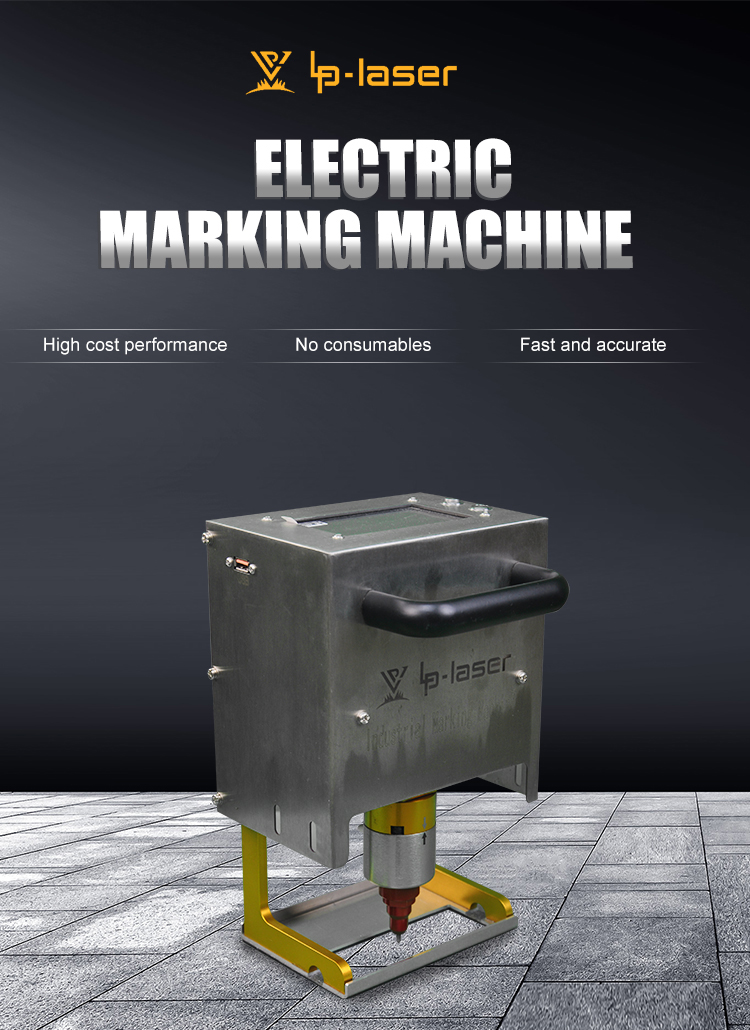

Electric Handheld Laser Marking Machine

1.Portability and Flexibility

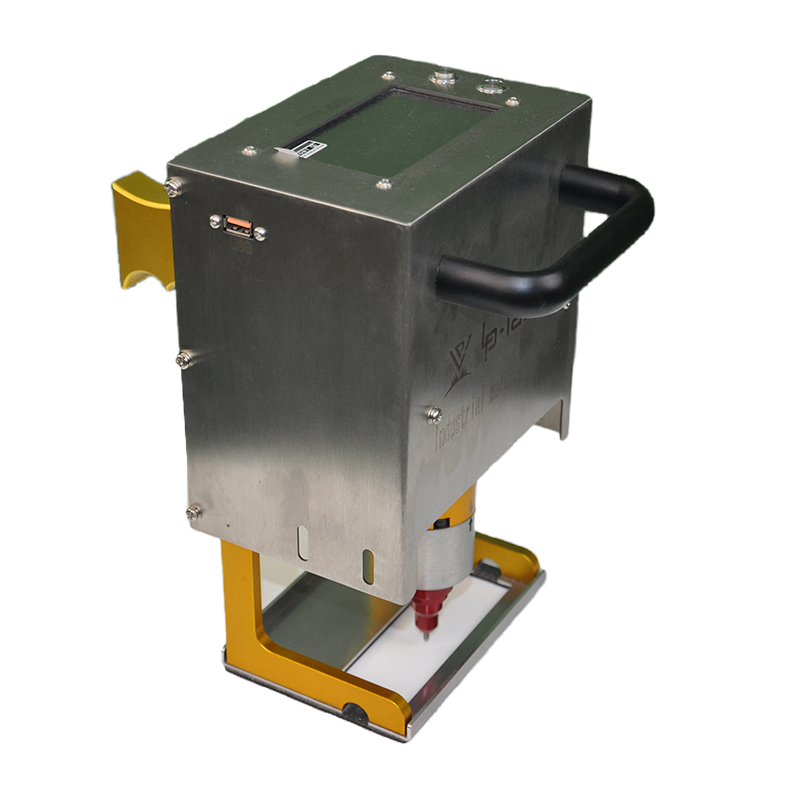

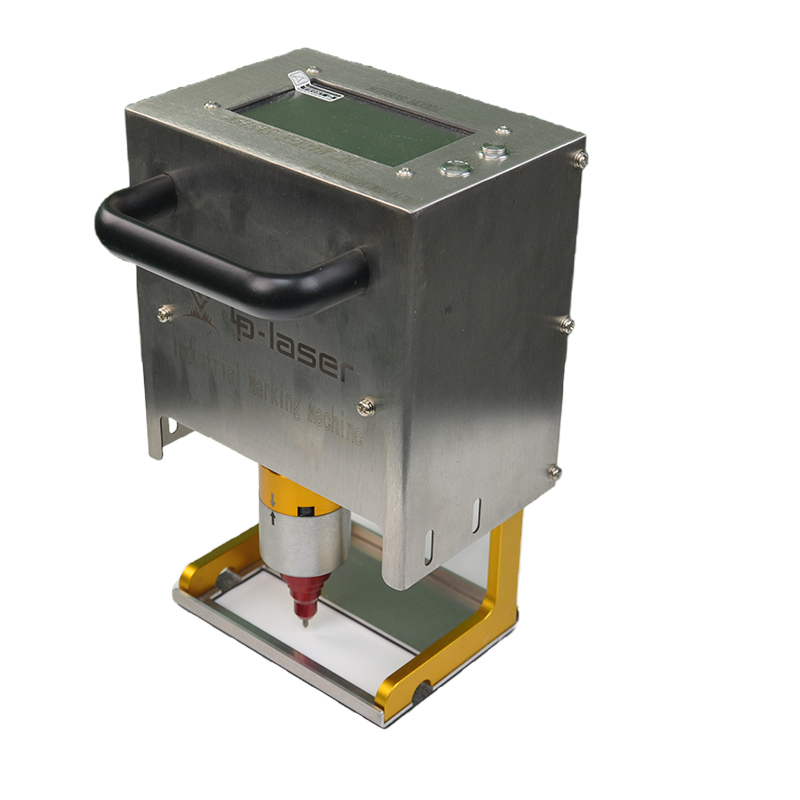

Lightweight and Compact: The marking head of the electric handheld laser marking machine is small and lightweight, usually weighing only about 1.25 kg, which is easy to hold and operate. It can be carried and used in different locations, and is not subject to space restrictions.

Easy to Use: It can be used immediately after simple training. It is very convenient to use in the field or in a small workshop, and can meet the needs of on-site marking at any time.

2.High Marking Quality

High Precision: It adopts advanced laser technology to achieve micron-level marking accuracy. It can clearly and finely mark various complex patterns and small characters on the surface of the material, and the minimum line width can reach 0.04mm.

Permanent Marking: The marks made by the laser are permanent and will not fade or fall off due to environmental factors such as contact, acid and alkali gases, high and low temperatures.

3.Wide Material Applicability

Diverse Material Compatibility: It can mark on a variety of metal and non-metal materials, including common metals such as steel, titanium, aluminum, copper, as well as ceramics, plastics, glass, wood, paper and cardboard.

4.High Efficiency and Energy Saving

Fast Marking Speed: The laser beam can move at a high speed of 5-7 meters per second under the control of the computer, and a marking process can be completed in just a few seconds, which greatly improves the production efficiency.

Low Energy Consumption: Although the power of the equipment is not high, it can complete the marking work efficiently, and the energy consumption in the operation process is small, which helps to save energy and reduce costs.

5.Non-contact Processing

No Damage to Workpiece: The non-contact processing method of the laser avoids the generation of mechanical stress and damage on the surface of the workpiece, and will not cause corrosion or wear to the processed object, which is very suitable for the marking of precision parts and surface-sensitive materials.

No Pollution: The marking process does not produce any toxic or harmful gases, liquids or solid waste, which is in line with the requirements of environmental protection.

Product Introduction

The Electric Handheld Laser Marking Machine is a portable and high-efficiency marking device designed to meet various marking needs in different industries. It utilizes advanced laser technology to project a focused high-energy laser beam onto the surface of the workpiece through a handheld marking head. Controlled by a precise control system, it can quickly and accurately mark various patterns, characters, barcodes and other information on the surface of different materials.

| Model | EM-40x90 |

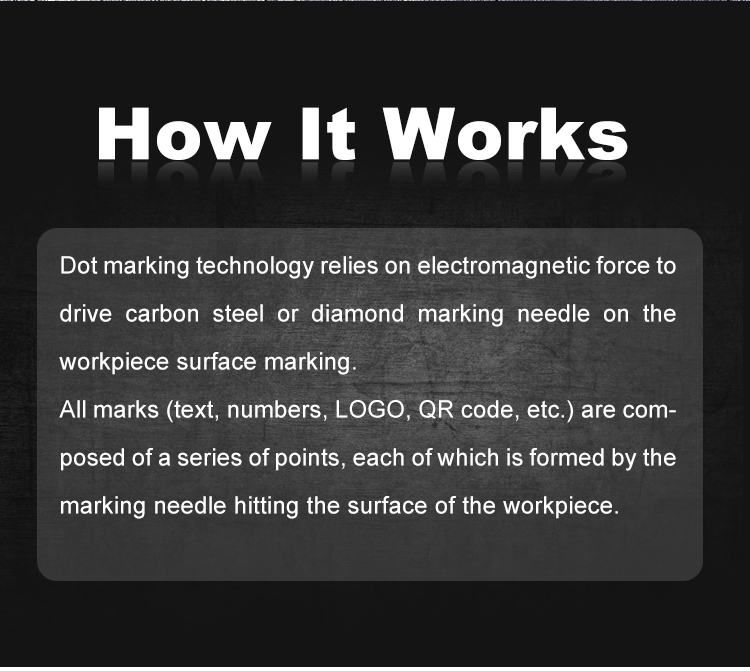

| Type | Electric、 Hand Held、Dot Peen、 marking |

| Controller | Built-In Software and Touch Screen |

| Marking Area | 40mm x 90mm |

| Marking Speed | 1-4 characters/s (5mm height) |

| Marking Depth | 0.1mm-1mm(according to material) |

| Power supply | AC 100V -240V 50HZ/60HZ |

| Marking Content | English characters, number, all kinds of graphicoutline, logo, dot matrix 2D codes, Barcode, SeriaNumber, circle Letter and etc. |

| Power dissipation | <400W |

Q1: Is the cost of software updates for the laser marking machine significant in terms of cost - effectiveness?

A1: In most cases, software updates are either free or come at a very low cost. These updates often bring new features, improved performance, and better compatibility with different file formats. The enhanced functionality can increase productivity, such as faster marking speeds or more accurate alignment, which outweighs the minimal cost of updates, thus improving cost - effectiveness.

Q2: How does the energy consumption of the laser marking machine impact cost - effectiveness?

A2: The energy consumption of the machine is relatively stable. Although it does consume electricity during operation, compared to the cost savings from increased productivity and reduced use of other marking - related consumables, the energy cost is usually a minor factor. However, to further improve cost - effectiveness, you can ensure the machine is only running when needed and consider using energy - efficient settings if available.

Q3: How can I ensure the cost - effectiveness of the machine in the long run?

A3: Regularly maintain the machine as per the manufacturer's guidelines. This includes cleaning the optical components, checking the laser source, and ensuring proper cooling. Also, train your operators well to maximize productivity and minimize errors. Additionally, keep an eye on the market for any cost - saving upgrades or new features that can enhance the machine's performance.