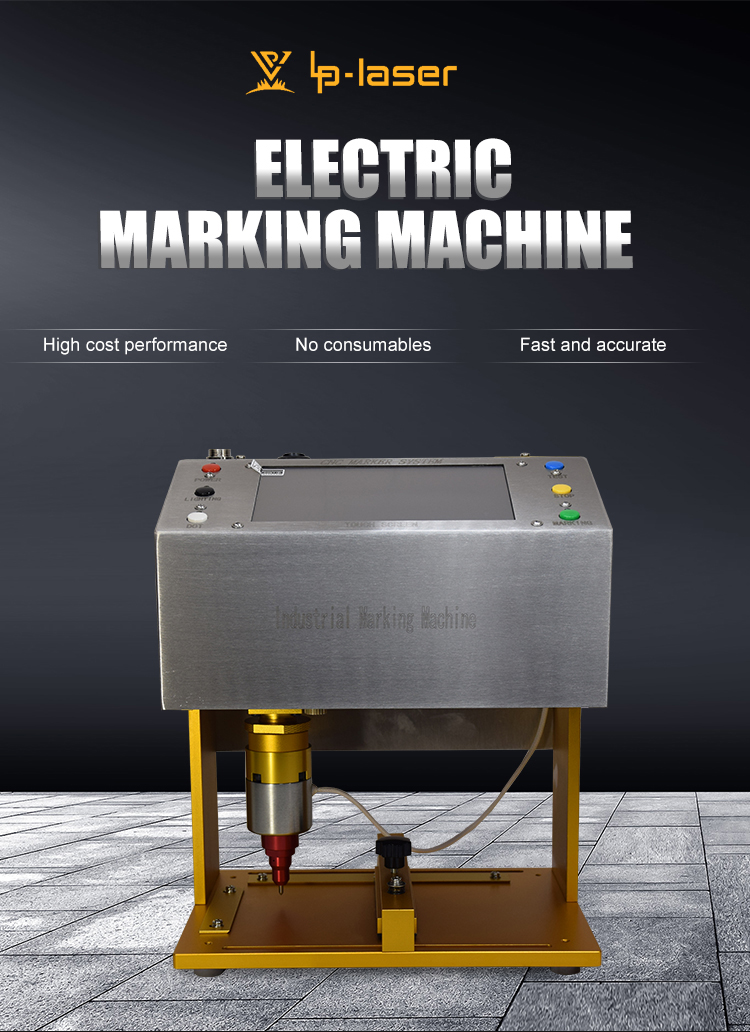

Electric Mameplate Laser Marking Machine

High Precision:The laser beam can be accurately focused to a very small spot, enabling extremely fine and detailed markings. It can achieve high-precision engraving of text and graphics, ensuring clear and sharp edges, which is crucial for nameplate identification and aesthetics.

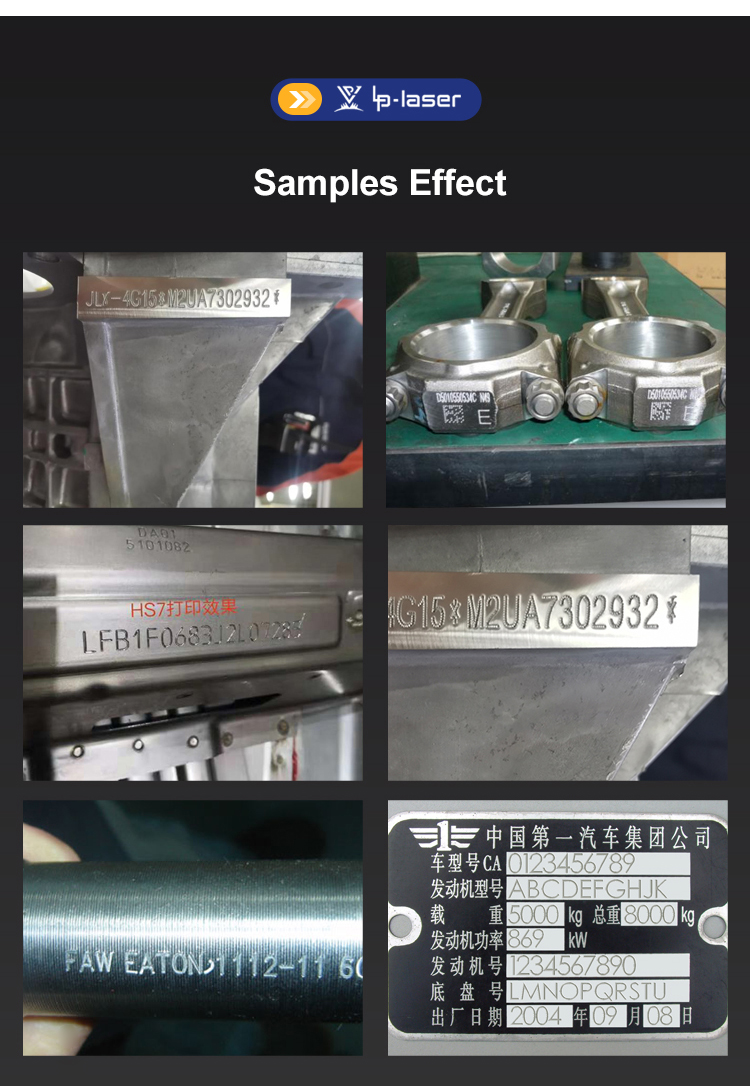

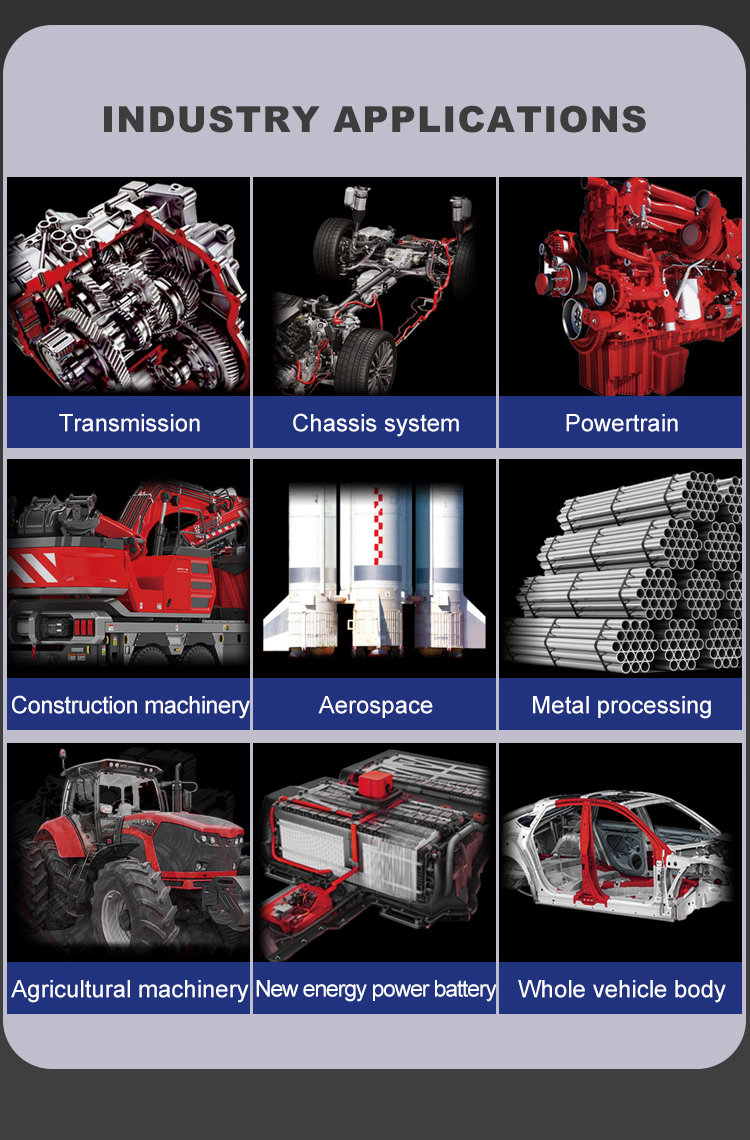

Wide Material Compatibility:Capable of marking on a variety of materials, it provides great flexibility for different nameplate production requirements. Whether it's stainless steel, aluminum alloy, plastic or other materials, the machine can produce excellent marking effects.

Fast Marking Speed:With advanced laser control technology, it can complete marking tasks at a high speed. This not only improves production efficiency but also helps to reduce overall production costs, making it an ideal choice for mass production.

Permanent Markings:The markings made by the laser are resistant to wear, corrosion, and fading, ensuring that the information on the nameplates remains clear and intact for a long time. This enhances the durability and reliability of the nameplates.

Low Maintenance Cost:The machine is designed with a simple structure and high-quality components, requiring minimal maintenance. It has a long service life, reducing the need for frequent replacements and repairs, thus saving maintenance costs and improving overall cost-effectiveness.

Product Introduction

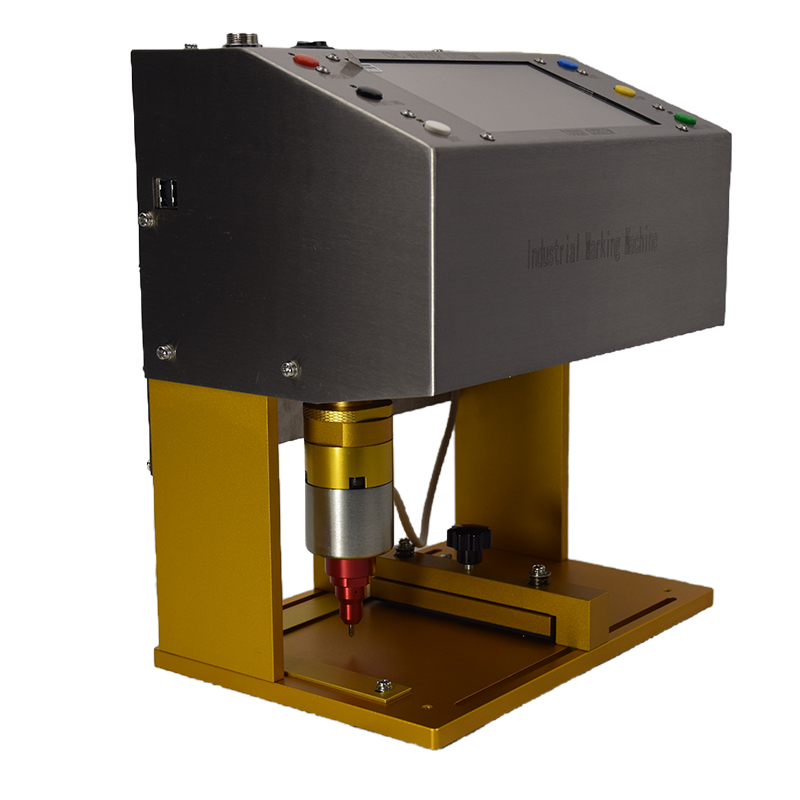

The Electric Nameplate Laser Marking Machine is a highly advanced and innovative device designed for precise and efficient marking on nameplates.

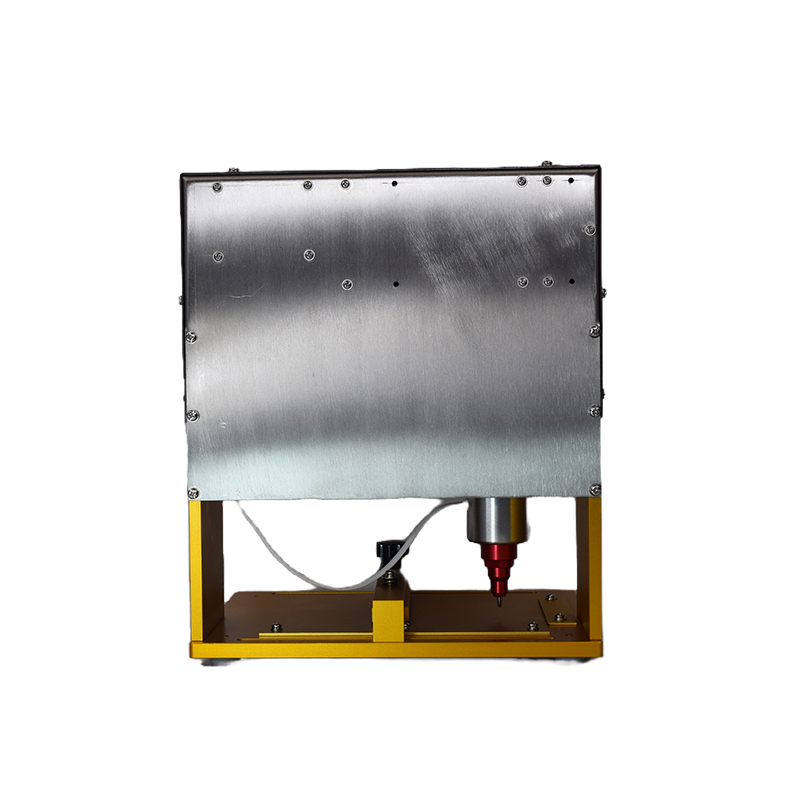

It utilizes state-of-the-art laser technology to create permanent and clear markings on various materials used for nameplates, including metal, plastic, and composite materials. The machine is equipped with a high-power laser source that ensures strong beam intensity and stability, enabling it to handle different marking tasks with ease.

With its user-friendly interface, operators can easily input and edit the marking content, such as text, logos, barcodes, and QR codes. The machine supports a wide range of file formats, allowing for seamless integration with different design software. It also offers high-speed marking capabilities, significantly increasing production efficiency and reducing processing time.

This laser marking machine is designed with a compact and sturdy structure, occupying minimal space in the workshop while ensuring reliable performance and durability. It is suitable for both small-scale and large-scale production lines, meeting the diverse needs of different industries.

| Model | EM-100x170 |

| Type | Electric、 Hand Held 、Dot Peen、 marking |

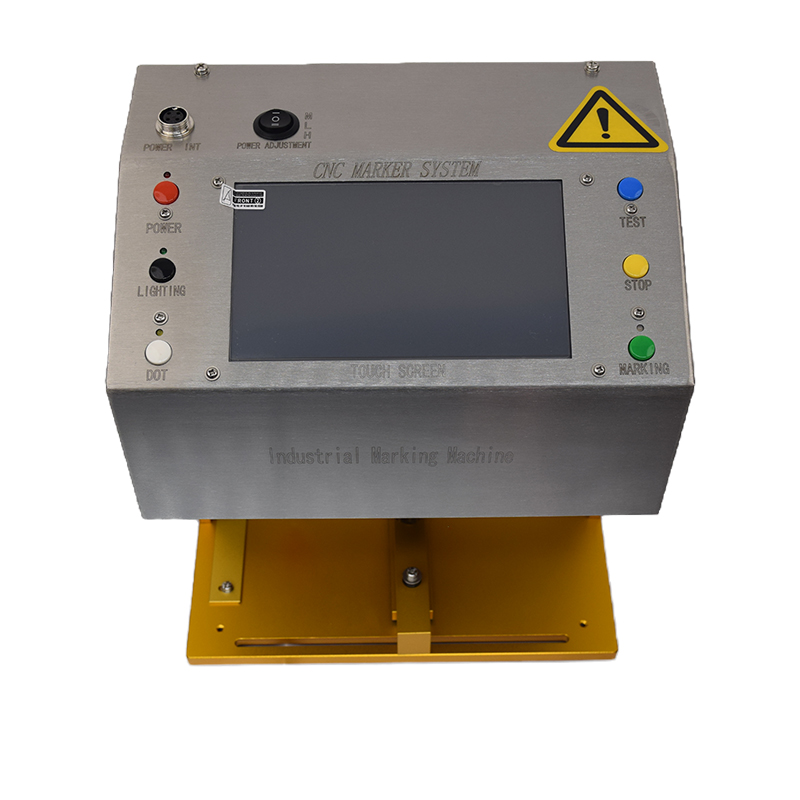

| Controller | Built-In Software and Touch Screen |

| Marking Area | 100mm x 170mm |

| Marking Speed | 1-4 characters/s (5mm height) |

| Marking Depth | 0.1mm-1mm(according to material) |

| Power supply | AC 100V -240V 50HZ/60HZ |

| Marking Content | English characters, number, all kinds of graphicoutline, logo, dot matrix 2D codes, Barcode, SerialNumber, circle Letter and etc. |

| Power dissipation | <400W |

Q1: How does the cost - effectiveness of an Electric Nameplate Laser Marking Machine compare to traditional nameplate marking methods?

A1: The Electric Nameplate Laser Marking Machine is generally more cost - effective. Traditional methods might involve high - cost consumables like inks or stamps. Laser marking, on the other hand, has a one - time investment in the machine. With no need for frequent ink or stamp replacements, it reduces long - term operational costs. Also, its high - speed marking increases productivity, which further improves cost - effectiveness.

Q2: What factors should I consider when calculating the overall cost - effectiveness of this laser marking machine?

A2: Consider the initial purchase price, cost of maintenance (including laser source replacement over time, if applicable), energy consumption, and the cost of any additional software or accessories. Also, factor in the productivity gains, such as how many nameplates it can mark per hour, as increased output can lower the cost per unit marked.

Q3: How do I start using the Electric Nameplate Laser Marking Machine?

A3: First, ensure the machine is properly connected to a stable power supply. Then, turn on the power switch. Next, install and open the dedicated marking software on your computer. Import the marking design (text, logo, etc.) you want to use. Connect the computer to the laser marking machine via the appropriate cable. Finally, set parameters like power, speed, and frequency according to the material of the nameplate, and click the start button to begin marking.

Q4: Can I use the laser marking machine for different types of nameplate materials right out of the box?

A4: Yes, most Electric Nameplate Laser Marking Machines are designed to work with a variety of common nameplate materials like metals, plastics, and some composites. However, you may need to adjust the marking parameters (such as power, frequency, and speed) depending on the specific material to achieve the best marking effect.

Q5: How can I improve the cost - effectiveness of the machine in a small - scale nameplate production business?

A5: In a small - scale business, you can optimize cost - effectiveness by using the machine at its maximum capacity during operation. Plan your production batches to minimize idle time. Also, take advantage of any free or low - cost software updates that may improve the machine's performance. And ensure proper maintenance to extend the lifespan of the machine and avoid costly repairs.