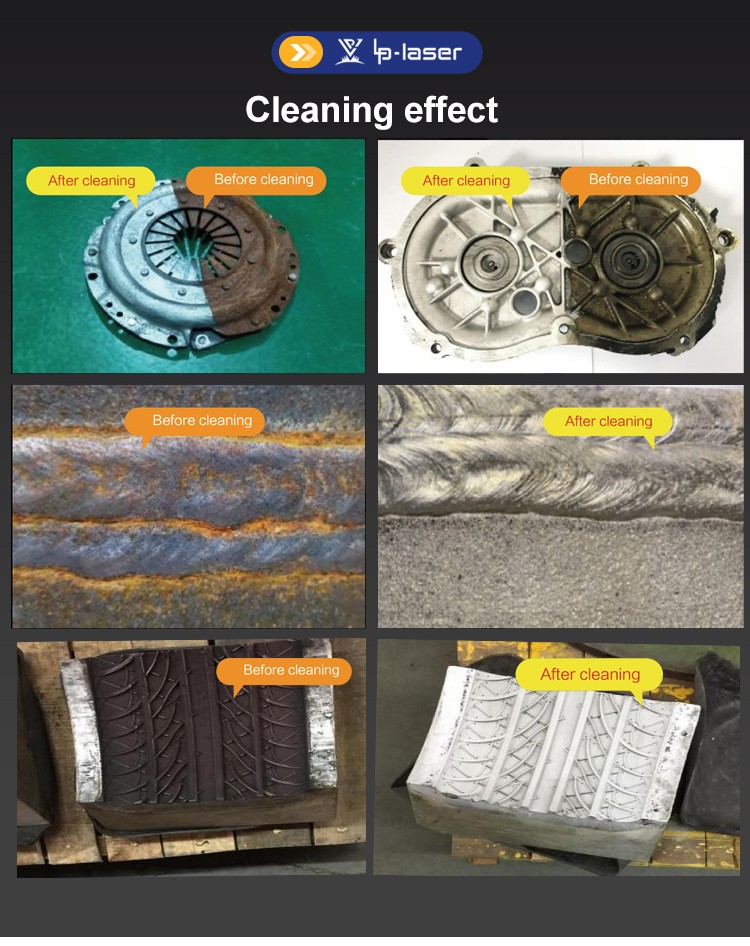

High quality Pulsed Laser Cleaning Machine

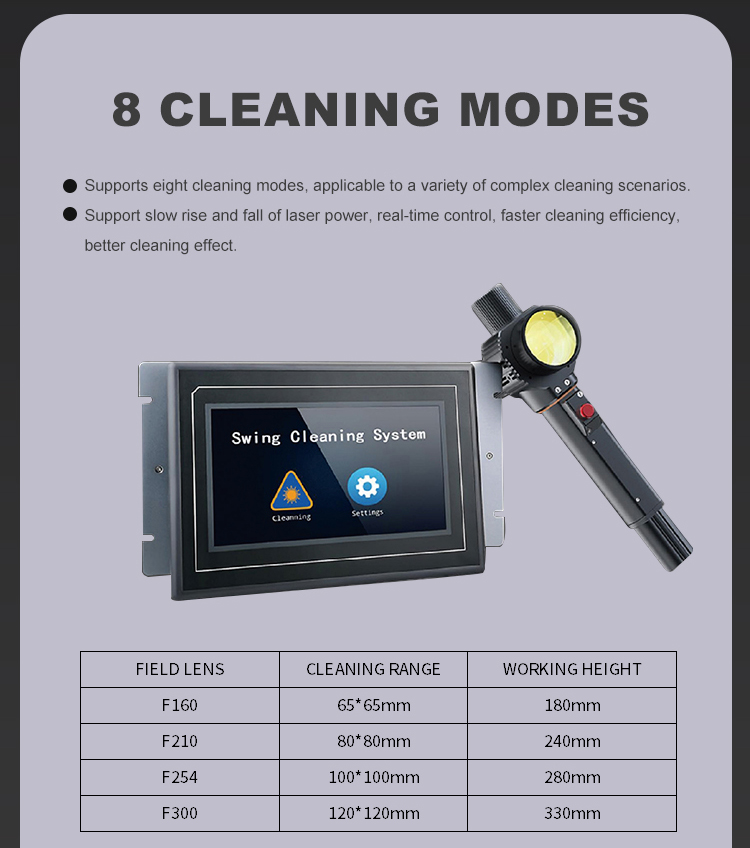

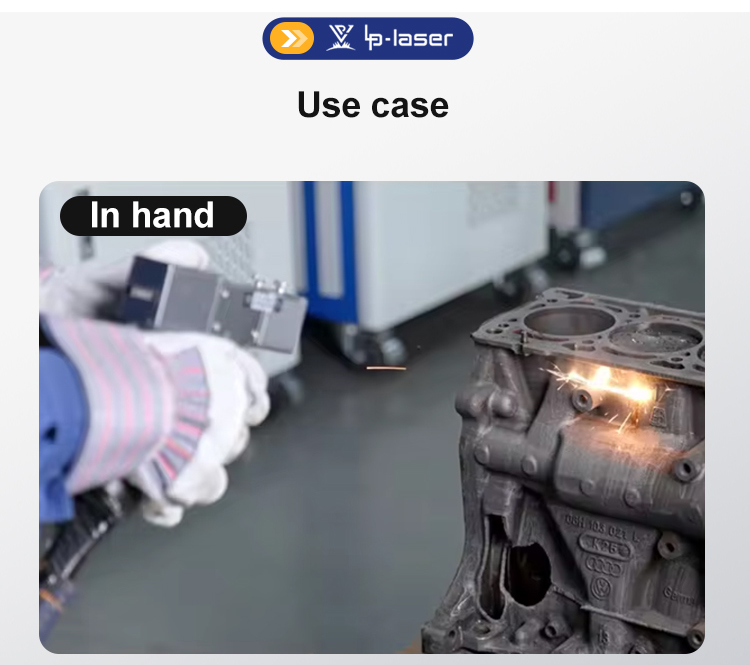

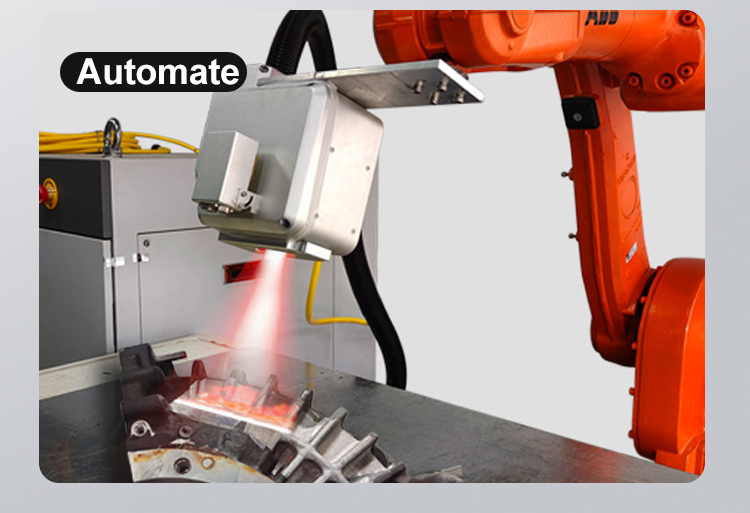

High efficiency: The pulse laser cleaning function can complete the cleaning task in a very short time, significantly improving the work efficiency.

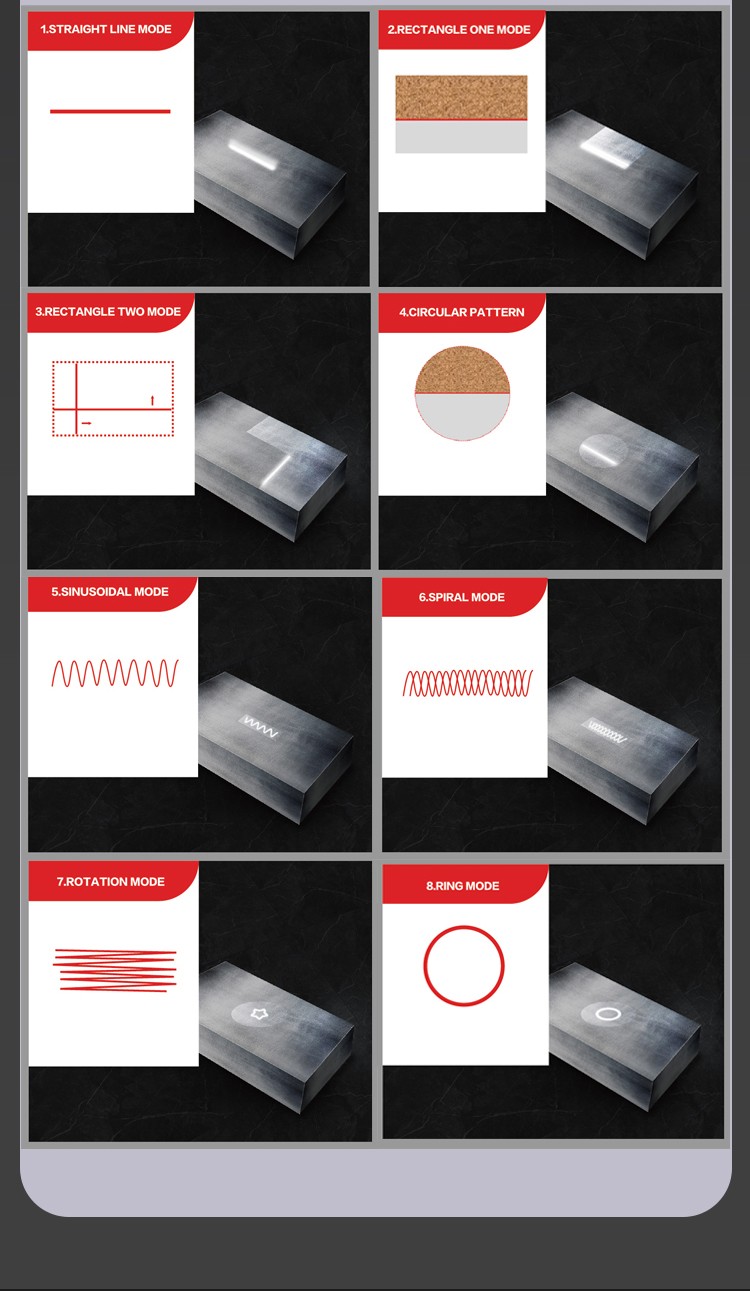

Accuracy: The laser beam can be precisely controlled down to the micron level for precise cleaning of specific areas.

Non-destructive: The non-contact cleaning method will not cause mechanical or thermal damage to the substrate.

Environmental protection: no need to use chemical cleaning agents, reducing pollution to the environment.

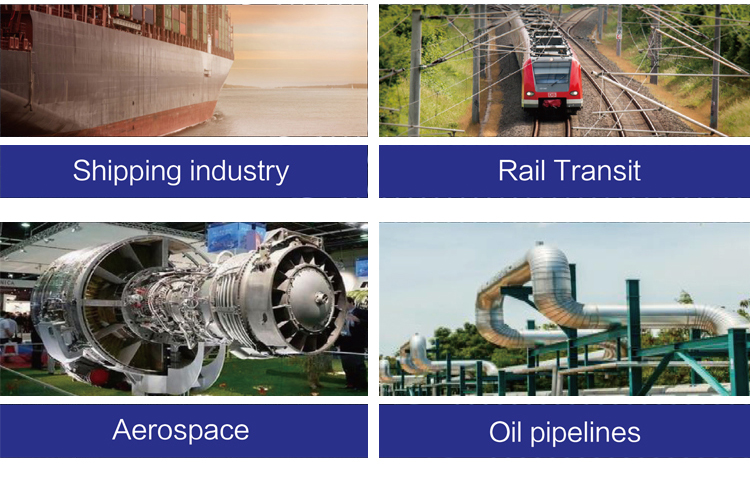

Wide applicability: suitable for surface cleaning of various materials, including metal, non-metal, glass, ceramics, etc.

Pulsed laser cleaning machine product introduction

Pulsed laser cleaning machine is a high-tech equipment that uses high energy pulsed laser beam for surface cleaning. Through the interaction between the laser beam and the surface of the material, the instantaneous high temperature and high pressure effect makes the stain, coating or oxide quickly peel off, achieving an

efficient, accurate and non-destructive cleaning effect. Pulsed laser cleaning machine is widely used in all kinds of metal, non-metal material surface cleaning, as well as precision instruments, art, ancient buildings and other fine surface cleaning treatment.

| LASER POWER | 300W |

Working voltage | 110/220V 50/60 HZ |

| Laser Working Mode | Pulse |

| Average laser power | ≥300W |

Power instability | <5% |

| Maximum Pulse Energy | 15mJ |

| Pulse width | 2-500ns |

| Cooling method | water cooling |

| Power regulation range(%) | 0-100( Gradient Adjustable) |

| Fiber length | 5m |

| Cleaning head weight (including isolator) | <1.5Kg |

| Working environment humidity | ≤80% |

| Working environment temperature | 10℃~40℃ |

Product principle:

Pulsed laser cleaning machine through the high energy pulsed laser beam irradiation on the surface of the object to be cleaned, the laser beam and the material surface interaction, the instant high temperature and high pressure effect makes the stain, coating or oxide quickly gasification, stripping, so as to achieve the purpose of cleaning. At the same time, due to the precise control of the laser beam, precise cleaning of a specific area can be achieved to avoid damage to the surrounding area.

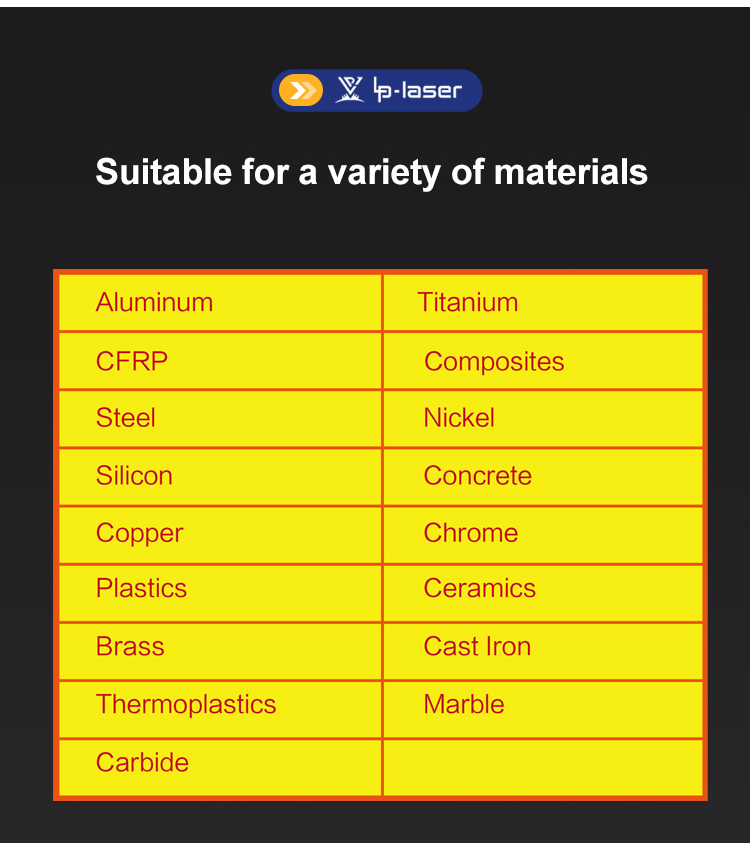

Q1: What is the material compatibility of your laser cleaning system?

A1: The system is compatible with a wide range of materials including:

Metals - Aluminum, Steel, Copper, Titanium, Nickel, Chromium, Cast Iron

Composites - Carbon fiber reinforced plastics, Engineering plastics, Thermoplastics

Others - Ceramics, Marble, Carbide, Silicon

Q2: How does pulse vs continuous laser affect substrate integrity?

A2: Pulse lasers provide superior precision with minimal thermal impact, while continuous lasers offer higher throughput. Our advanced algorithm optimization enables damage-free cleaning on most substrates when operating at optimal parameters.