Durable Handheld Laser Cleaning Machine

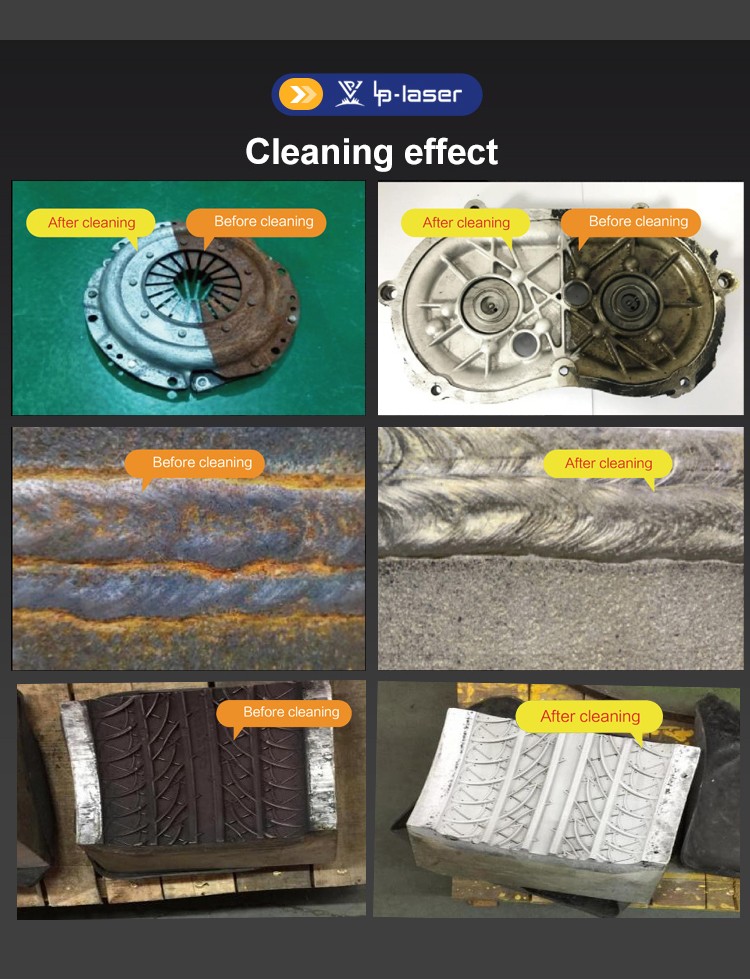

1. Efficient cleaning : laser cleaning can achieve fast operation, greatly shorten the cleaning cycle, improve production efficiency .

2. Environmental protection and pollution-free : no need to use chemical solvents or cleaning solution, to avoid the problem of secondary pollution, clean down the waste volume is small and easy to store and deal with .

3. Non-destructive cleaning : laser cleaning has minimal damage to the substrate, especially suitable for the cleaning and protection of precision parts or historical relics .

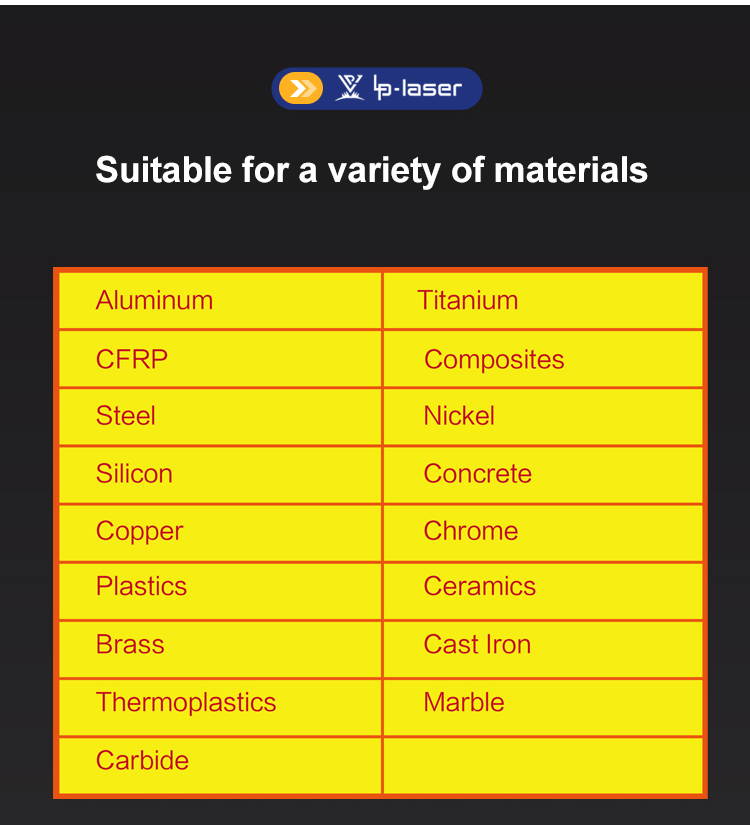

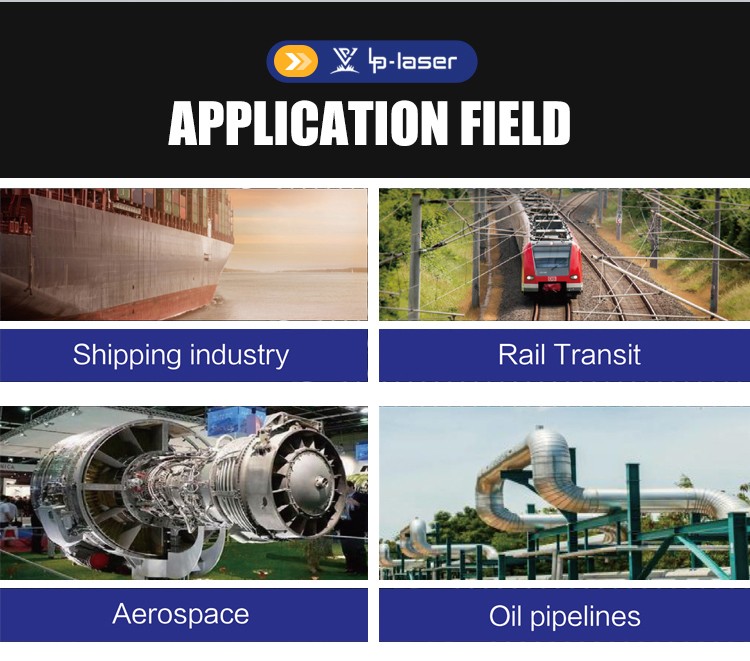

4. Wide applicability : suitable for all kinds of materials and surfaces, including metal, plastic, glass, etc., widely used in manufacturing, cultural relics protection, aerospace and other fields .

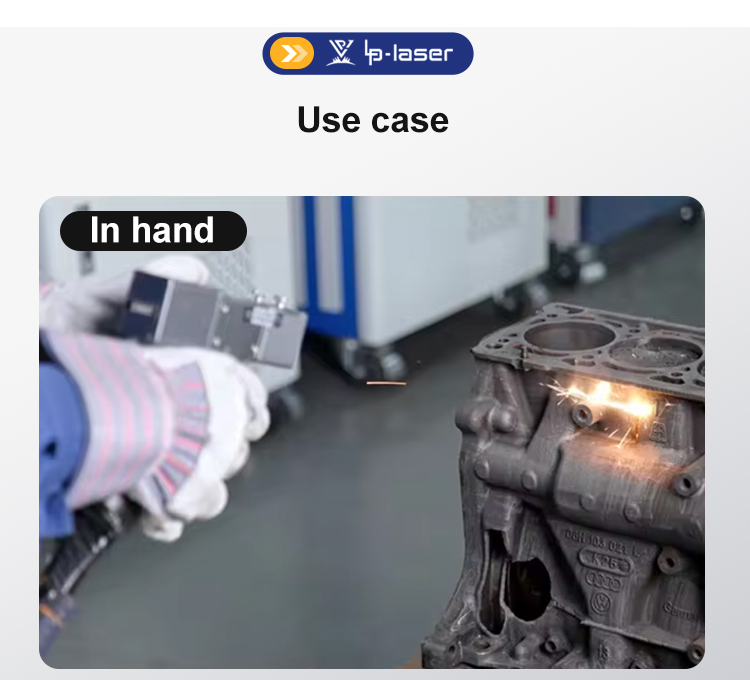

5. Easy operation : modern handheld laser cleaning machine is usually equipped with advanced control system, simple operation, high stability, low maintenance cost .

6. Versatility : can be used to remove oil, rust, coating and other pollutants, suitable for a variety of complex shape and material surface cleaning .

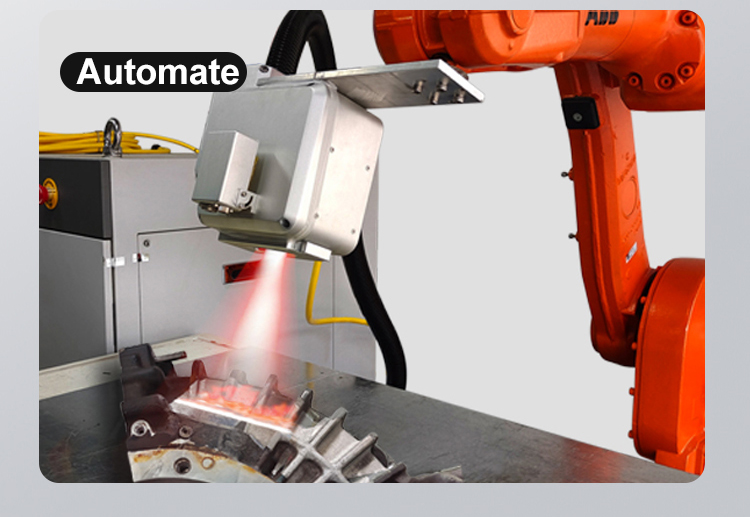

7. Intelligent control : equipped with intelligent control system, can automatically identify the type of stains, adjust cleaning parameters, automatic operation

Hand-held laser cleaning machine is a kind of equipment that uses high energy laser beam to clean the surface of objects. It has the characteristics of high efficiency, environmental protection and non-destructive . The working principle is to irradiate the surface of the object by a laser beam of a specific wavelength, so that the dirt, rust or coating will evaporate or peel off immediately after absorbing the laser energy, forming plasma and shock wave, thus turning the pollutants into fragments and removing .

| Model: | HLC-P100W | HLC-P200W |

| Operational Voltage: | 220V±10%、50/60Hz customisable:110V、50Hzalternating current | |

| Temperature: | 5℃ ~40℃ | |

| Humidity: | 30-85% Non-Condensing | |

| Power dissipation: | ≤1000W | ≤1500W |

| Power Output: | 100W | 200W |

| Laser Type: | Fibre | |

| Maximum Pulse Energy: | 1.5mJ | |

| Pulse Frequency Range: | 1-3000kHz(Gradient adjustable) | |

| Pulse Width: | 13-500ns tunable | |

| Output Power Instability: | <5% | |

| Wavelength: | 1064 nm | |

| Head Cable Length: | 3 m | |

| Cooling: | Air cooling | |

| Focus Distance: | 160mm | 254mm |

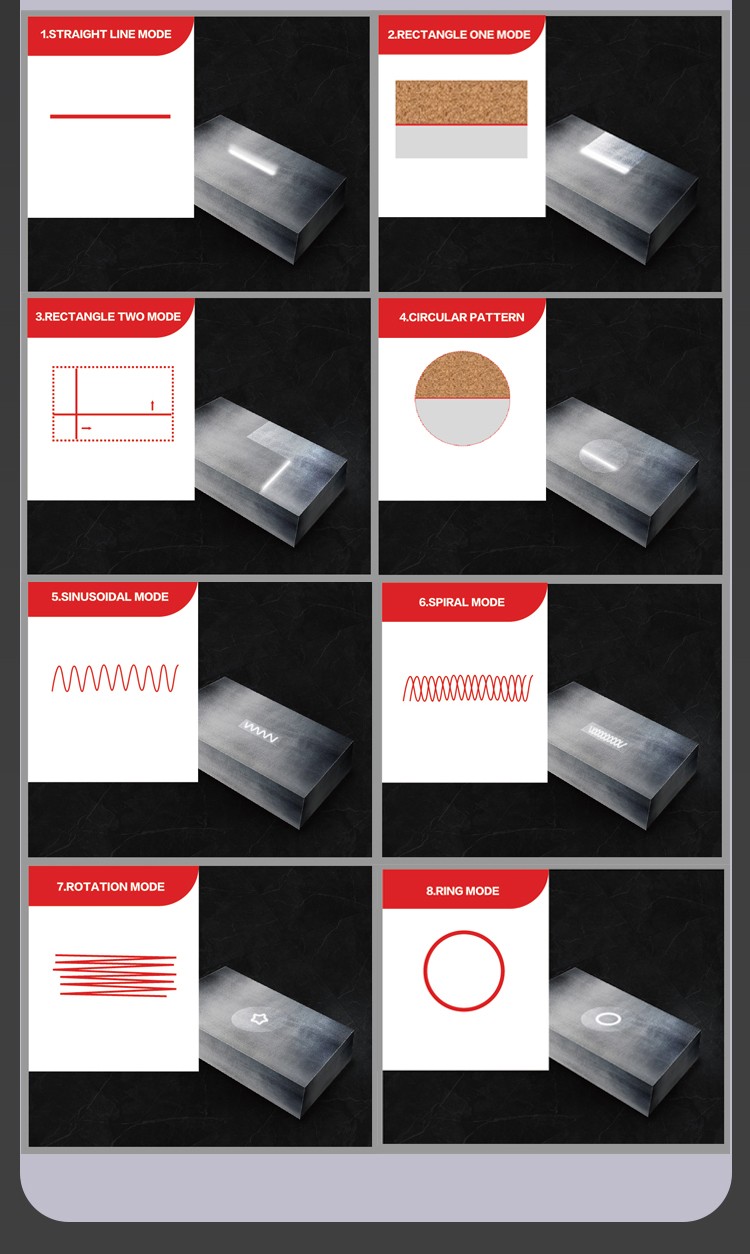

| Scanning mode: | Dual-axis; supports 9 scanning modes | |

| Head Weight: | ≤0.9Kg | |

| Size W x H x D: | About 677mm*298mm*575mm | |

| Entire Unit Weight: | About 38Kg | |

| Packed weight: | About 50Kg | |

| Operation Mode: | Handheld/Automation | |

| Safety Class: | Level IV | |