Cheap Pulsed Laser Cleaning Machine

1. Efficient cleaning : pulsed laser cleaning machine can quickly remove surface dirt, rust, oxide, oil and dirt, high cleaning efficiency, especially suitable for high-speed cleaning .

2. Non-contact cleaning : Compared with traditional mechanical methods, laser cleaning is a non-contact cleaning process that will not wear or damage the surface and can maintain the original quality of the material .

3. Environmental protection : laser cleaning does not produce chemical waste or dust, reducing the pollution to the environment. There is usually no need to use chemical cleaning agents, with environmental advantages .

4. Accurate control : the parameters of laser cleaning can be accurately controlled through the automatic system to meet the cleaning requirements of different materials .

5. Low damage : in the process of laser cleaning, pollutants absorb energy gasification removal, or the substrate absorbs laser to produce thermal stress stripping of pollutants, the damage to the substrate material is minimal, and even no damage to the substrate .

6. Wide range of application : suitable for metal or glass surface coating layer removal, rapid paint removal, rust removal, removal of grease, resin, glue, dust, stains, production residue .

Laser Cleaning Machines: A Superior Cleaning Solution

Efficient, Cost-Effective & Safe

Laser cleaning machines offer a highly efficient, cost-effective, and safer alternative to traditional cleaning methods (such as chemical, abrasive, or manual techniques). By leveraging advanced laser technology, they eliminate contaminants without secondary waste or hazardous byproducts.

Precision Contaminant Removal

Our systems effectively remove:

Industrial Coatings: Paint, resin, rubber mold residue

Surface Corrosion: Rust, oxidation layers

Oils & Contaminants: Grease, stains, dirt (down to micron-level precision)

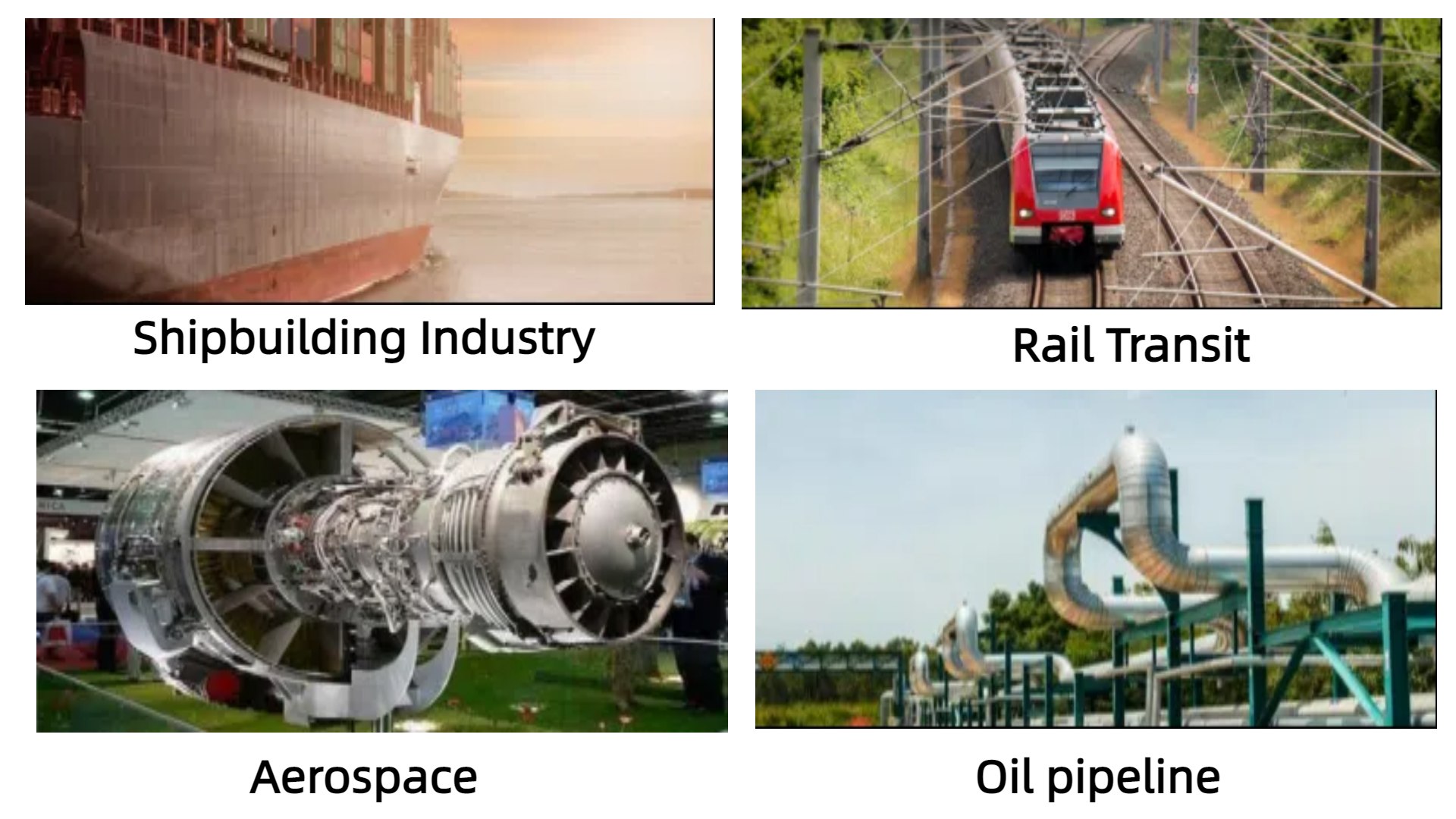

Wide-Ranging Industrial Applications

Deployed across critical industries, including:

Transportation: Automotive, aerospace, rail, shipbuilding

Heavy Machinery: High-end CNC machine tools, turbine components

Manufacturing & Maintenance: Rubber molding, steam turbine repair

Sustainability: Eco-friendly surface treatment for environmental compliance

Pulsed Laser Cleaning Machines

Our pulsed laser systems deliver:

✔ Ultra-Fine Cleaning – Minimized thermal impact for delicate substrates

✔ Non-Abrasive Process – Zero mechanical wear on surfaces

✔ Adaptive Control – Smart algorithms adjust power in real-time for optimal results

Why Choose Laser Cleaning?

Lower Operational Costs – Reduced consumables vs. chemical/sandblasting

Enhanced Safety – No toxic chemicals or airborne particulates

Environmentally Friendly – No secondary pollution, aligns with green manufacturing

Pulsed Laser Cleaning Machine:

Model: | HLC-P200W | HLC-P300W | HLC-P300W(water cooling) |

Operational Voltage: | 220V±10%、50/60Hz customisable:110V、50Hzalternating current | ||

Temperature: | 5℃~40℃ | ||

Humidity: | 30-85% Non-Condensing | ||

Power dissipation: | ≤1500W | ≤2000W | ≤4000W |

Power Output: | 200W | 300W | 300W |

Laser Type: | fibre | ||

Maximum Pulse Energy: | 1.5mJ/2mJ/5mJ | 1.5mJ/5mJ | 12.5mJ |

Pulse Frequency Range: | 1-4000kHz(Gradient adjustable) | 1-4000kHz(Gradient adjustable) | 1-4000kHz(Gradient adjustable) |

Pulse Width: | 2-500ns adjustable | 2-500ns adjustable | 2-500ns adjustable |

Output Power Instability: | <5% | ||

Wavelength: | 1064 nm | ||

Head Cable Length: | 5 m | 5 m | 5 m |

Cooling: | air cooling | water cooling | |

Focus Distance: | 210mm | 210mm | 210mm |

Scanning mode: | Dual-axis; supports 9 scanning modes | ||

Head Weight: | ≤0.9Kg | ≤1.25Kg | |

Size W x H x D: | about 629mm*341mm*734mm | about 982mm*458mm*791mm | |

Box Dimensions | about 800mm*470mm*880mm | about 1130mm*580mm*1050mm | |

Entire Unit Weight: | about 52Kg | about 135Kg | |

Packed weight: | about 67Kg | about 165Kg | |

Operation Mode: | Handheld/Automation | ||

Safety Class: | IV级 | ||