High Quality Engraving Marking Machine

1.High Marking Precision

Fine Details: It can achieve extremely high precision, capable of engraving very small characters and intricate patterns. For instance, it can engrave text with a font size as small as 1mm with clear edges and smooth lines.

Accurate Positioning: With advanced control systems and positioning mechanisms, the engraving machine can ensure that the markings are in the exact position as designed, with a positioning accuracy that can reach micron levels.

2.Excellent Marking Quality

Permanent and Durable: The markings made by the engraving machine are highly resistant to wear, fading, and corrosion. They can remain clear and intact for a long time, even in harsh environmental conditions, ensuring the long-term effectiveness of the markings.

High Contrast and Aesthetics: It can produce markings with high contrast, making the marked information stand out clearly. Whether it's a simple logo or a complex artistic pattern, it can present a high-quality visual effect.

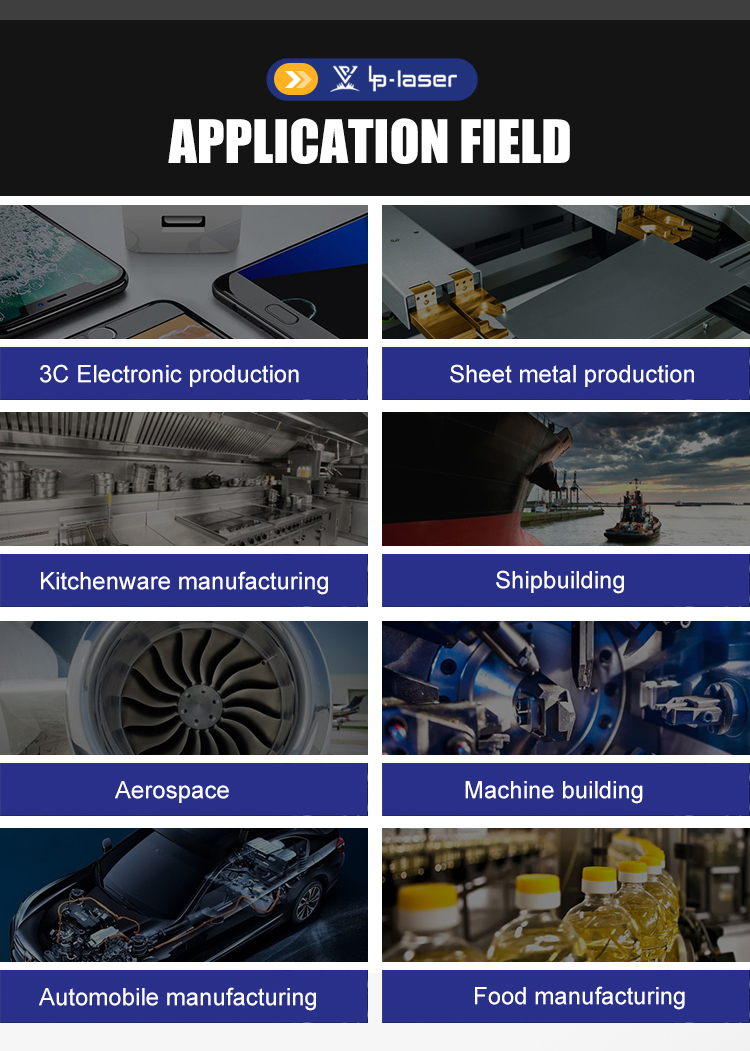

3.Wide Material Applicability

Versatile Material Compatibility: It can work on a wide variety of materials, including metals such as steel, aluminum, copper, and titanium, as well as non-metals like plastics, ceramics, glass, wood, and leather.

Customizable for Different Materials: Different materials can be processed by adjusting the parameters of the engraving machine, such as laser power, engraving speed, and cutting depth, to achieve the best engraving effect.

4.High Efficiency and Productivity

Fast Engraving Speed: The engraving speed is relatively high. For example, a laser engraving machine can complete an engraving task of a simple pattern within a few seconds, which greatly improves the production efficiency, especially in mass production scenarios.

Continuous Operation: With good stability, the engraving machine can work continuously for a long time, reducing downtime and increasing overall productivity.

5.Flexible Operation and Customization

User-Friendly Software: The engraving machine is equipped with dedicated software that allows users to easily design and edit marking content, import graphics and text in various formats, and adjust parameters such as engraving depth and speed according to their needs.

Customizable Marking: It can meet different customization requirements, such as marking serial numbers, barcodes, QR codes, and personalized patterns, to meet the specific needs of different industries and customers.

Product Introduction

The Engraving Marking Machine is a device specifically designed to create permanent and precise markings on the surfaces of various materials. It utilizes different technologies like laser, mechanical, or chemical methods to etch, carve, or cut patterns, characters, logos and other information onto the material surface.

For example, the laser engraving marking machine projects a high-energy laser beam onto the material surface. The heat from the laser beam vaporizes or melts the material in the targeted area, forming clear and accurate marks. Mechanical engraving marking machines, on the other hand, usually use a rotating cutter or stylus to remove material from the surface to create the markings. Chemical engraving marking machines use chemical reactions, such as etching with acid or other corrosive substances, to create patterns on the material surface.

| Laser Type | Fiber Laser |

| Power | 20w/30w/50w |

| Laser Source Brand | MAX/RAYCUS JPT MOPA Optional |

| Marking Area | 70*70mm/110*110mm/150*150mm |

| Minimun Line Width | 0.01mm Depends on the material |

| Minimum Character | 0.2mm Depends on the material |

| Language | Chinese, Korean, Japanese, German, French, Arabic. Spanish,Portuguese, Vietnamese, Farsi, Russian, Thai. etc. |

| Cooling Mode | Air Cooling |

| Net weight | 20kg |

1.Q: What after - sales services are included with the purchase of a fiber marking machine, and do they affect the total cost?

A: Our after - sales services include installation, training, and a certain period of warranty. These services are included in the purchase price and are designed to ensure that you can start using the machine efficiently without incurring additional costs.

2.Q: If I need technical support beyond the warranty period, how much will it cost?

A: We offer flexible technical support packages for after - warranty services. The cost depends on the specific services required, such as on - site repairs or remote technical assistance, but we provide transparent pricing in advance.

3.Q: Does the quality of after - sales service affect the long - term cost - effectiveness of fiber marking machines?

A: Yes, good after - sales service ensures that any issues with the machine are promptly resolved, minimizing downtime and potential production losses. This helps maintain the machine's performance and extends its lifespan, contributing to long - term cost - effectiveness.

4.Q: Are there any hidden costs in the after - sales service of fiber marking machines?

A: There are no hidden costs. All after - sales service charges, if applicable, are clearly communicated before any service is provided. We are committed to providing honest and transparent after - sales support.

5.Q: How can I ensure that I get the best value from the after - sales service of my fiber marking machine?

A: Regularly communicate with our after - sales team about any concerns or potential issues. Follow the recommended maintenance schedule, and take advantage of the training and support resources provided. This way, you can optimize the performance of your machine and get the most out of our after - sales service.