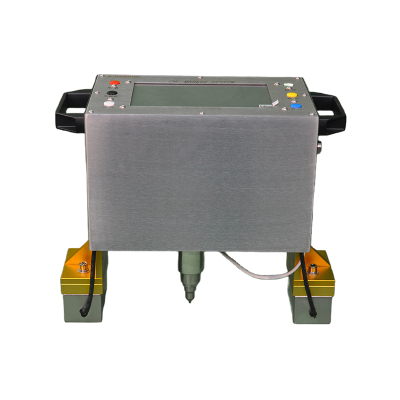

Portable Fiber Laser Cleaning Machine

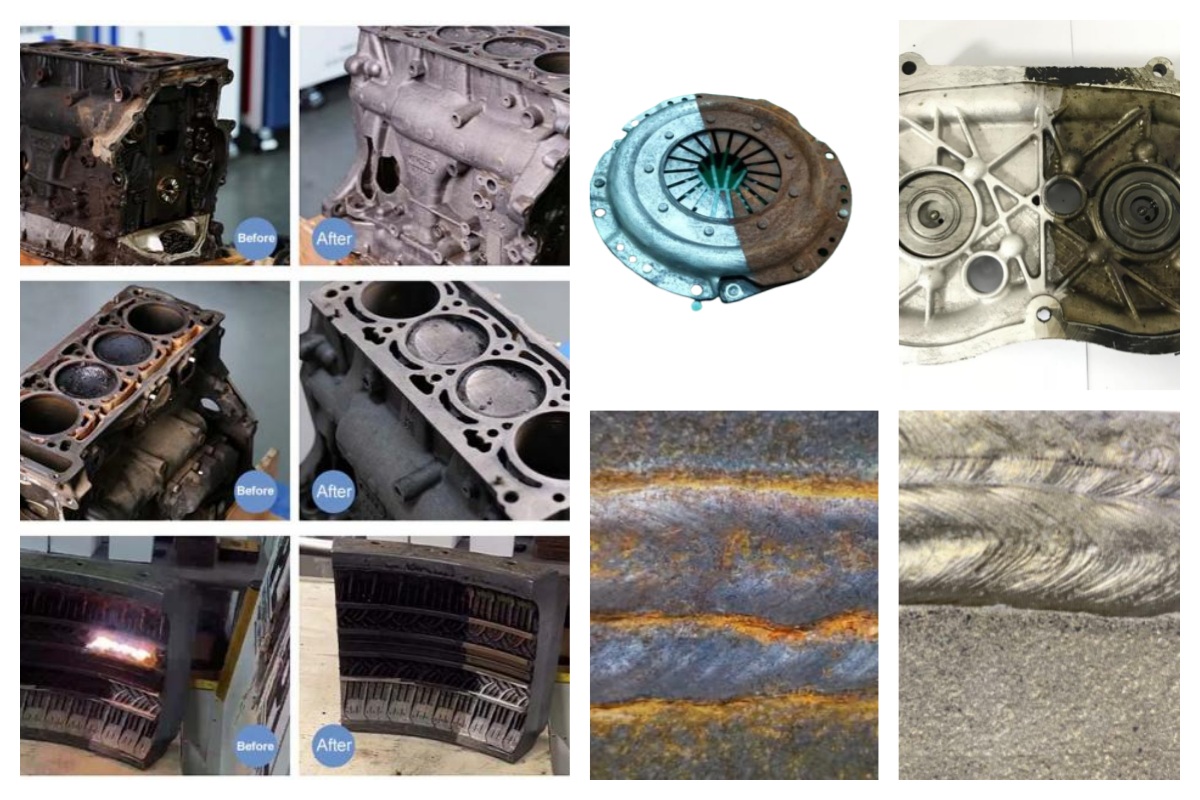

Laser beams are used for cleaning not only for molds, but also for cleaning various workpieces during the manufacturing process. Laser cleaning is a successful alternative to conventional cleaning methods because this process has many advantages. On the one hand, this method does not require cleaning agents and does not require disposal of residual waste, so the operating costs are very low. On the other hand, this method is very precise and protects the surface. Most importantly, the use of laser beams can achieve extremely excellent cleaning results. Various oxides, dust particles and impurities formed by polymer lubricants are very difficult to remove, but they can be evaporated by the laser within a few seconds. The surface cleaned by laser is very suitable for further processing, such as laser welding.

Product Description: Portable Fiber Laser Cleaning Machine is a device that uses laser technology to remove surface dirt, oxides, or coatings from materials. It features the following characteristics and application scope:

Laser cleaning machine focuses the laser beam on the target surface, using high-energy laser pulses to instantly vaporize or shatter the dirt and achieve surface cleaning.

Portable Fiber Laser Cleaning Machine utilizes a fiber laser as the energy source, providing high efficiency, precision, and environmental friendliness.

This portable device is easy to move and flexible to use, suitable for various occasions and environments.

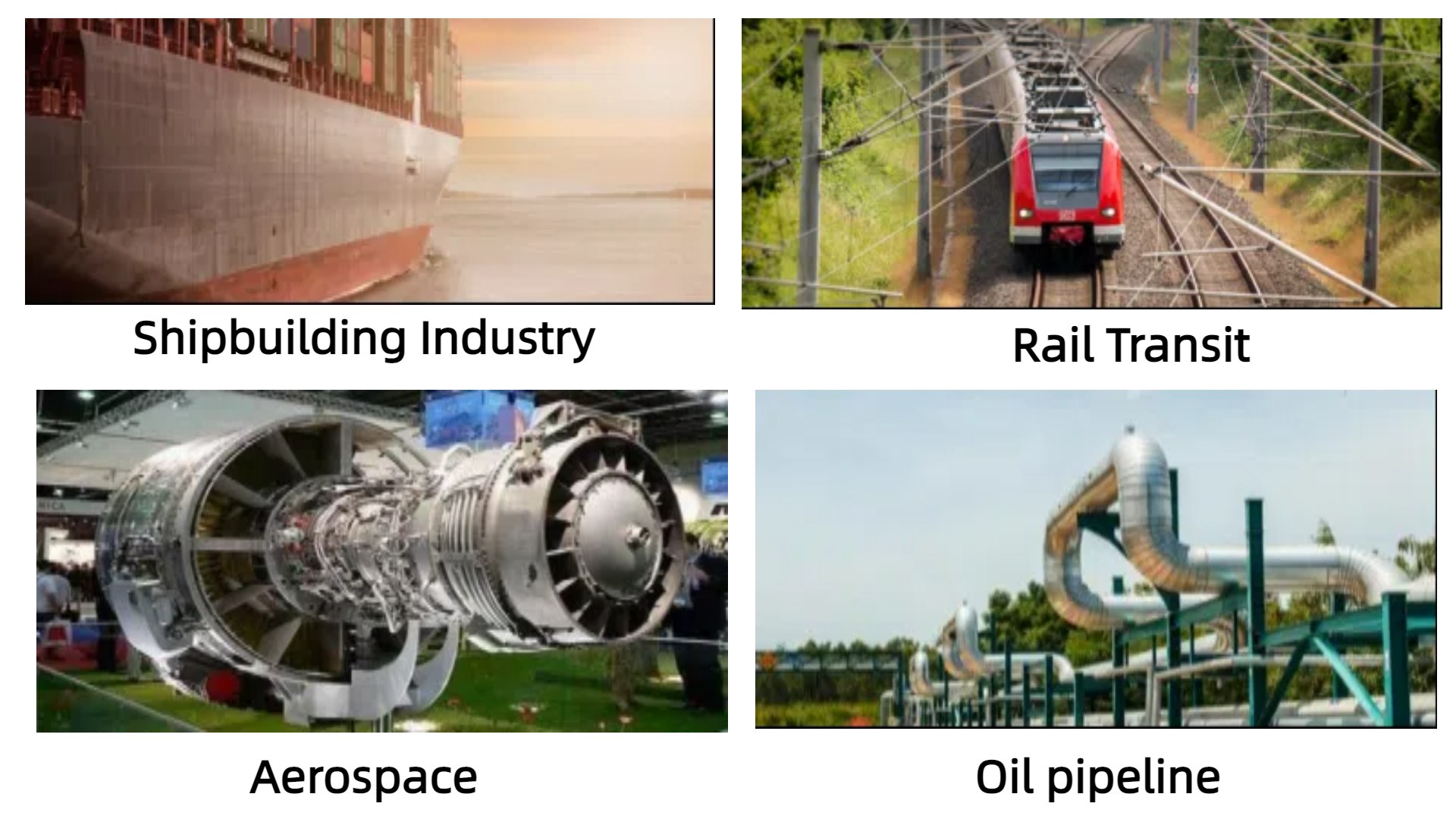

Application Scope:

Metal Material Cleaning: Suitable for cleaning rust, oxidation layers, paint coatings, and more from metal surfaces.

Stone Cleaning: Capable of removing dirt and coatings from stone surfaces and restoring the original luster of the stone.

Automobile Maintenance: Used for cleaning car surfaces, engine components, and more to maintain the cleanliness of the vehicle's appearance.

Cultural Heritage Preservation: Can be employed to clean artifacts, ancient buildings, and remove contaminants to protect cultural heritage.

In summary, Portable Fiber Laser Cleaning Machine is an efficient and environmentally friendly cleaning device that can be applied to the cleaning treatment of various material surfaces.

portable laser cleaning machine parameters:

Model: | HLC-P200W | HLC-P300W |

Operational Voltage: | 220V±10%、50/60Hz customisable:110V、50Hzalternating current | |

Temperature: | 5℃~40℃ | |

Humidity: | 30-85% Non-Condensing | |

Power dissipation: | ≤1500W | ≤1500W |

Power Output: | 200W | 300W |

Laser Type: | fiber | |

Maximum Pulse Energy: | 2mJ | 2mJ/15mJ |

Pulse Frequency Range: | 1-3000kHz(Gradient adjustable) | 1-3000kHz(Gradient adjustable) |

Pulse Width: | 13-500ns adjustable | 13-500ns adjustable |

Output Power Instability: | <5% | |

Wavelength: | 1064 nm | |

Head Cable Length: | 3 m | 5 m |

Cooling: | air cooling | |

Focus Distance: | 210mm | 210mm |

Scanning mode: | Dual-axis; supports 9 scanning modes | |

Head Weight: | ≤0.9Kg | ≤1.25Kg |

Size W x H x D: | about 617mm*469mm*291mm | |

Box Dimensions | about 760mm*560mm*460mm | |

Entire Unit Weight: | about 28Kg | about 29Kg |

Packed weight: | about 28.2Kg | about 49Kg |

Operation Mode: | Handheld/Automation | Handheld/Automation |

Safety Class: | IV level | IV level |