Factory direct supply Handheld Laser Cleaning Machine

1. Efficient cleaning : laser cleaning can achieve fast operation, greatly shorten the cleaning cycle, improve production efficiency .

2. Environmental protection and pollution-free : no need to use chemical solvents or cleaning solution, to avoid the problem of secondary pollution, clean down the waste volume is small and easy to store and deal with .

3. Non-destructive cleaning : laser cleaning has minimal damage to the substrate, especially suitable for the cleaning and protection of precision parts or historical relics .

4. Wide applicability : suitable for all kinds of materials and surfaces, including metal, plastic, glass, etc., widely used in manufacturing, cultural relics protection, aerospace and other fields .

5. Easy operation : modern handheld laser cleaning machine is usually equipped with advanced control system, simple operation, high stability, low maintenance cost .

6. Versatility : can be used to remove oil, rust, coating and other pollutants, suitable for a variety of complex shape and material surface cleaning .

7. Intelligent control : equipped with intelligent control system, can automatically identify the type of stains, adjust cleaning parameters, automatic operation

The handheld laser cleaning machine is a high - efficiency, eco - friendly and non - destructive device that uses a high - energy laser beam to clean object surfaces. It irradiates the surface with a laser of a specific wavelength, causing dirt, rust or coating to evaporate/peel off upon absorbing the energy, forming plasma and shock waves that break the pollutants into fragments for removal.

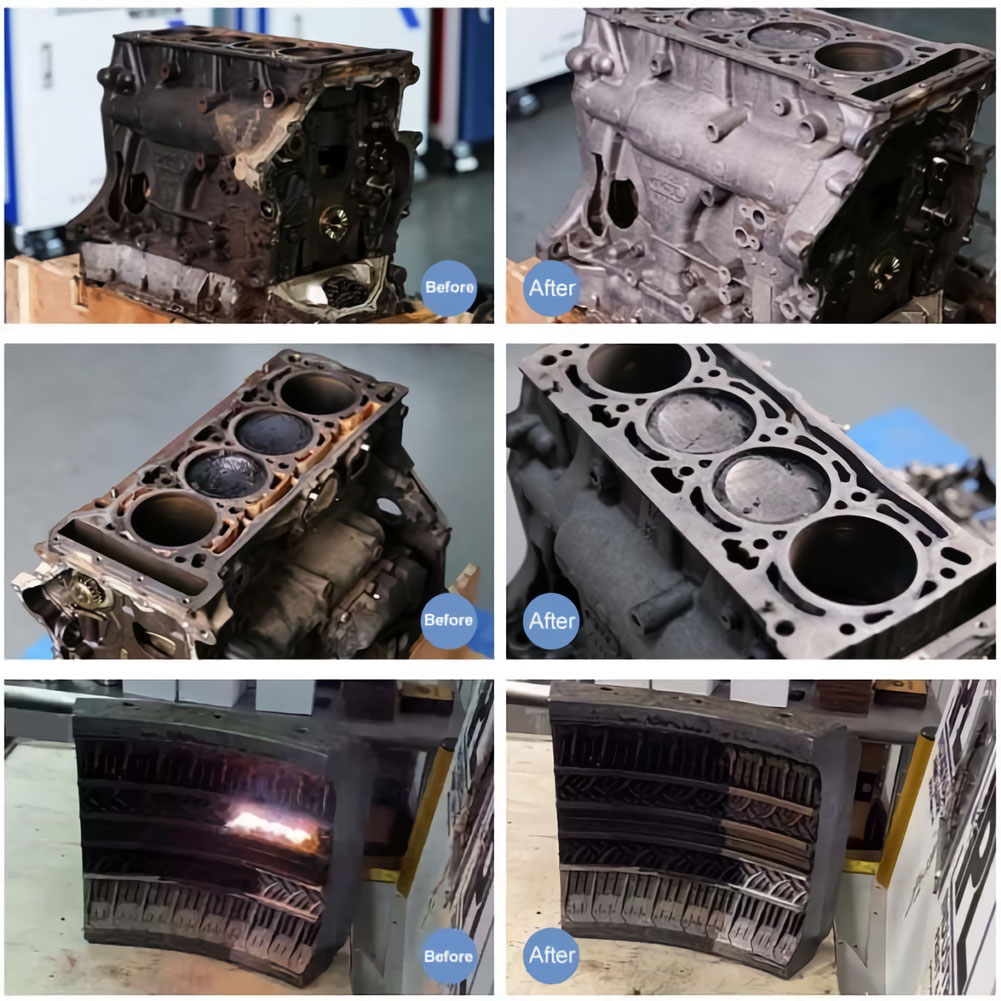

Sample Photos:

The Handheld Laser Cleaning Machine uses laser rays to clean not only moulds and dies, but also all kinds of workpieces in the process. The success of laser cleaning as an alternative to conventional cleaning methods is due to the many advantages of this process. On the one hand, it does not require cleaning agents or the disposal of residual waste, and therefore has very low operating costs. On the other hand, it is very precise and protects the surface. Above all, the use of laser rays achieves excellent cleaning results. All kinds of oxides, dust particles and especially impurities formed by polymer lubricants, which are very difficult to remove, can be evaporated by the laser in a matter of seconds. The laser-cleaned surfaces are ideally suited for further processing, such as laser welding.

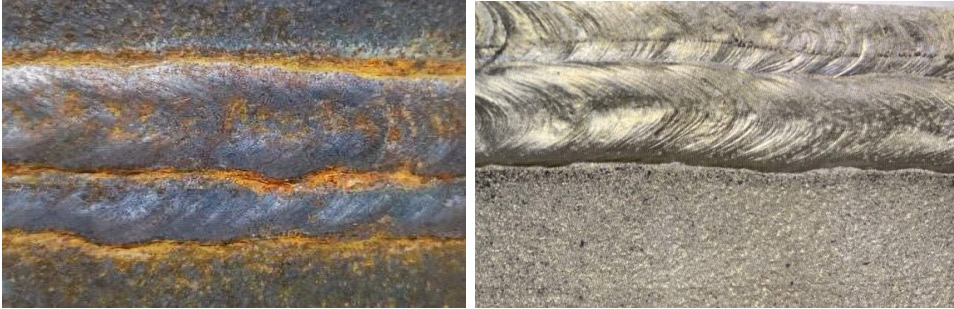

Sample Photos:

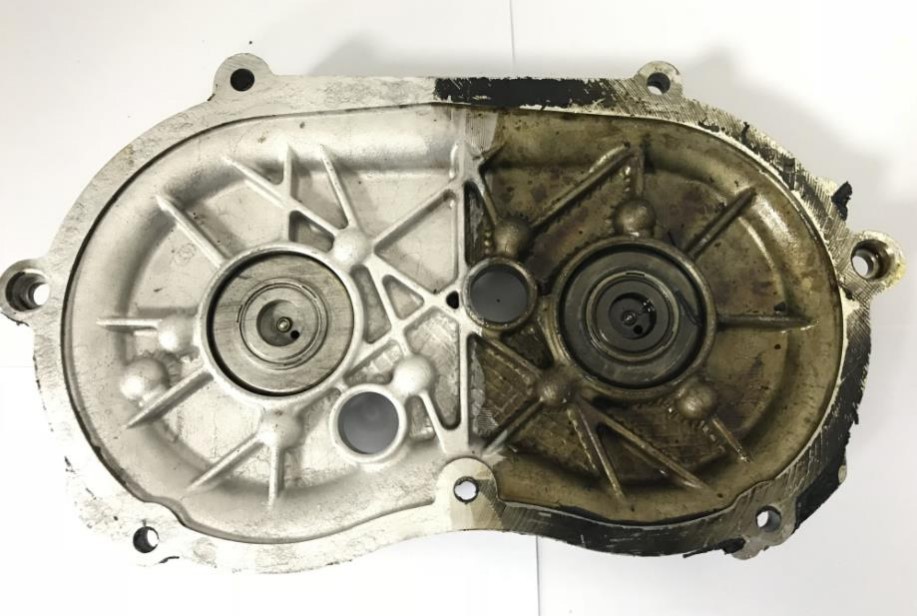

Sample Photos:

Sample Photos:

Product Parameter:

Model: | HLC-P100W | HLC-P200W |

Operational Voltage: | 220V±10%、50/60Hz customisable:110V、50Hzalternating current | |

Temperature: | 5℃ ~40℃ | |

Humidity: | 30-85% Non-Condensing | |

Power dissipation: | ≤1000W | ≤1500W |

Power Output: | 100W | 200W |

Laser Type: | Fibre | |

Maximum Pulse Energy: | 1.5mJ | 1.5mJ |

Pulse Frequency Range: | 1-3000kHz(Gradient adjustable) | 1-3000kHz(Gradient adjustable) |

Pulse Width: | 13-500ns tunable | 13-500ns tunable |

Output Power Instability: | <5% | |

Wavelength: | 1064 nm | |

Head Cable Length: | 3 m | 3 m |

Cooling: | Air cooling | |

Focus Distance: | 160mm | 254mm |

Scanning mode: | Dual-axis; supports 9 scanning modes | |

Head Weight: | ≤0.9Kg | ≤0.9Kg |

Size W x H x D: | About 677mm*298mm*575mm | |

Entire Unit Weight: | About 38Kg | About 38Kg |

Packed weight: | About 50Kg | About 50Kg |

Operation Mode: | Handheld/Automation | |

Safety Class: | Level IV | |

FAQ

1.Q: How does the cost - effectiveness of a laser cleaning machine compare to traditional cleaning methods?

A: Laser cleaning machines are highly cost - effective in the long run. Although the initial investment might seem higher compared to some basic traditional cleaning tools, they have zero or minimal consumables. For example, unlike sandblasting that requires a continuous supply of abrasive materials, or chemical cleaning that needs a large amount of cleaning agents, laser cleaning mainly consumes electricity. Also, laser cleaning significantly reduces labor costs due to its high - speed operation. It can clean large areas in a short time, increasing productivity. Moreover, the non - contact nature of laser cleaning reduces the risk of damage to the workpiece, minimizing rework and material waste, which further saves costs.

2.Q: What are the key functions of a laser cleaning machine, and how do they contribute to its value?

A: Laser cleaning machines have several key functions. Firstly, they can precisely remove various contaminants such as rust, paint, oil, and oxidation layers from the surface of different materials including metals, ceramics, and some plastics. This high - precision cleaning is crucial for industries where surface quality is vital, like aerospace and electronics. Secondly, the non - contact cleaning function ensures that the base material remains undamaged during the cleaning process. This is a huge advantage over abrasive cleaning methods. For instance, when cleaning delicate parts in the medical device industry, the non - contact feature of laser cleaning machines helps maintain the integrity of the components. Thirdly, laser cleaning machines can work in various environments, both indoor and outdoor, and can be easily integrated into existing production lines, enhancing their versatility and value.

3.Q: Are there different power options for laser cleaning machines, and how do they affect performance and cost?

A: Yes, laser cleaning machines come in a range of power options, typically from low - power models around 50W to high - power ones up to 3000W or more. Low - power machines are more suitable for small - scale cleaning tasks or for cleaning delicate materials where high power might cause damage. They are generally more affordable in terms of initial cost and also consume less electricity, so the operating cost is relatively low. High - power laser cleaning machines, on the other hand, are designed for large - scale industrial applications such as cleaning large steel structures, ship hulls, or industrial pipelines. They can clean much larger areas at a faster rate, significantly increasing productivity. However, they usually have a higher initial purchase price and consume more power, but the cost per unit area cleaned can be lower when dealing with large - volume cleaning jobs due to their high efficiency.