Advanced Handheld Laser Cleaning Machine

1. Efficient cleaning : laser cleaning can achieve fast operation, greatly shorten the cleaning cycle, improve production efficiency .

2. Environmental protection and pollution-free : no need to use chemical solvents or cleaning solution, to avoid the problem of secondary pollution, clean down the waste volume is small and easy to store and deal with .

3. Non-destructive cleaning : laser cleaning has minimal damage to the substrate, especially suitable for the cleaning and protection of precision parts or historical relics .

4. Wide applicability : suitable for all kinds of materials and surfaces, including metal, plastic, glass, etc., widely used in manufacturing, cultural relics protection, aerospace and other fields .

5. Easy operation : modern handheld laser cleaning machine is usually equipped with advanced control system, simple operation, high stability, low maintenance cost .

6. Versatility : can be used to remove oil, rust, coating and other pollutants, suitable for a variety of complex shape and material surface cleaning .

7. Intelligent control : equipped with intelligent control system, can automatically identify the type of stains, adjust cleaning parameters, automatic operation

Handheld Laser Cleaning Machine

A handheld laser cleaning machine is a portable device that employs a high-energy laser beam to effectively remove surface contaminants from various materials. Key features include high efficiency, eco-friendliness, and non-destructive cleaning, making it ideal for industrial and precision applications.

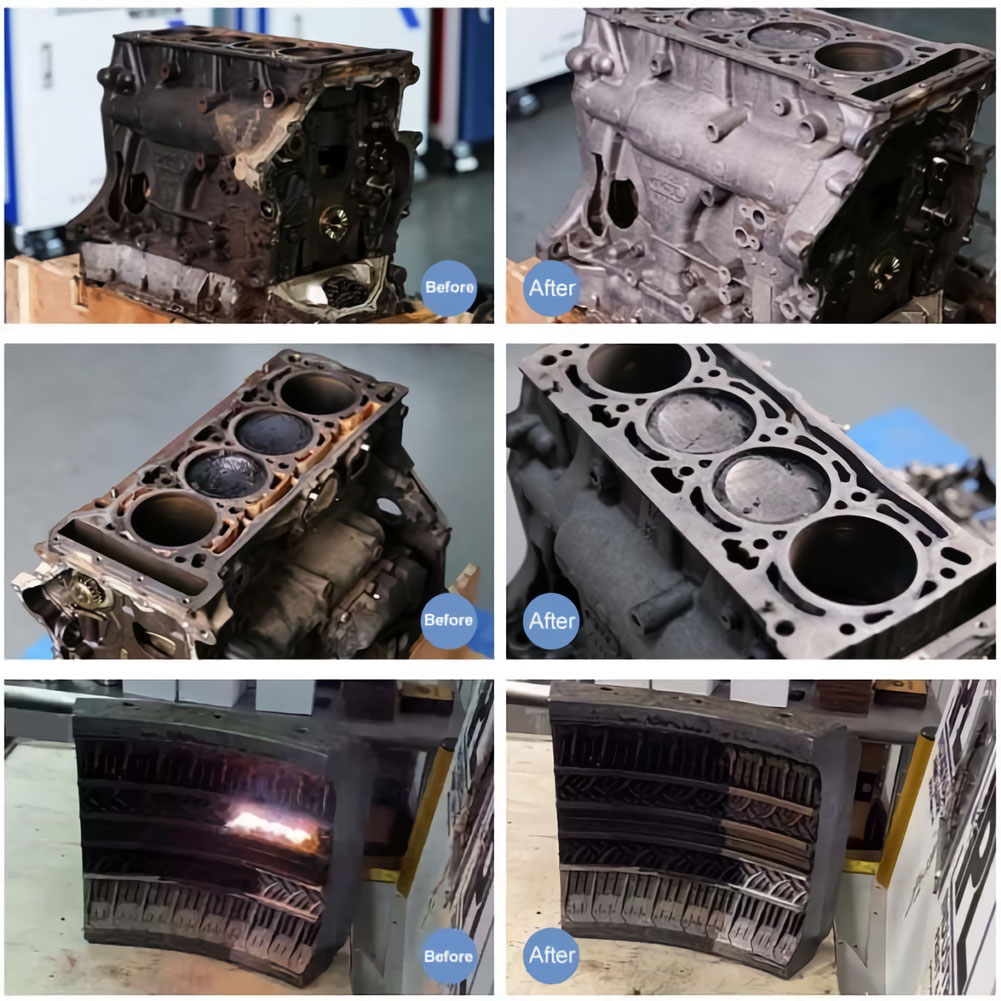

Sample Photos:

Working Principle:

The machine emits a laser beam at a specific wavelength, which is absorbed by contaminants (e.g., dirt, rust, or coatings) on the target surface. Upon absorption, the contaminants rapidly evaporate or delaminate, generating plasma and shock waves in the process. This energy conversion effectively disintegrates the pollutants into fine particles, which are subsequently removed, leaving the underlying surface clean and intact.

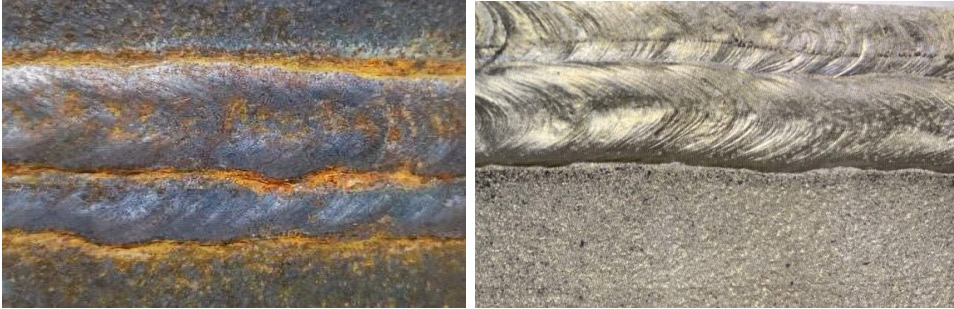

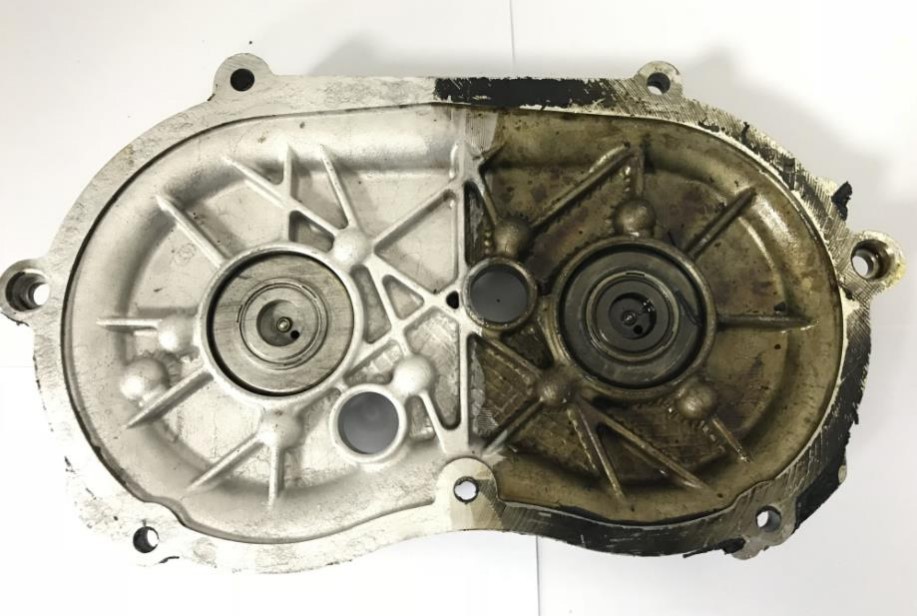

Sample Photos:

Product Parameter:

The Handheld Laser Cleaning Machine is a versatile tool designed for precision surface cleaning, suitable for molds, dies, and a wide range of workpieces in industrial processes. Its growing adoption as a replacement for conventional cleaning methods stems from several key advantages:

Cost-Effective & Eco-Friendly

Eliminates the need for chemical cleaning agents and eliminates waste disposal issues, resulting in minimal operating costs.

Environmentally friendly operation with zero hazardous byproducts.

Precision & Surface Protection

Offers micron-level accuracy, ensuring non-destructive cleaning that preserves the integrity of delicate surfaces.

Prevents mechanical damage or thermal deformation, maintaining the workpiece’s original quality.

Exceptional Cleaning Performance

Effectively removes tough contaminants such as oxides, rust, dust particles, and polymer lubricant residues—even the most stubborn deposits are vaporized in seconds.

The resulting surface is clean, smooth, and residue-free, ideal for subsequent processes like laser welding or painting.

Sample Photos:

Product Parameter:

The Handheld Laser Cleaning Machine uses laser rays to clean not only moulds and dies, but also all kinds of workpieces in the process. The success of laser cleaning as an alternative to conventional cleaning methods is due to the many advantages of this process. On the one hand, it does not require cleaning agents or the disposal of residual waste, and therefore has very low operating costs. On the other hand, it is very precise and protects the surface. Above all, the use of laser rays achieves excellent cleaning results. All kinds of oxides, dust particles and especially impurities formed by polymer lubricants, which are very difficult to remove, can be evaporated by the laser in a matter of seconds. The laser-cleaned surfaces are ideally suited for further processing, such as laser welding.

Sample Photos:

Product Parameter:

Model: | HLC-P100W | HLC-P200W |

Operational Voltage: | 220V±10%、50/60Hz customisable:110V、50Hzalternating current | |

Temperature: | 5℃ ~40℃ | |

Humidity: | 30-85% Non-Condensing | |

Power dissipation: | ≤1000W | ≤1500W |

Power Output: | 100W | 200W |

Laser Type: | Fibre | |

Maximum Pulse Energy: | 1.5mJ | 1.5mJ |

Pulse Frequency Range: | 1-3000kHz(Gradient adjustable) | 1-3000kHz(Gradient adjustable) |

Pulse Width: | 13-500ns tunable | 13-500ns tunable |

Output Power Instability: | <5% | |

Wavelength: | 1064 nm | |

Head Cable Length: | 3 m | 3 m |

Cooling: | Air cooling | |

Focus Distance: | 160mm | 254mm |

Scanning mode: | Dual-axis; supports 9 scanning modes | |

Head Weight: | ≤0.9Kg | ≤0.9Kg |

Size W x H x D: | About 677mm*298mm*575mm | |

Entire Unit Weight: | About 38Kg | About 38Kg |

Packed weight: | About 50Kg | About 50Kg |

Operation Mode: | Handheld/Automation | |

Safety Class: | Level IV | |