Multifunctional Handheld Laser Cleaning Machine

1. Efficient cleaning : laser cleaning can achieve fast operation, greatly shorten the cleaning cycle, improve production efficiency .

2. Environmental protection and pollution-free : no need to use chemical solvents or cleaning solution, to avoid the problem of secondary pollution, clean down the waste volume is small and easy to store and deal with .

3. Non-destructive cleaning : laser cleaning has minimal damage to the substrate, especially suitable for the cleaning and protection of precision parts or historical relics .

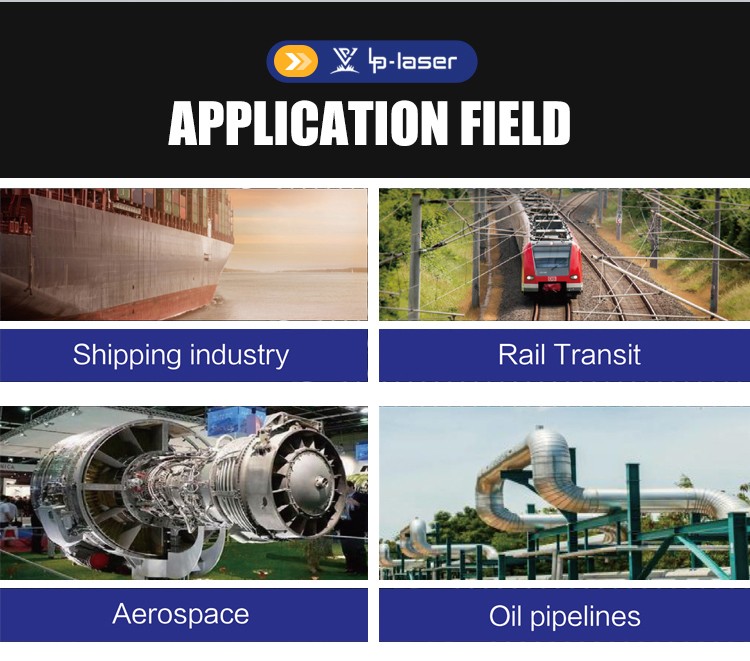

4. Wide applicability : suitable for all kinds of materials and surfaces, including metal, plastic, glass, etc., widely used in manufacturing, cultural relics protection, aerospace and other fields .

5. Easy operation : modern handheld laser cleaning machine is usually equipped with advanced control system, simple operation, high stability, low maintenance cost .

6. Versatility : can be used to remove oil, rust, coating and other pollutants, suitable for a variety of complex shape and material surface cleaning .

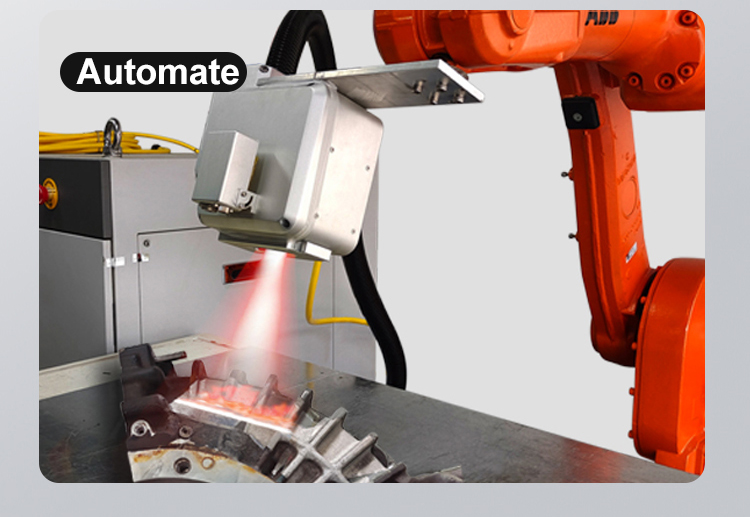

7. Intelligent control : equipped with intelligent control system, can automatically identify the type of stains, adjust cleaning parameters, automatic operation

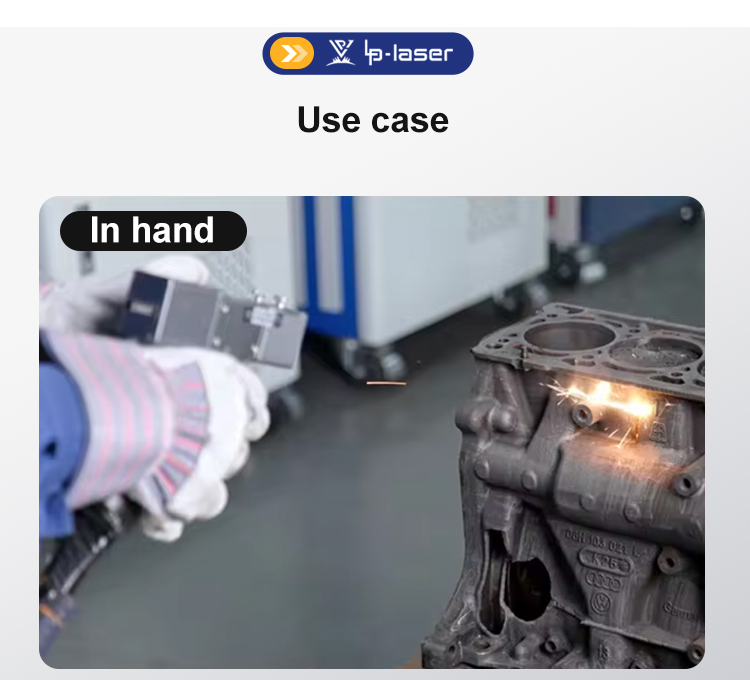

A Hand-held laser cleaning machine utilizes a high-energy laser beam to remove contaminants from object surfaces. It offers advantages such as high efficiency, eco-friendliness, and non-destructive cleaning. The mechanism involves directing a laser of a specific wavelength onto the material’s surface, where contaminants like rust, dirt, or coatings absorb the laser energy and rapidly vaporize or detach. This process generates plasma and shock waves, breaking down the pollutants into particles that are effectively eliminated.

| Model: | HLC-P100W | HLC-P200W |

| Operational Voltage: | 220V±10%、50/60Hz customisable:110V、50Hzalternating current | |

| Temperature: | 5℃ ~40℃ | |

| Humidity: | 30-85% Non-Condensing | |

| Power dissipation: | ≤1000W | ≤1500W |

| Power Output: | 100W | 200W |

| Laser Type: | Fibre | |

| Maximum Pulse Energy: | 1.5mJ | |

| Pulse Frequency Range: | 1-3000kHz(Gradient adjustable) | |

| Pulse Width: | 13-500ns tunable | |

| Output Power Instability: | <5% | |

| Wavelength: | 1064 nm | |

| Head Cable Length: | 3 m | |

| Cooling: | Air cooling | |

| Focus Distance: | 160mm | 254mm |

| Scanning mode: | Dual-axis; supports 9 scanning modes | |

| Head Weight: | ≤0.9Kg | |

| Size W x H x D: | About 677mm*298mm*575mm | |

| Entire Unit Weight: | About 38Kg | |

| Packed weight: | About 50Kg | |

| Operation Mode: | Handheld/Automation | |

| Safety Class: | Level IV | |

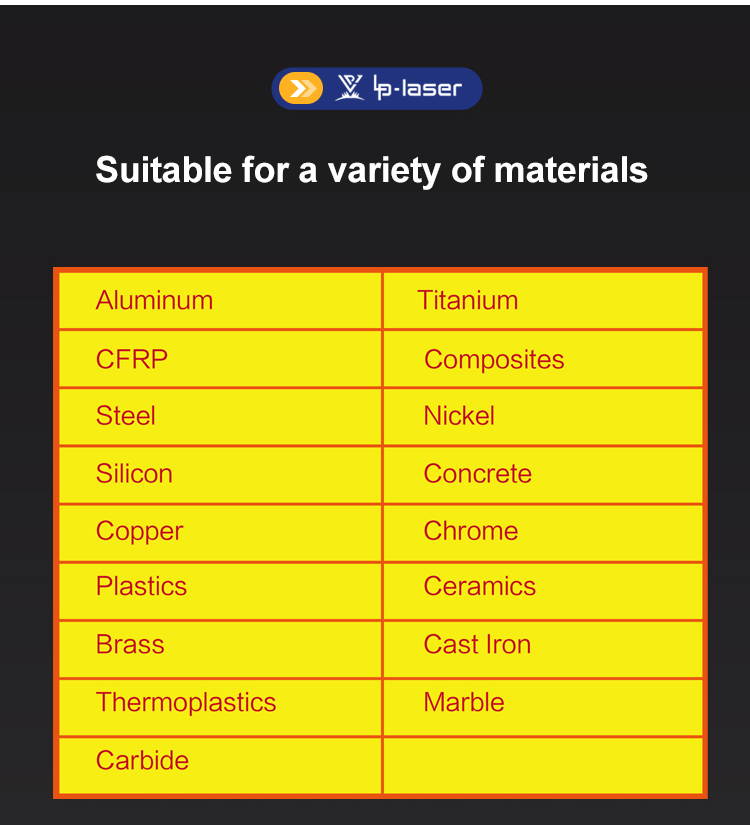

1. Material Compatibility

Q: Which materials are compatible with laser cleaning technology?

A: Our laser cleaner is engineered for versatile material applications, including but not limited to:

Metals: Aluminium, Steel, Copper, Titanium, Nickel, Chromium, Cast Iron

Composites & Polymers: Carbon Fibre Reinforced Plastics (CFRP), Thermoplastics, General Plastics

Industrial Materials: Silicon, Ceramics, Carbide

Architectural Surfaces: Marble, Stone (with precision down to dust-level details)

Note: Custom parameter presets are available for optimal cleaning performance across materials.

2. Substrate Safety

Q: Does laser cleaning risk damaging the underlying material?

A: Our system employs two advanced cleaning protocols with distinct advantages:

Pulse Mode: Delivers ultra-fine control (µm-level precision), minimizing thermal impact—ideal for delicate substrates.

Continuous Mode: Maximizes throughput for industrial-scale cleaning while maintaining safety.

Proprietary Algorithm Assurance: Through adaptive power modulation and real-time feedback, we achieve near-zero substrate damage (validated per ISO 18535:2016 standards).

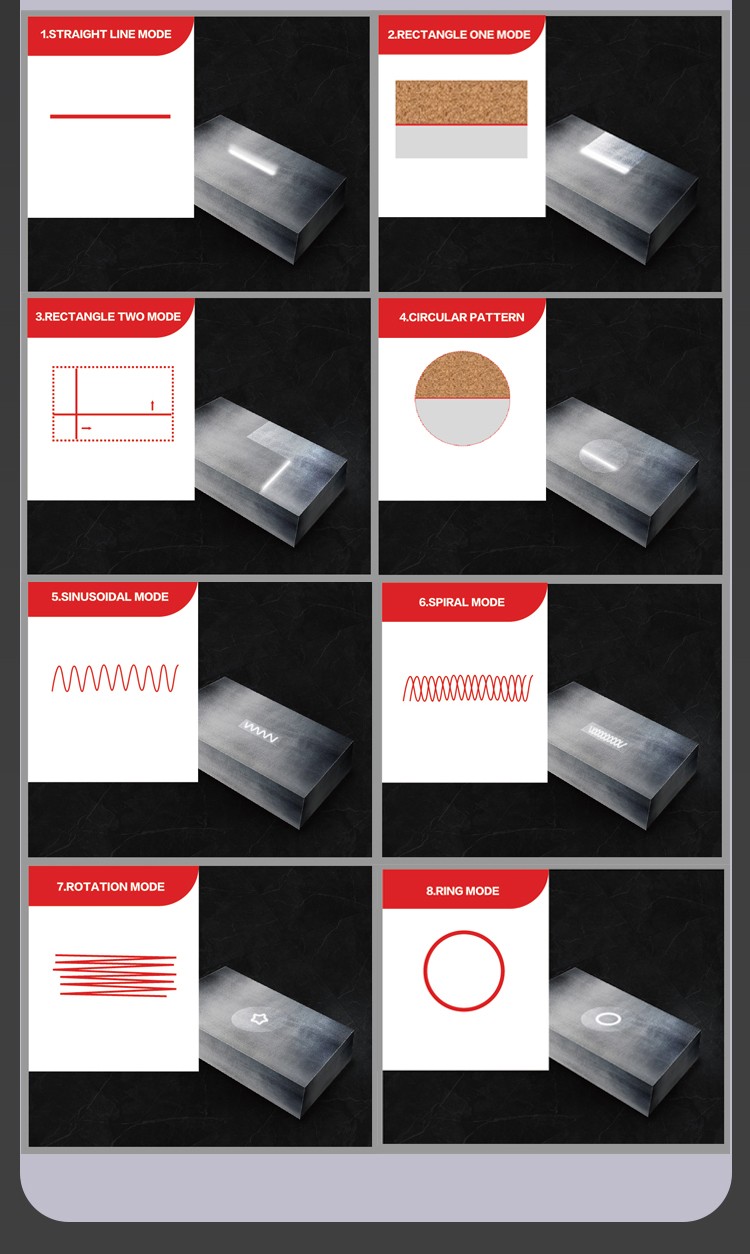

3. Cleaning Modes & Flexibility

Q: What cleaning patterns does the system support?

A: Designed for complex surface geometries, the device offers 9 programmable modes:

Standard Patterns: Linear, Rectangle (I/II), Circle, Spiral

Dynamic Paths: Sine Wave, Freehand Vector

Specialized Functions: Rotary (for cylindrical objects), Multi-axis Synchronization

Workflow Integration: Modes are selectable via preset recipes or fully customizable via API.

4. Multilingual Support

Q: Is the interface available in my language?

A: The UI natively supports 16 languages, including:

Core Languages: English, 中文简体, 中文繁體, Español, Français, Deutsch

Regional Coverage: Japanese (日本語), Korean (한국어), Russian (Русский)

Localization Features: In-app language switching with dialect-aware terminology.

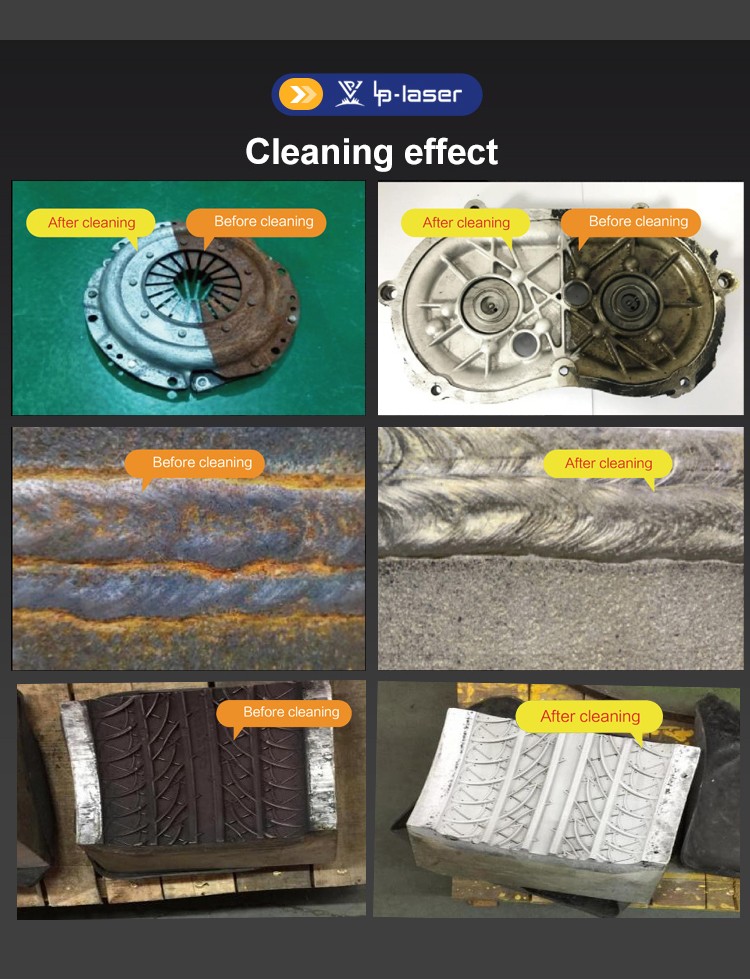

5. Application Scenarios

Q: What industrial use cases does this address?

A: The system is a turnkey solution for:

Surface Restoration: Rust, Paint, Oxide, Oil/Grease, Rubber Residue Removal

Precision Pre-Treatment: Welding/Painting Surface Prep (Sa 2.5 achievable)

Cultural Preservation: Non-abrasive cleaning of stone artifacts and statues

Industry Certifications: Compliant with aerospace (NADCAP), automotive (IATF 16949), and heritage conservation protocols.