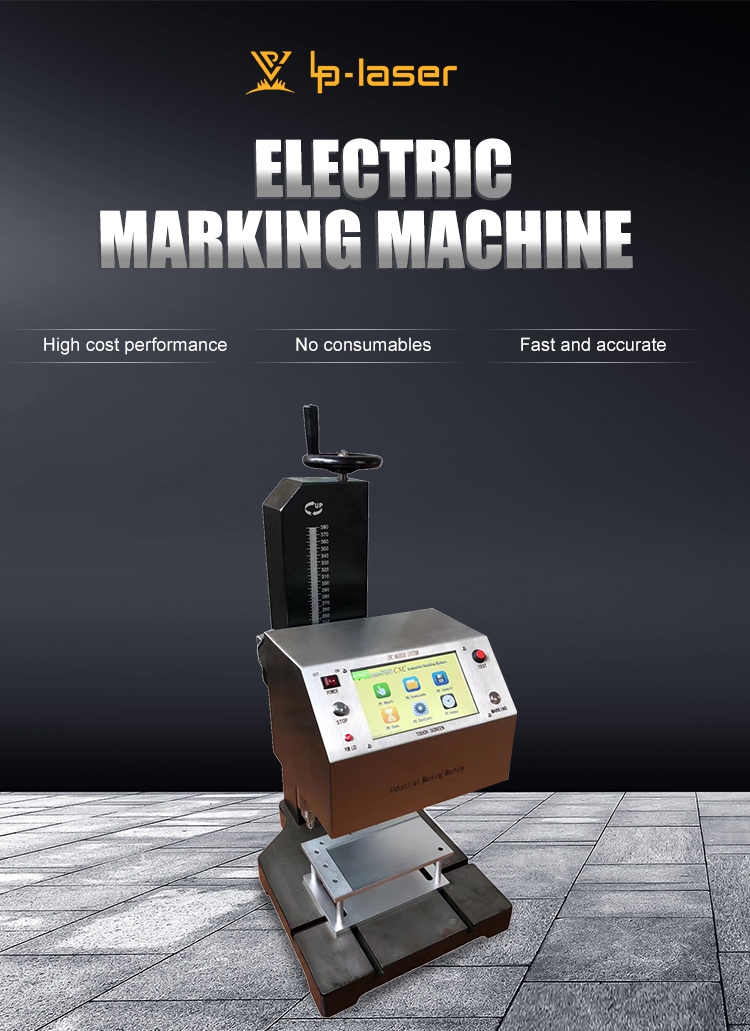

Electric Desktop Laser Marking Machine

High Marking Precision

Fine Focusing: The laser beam of the electric desktop laser marking machine can be focused to a very small spot, achieving high-precision marking. It can clearly mark complex patterns and tiny characters with a minimum line width reaching 0.04mm, meeting the requirements of fine processing.

Accurate Positioning: Equipped with an advanced positioning system, it ensures accurate marking positions with a re-positioning accuracy of up to 0.001mm. This allows for consistent and precise marking on different workpieces.

Excellent Marking Quality

Permanent and Durable: The marks made by the laser are permanent and resistant to fading, wear, and corrosion. They can withstand various environmental conditions, ensuring long-term clarity and integrity of the markings.

High Contrast: It can produce marks with high contrast, making the marked information clear and easy to read. Whether it's marking on metal or plastic materials, the resulting marks have a distinct appearance.

Wide Material Applicability

Versatile Material Compatibility: It can mark on a wide range of materials, including metals such as steel, aluminum, copper, and titanium, as well as non-metals like plastics, ceramics, glass, and painted substrates. This makes it suitable for various industries and applications.

High Efficiency and Productivity

Fast Marking Speed: With an imported scanning system, the marking speed can reach up to 7m/s, enabling quick completion of marking tasks. It can significantly improve production efficiency, especially in mass production scenarios.

Continuous Operation: The machine has high stability and can operate continuously for a long time. It has a laser module life of up to 120,000 hours, reducing downtime and maintenance costs.

Easy to Operate and Use

User-Friendly Software: It comes with specific marking software based on Windows, which is easy to use. Users can easily adjust parameters such as laser power and pulse frequency in real-time. They can also input and edit marking content through the software, supporting various file formats like JPG and JPEG.

Compact and Portable: The desktop design makes it compact in size and easy to install and use on a workbench. It doesn't take up much space and can be moved easily within the workshop, providing convenience for different production needs.

Energy Saving and Environmental Friendly

High Electro-Optical Conversion Efficiency: The electro-optical conversion efficiency can reach up to 30%, which means it consumes less energy while maintaining high performance. This helps save energy and reduce operating costs.

No Pollution: The laser marking process is a non-contact and pollution-free process. It doesn't produce any harmful gases, liquids, or solid waste, meeting environmental protection requirements.

Product Introduction

The Electric Desktop Laser Marking Machine is a high-precision marking device designed for various marking applications. It utilizes advanced laser technology to project a high-energy laser beam onto the surface of workpieces.

It consists of a laser generation system, a control system, and a marking head. The laser generation system produces a stable and high-quality laser beam. The control system, usually operated by a computer, enables precise control of the marking process, allowing users to input and edit marking content such as patterns, characters, and barcodes. The marking head, which is equipped with optical components, focuses the laser beam onto the workpiece surface to complete the marking task.

| Model | EM-100x170 |

| Type | Electric、 Hand Held、Dot Peen、 marking |

| Controller | Built-In Software and Touch Screen |

| Marking Area | 100mm x170mm |

| Marking Speed | 1-4 characters/s (5mm height) |

| Marking Depth | 0.1mm-1mm(according to material) |

| Power supply | AC 100V -240V 50HZ/60HZ |

| Marking Content | English characters, number, all kinds of graphicoutline, logo, dot matrix 2D codes, Barcode, SerialNumber, circle Letter and etc. |

| Power dissipation | <400W |

Q1: How does the speed of the laser marking machine affect cost - effectiveness?

A1: A higher marking speed means you can mark more nameplates in less time, increasing productivity. This directly improves cost - effectiveness as you can meet more orders with the same amount of labor and energy. However, you need to ensure that the quality of the marking does not deteriorate at high speeds, so proper parameter adjustment is necessary.

Q2: What kind of maintenance is required for the laser marking machine to maintain cost - effectiveness?

A2: Regularly clean the exterior of the machine to prevent dust and debris from affecting its performance. Check and clean the optical lenses and mirrors to ensure the laser beam is properly focused. Monitor the laser source's performance and replace it when necessary according to the manufacturer's recommendations. Also, keep the cooling system in good condition to prevent overheating.

Q3: Can I use the laser marking machine for marking on both flat and curved nameplates?

A3: Yes, many Electric Nameplate Laser Marking Machines can be used for both flat and curved nameplates. For curved surfaces, you may need to use additional fixtures to hold the nameplate in place and ensure the laser beam is perpendicular to the marking surface. Some machines also have features like dynamic focusing to adjust for the curvature and maintain consistent marking quality.